No welding upper car floor assembly

A non-welding, car bottom technology, applied in elevators, transportation and packaging in buildings, etc., can solve the problems of difficult handling, packing factory assembly, large welding site area, high processing intensity of workers, and achieve disassembly. The effect of improving all aspects of packing and transportation, reducing logistics costs, and avoiding gas and light pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention are described in detail below:

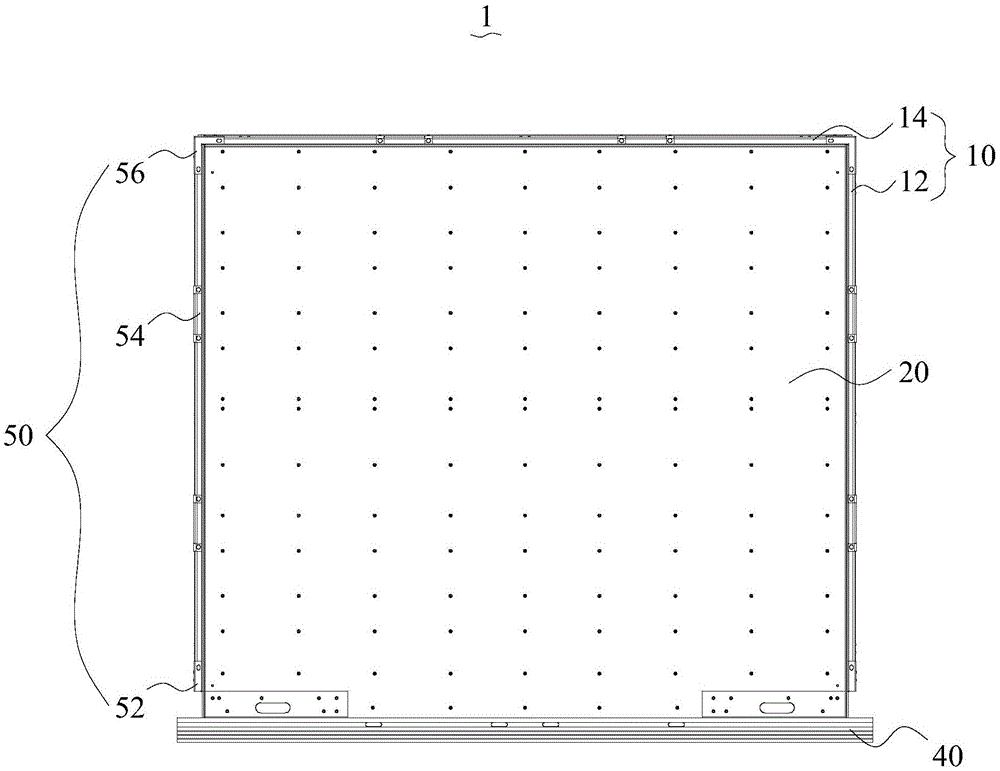

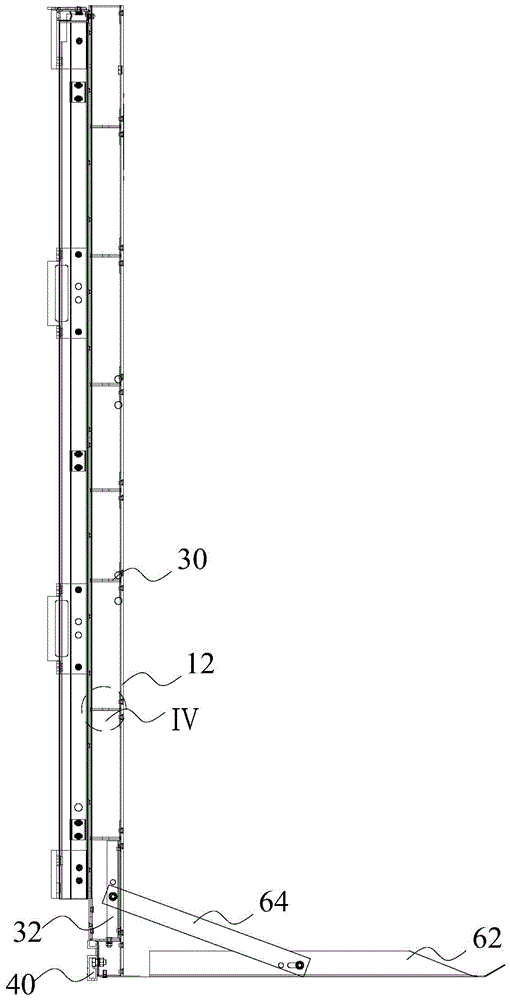

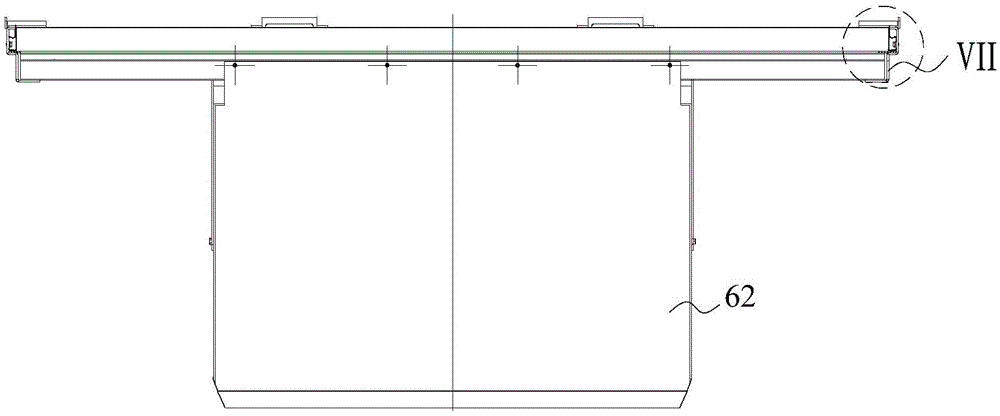

[0026] The non-welding upper car floor assembly 1 of the present invention is used to be assembled on the bottom of the bridge frame of the elevator as a passenger-carrying assembly of the elevator. Such as Figure 1-3 The shown non-welded upper platform assembly 1 includes a frame 10 and a carrier plate 20 . The frame 10 includes a side frame 12 disposed on a side of the supporting board 20 and a rear frame 14 disposed on a rear side of the supporting board 20 . The side frame 12 , the rear frame 14 and the bearing plate 20 constitute the basic frame structure of the upper car floor assembly 1 .

[0027] Such as Figure 4-6 As shown, the carrying board 20 includes a steel plate 22 , a double-sided adhesive or liquid glue layer 24 and a decorative bottom plate 26 . The double-sided adhesive or liquid glue layer 24 sticks the steel plate 22 and the decorative bottom plate 26 together. The decorati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com