Catalytic oil-free gas supply device and catalytic oil-free compression system

A technology of air supply device and catalytic purifier, applied in air quality improvement, chemical instruments and methods, separation methods, etc. The effect of reducing the loss of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

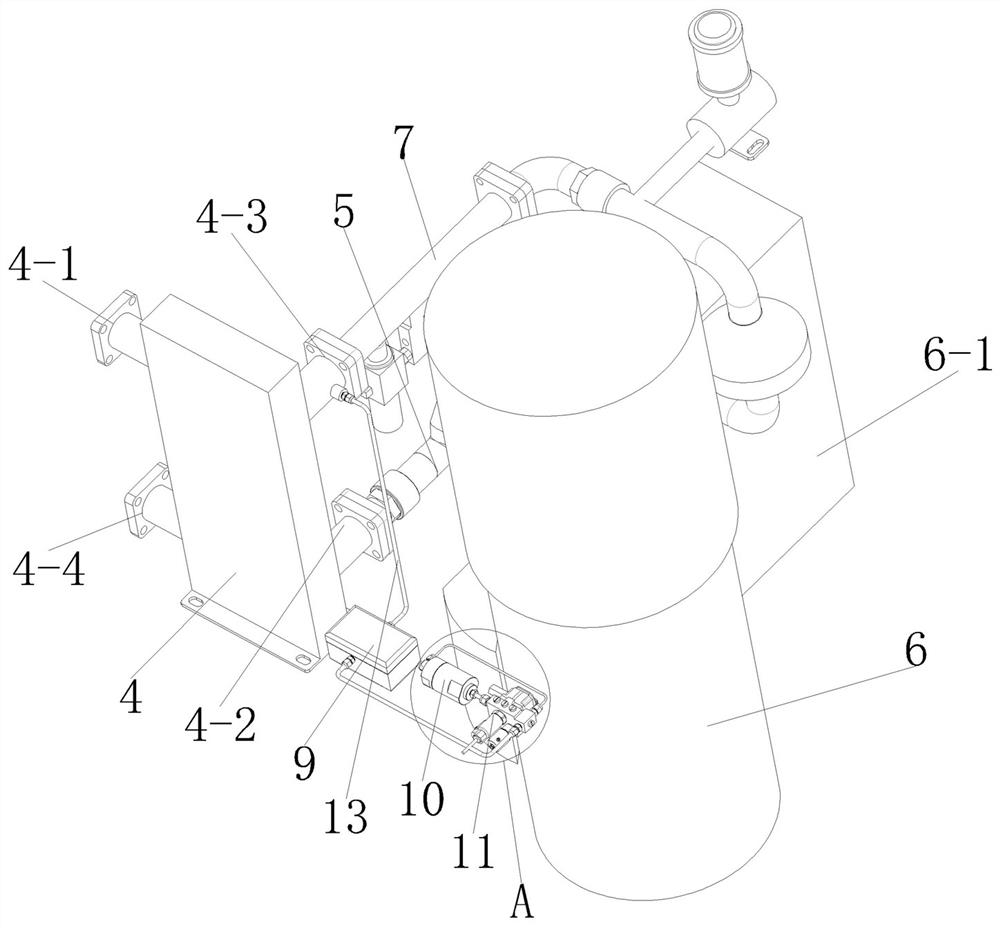

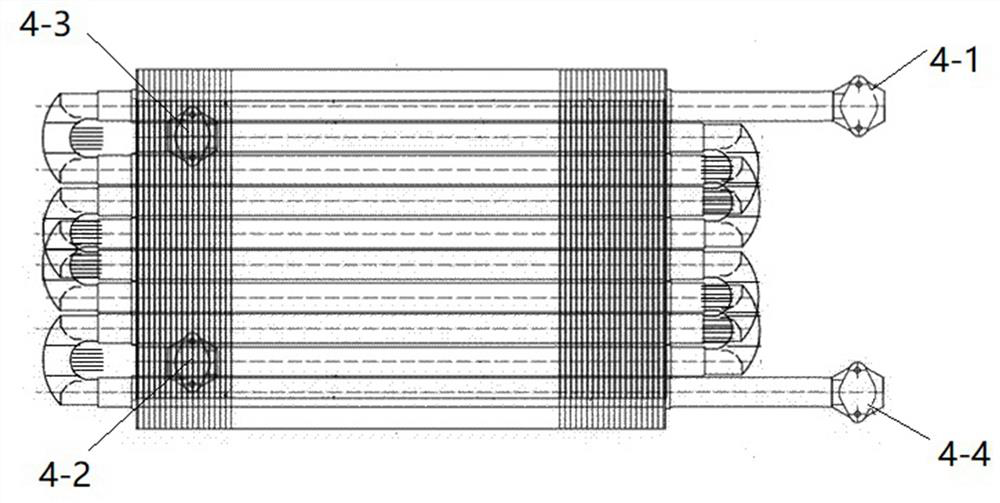

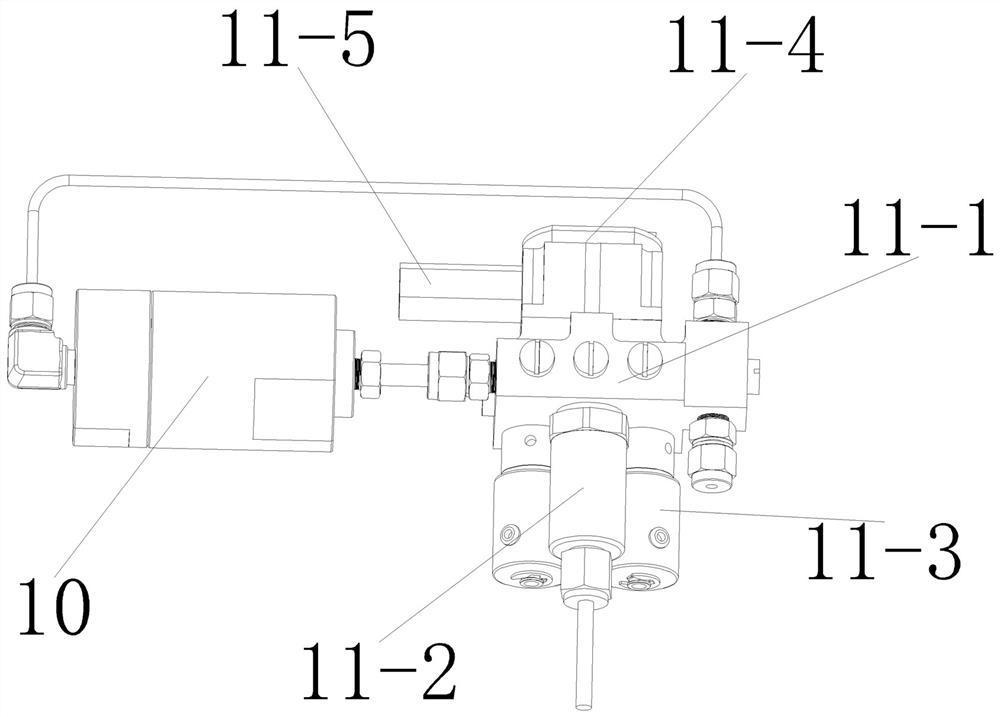

[0029] like figure 1 As shown in , the catalytic oil-free air supply device of the present invention includes a catalytic purifier 6 , an oil content detection device 11 and a heat exchanger 4 . The catalytic purifier 6 includes a heating chamber 6-1, a catalytic purification chamber, a catalytic intake pipe 5 and a catalytic exhaust pipe 7. The catalytic intake pipe 5 introduces compressed gas into the heating chamber 6-1, and the heating chamber 6-1 heats the compressed gas When the temperature reaches 180-200°C, a catalyst is installed in the catalytic purification chamber, and the catalytic purification chamber is wrapped with thermal insulation cotton. The compressed gas enters the catalytic purification chamber after being heated, and undergoes a complex catalytic oxidation reaction under the action of the catalyst to remove oil impurities. That is, the C6+ carbon-containing compounds are decomposed into carbon dioxide and water, and the purified compressed gas is led ou...

Embodiment 2

[0035] The difference between the catalytic oil-free air supply device in the present embodiment and the embodiment 1 is that the second exhaust port 4-4 is provided with an external air supply pipe 8, and the external air supply pipe 8 is connected to the gas-using equipment to the outside. After