Needle detection machine

A needle detection machine and frame technology, applied in the field of needle detection machines, can solve the problems of manual sorting, easy hidden dangers, poor turning effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

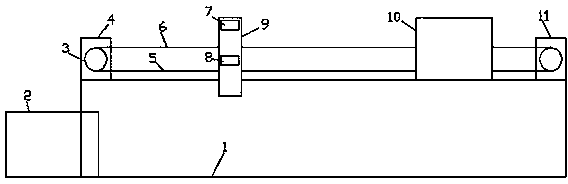

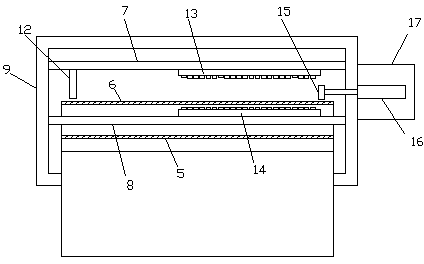

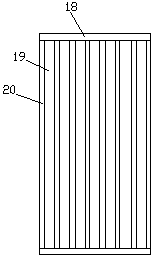

[0012] Such as figure 1 , figure 2 As shown, a needle detector includes a frame 1, a front side plate 11 is provided at the front of the frame 1, a rear side plate 4 is provided at the rear, and a receiving box 2 is provided at the rear and lower part of the frame 1. There are two independent spaces in the box 2, the front side plate 11 and the rear side plate 4 are provided with a transmission shaft 3, the transmission shaft 3 is provided with a conveyor belt 18, and the conveyor belt 18 is driven by the transmission shaft 3 separated by an upper conveyor belt 6 and a lower conveyor belt 5, the frame 1 is provided with a bracket 9, and the bracket 9 is provided with an upper horizontal frame 7 and a lower horizontal frame 8, and the upper horizontal frame 7 Above the upper conveyor belt 6, one side of the lower end surface of the upper horizontal frame 7 is provided with an upper sensor group 13, and the other side is provided with a baffle plate 12, and the lower horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com