the compressed gas discharged from the heat exchanger 6 is buffered by a U-shaped heat exchange pipe of the heat exchanger 4, it is led out to the gas-consuming equipment by the external gas supply pipe 8. The external gas supply pipe 8 is also provided with an air-to-air exhaust pipe. The exhaust pipe is used to discharge compressed gas to the air, and the external gas supply pipe 8 is provided with an air supply valve and an exhaust valve. When the detection result of the oil content of the compressed gas reaches the standard, the gas supply valve is opened and the exhaust valve is closed, and the compressed gas flows into the gas equipment through the external gas supply pipe 8; wh...

Embodiment 3

[0037] like Figure 4 As shown in, the catalytic oil-free compression system of the present invention includes a compressor 1, an oil-gas separator 14, a gas-liquid separator 2, and the catalytic oil-free air supply device as described in Embodiment 1 or Embodiment 2, the compressor The air inlet of 1 is provided with an air filter assembly 15 for filtering gas, the exhaust port of the compressor 1 is communicated with the air inlet of the oil-gas separator 14, and the exhaust port of the oil-gas separator 14 is connected with the air-liquid separator 2. The air inlet is connected, the air outlet of the gas-liquid separator 2 is provided with a gas-liquid separation exhaust pipe 3, and the gas-liquid separation exhaust pipe 3 is connected to the first air inlet 4-1 of the heat exchanger 4, that is, through the heat A U-shaped heat exchange pipe in the exchanger 4 communicates with the catalytic intake pipe 5 . The compressor 1 may be a screw type oil-lubricated compressor, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com