Direct-push connecting pipe joint

A technology for connecting pipes and horn holes, applied in the field of pipe joints, can solve the problems of waste of pipes, high cost, disconnection of connecting pipes, etc., and achieve the effects of easy production, storage and transportation, reducing difficulty and cost, and avoiding truncation and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

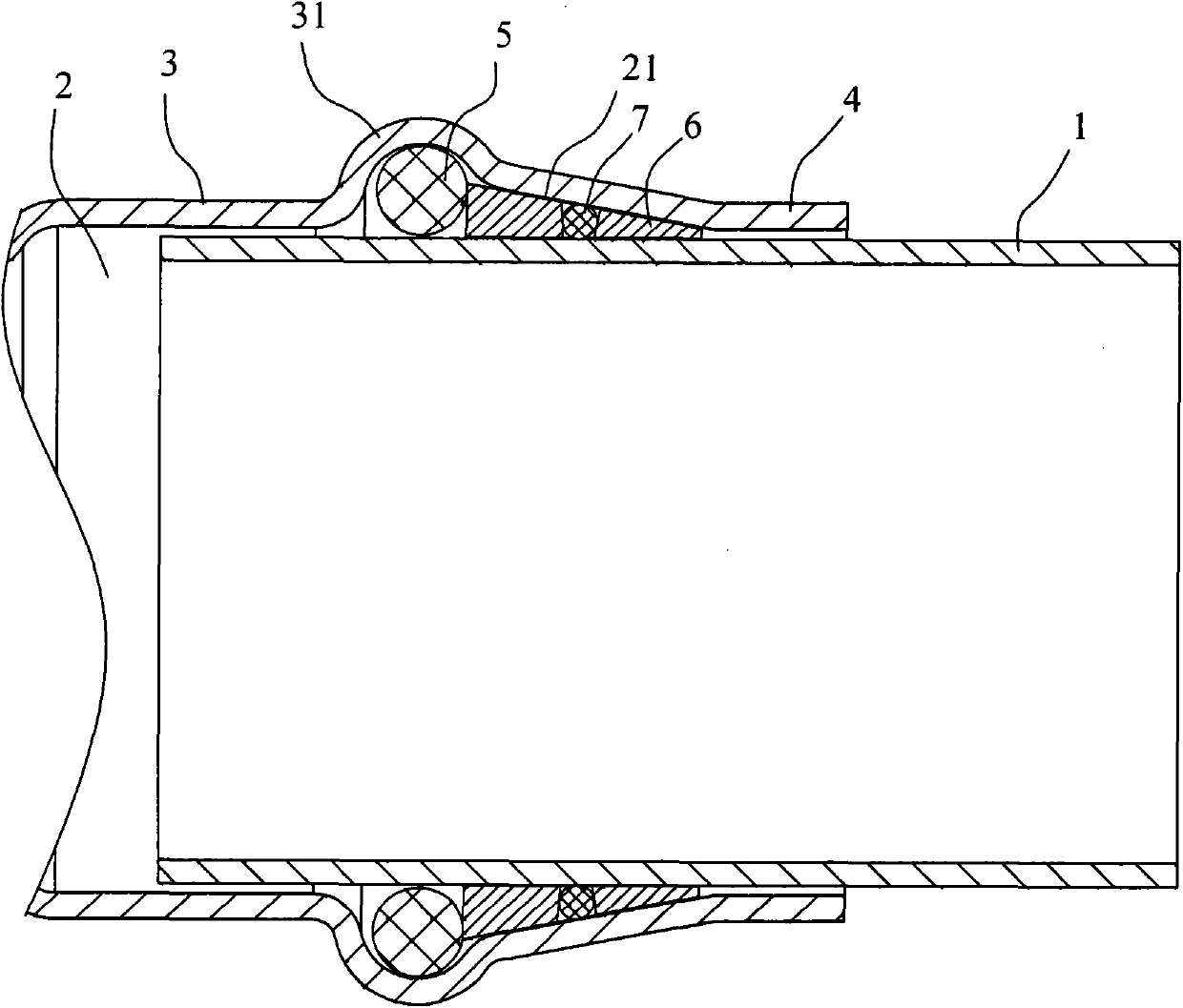

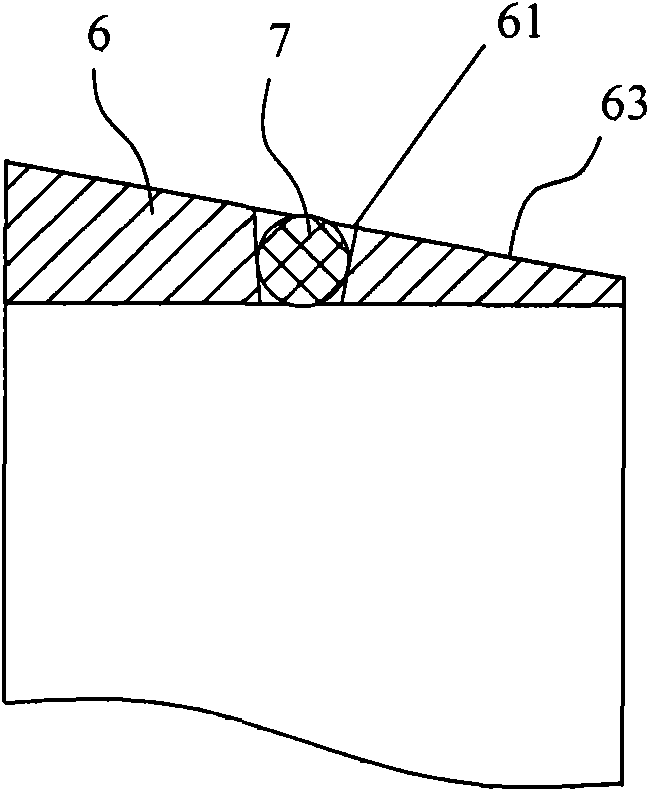

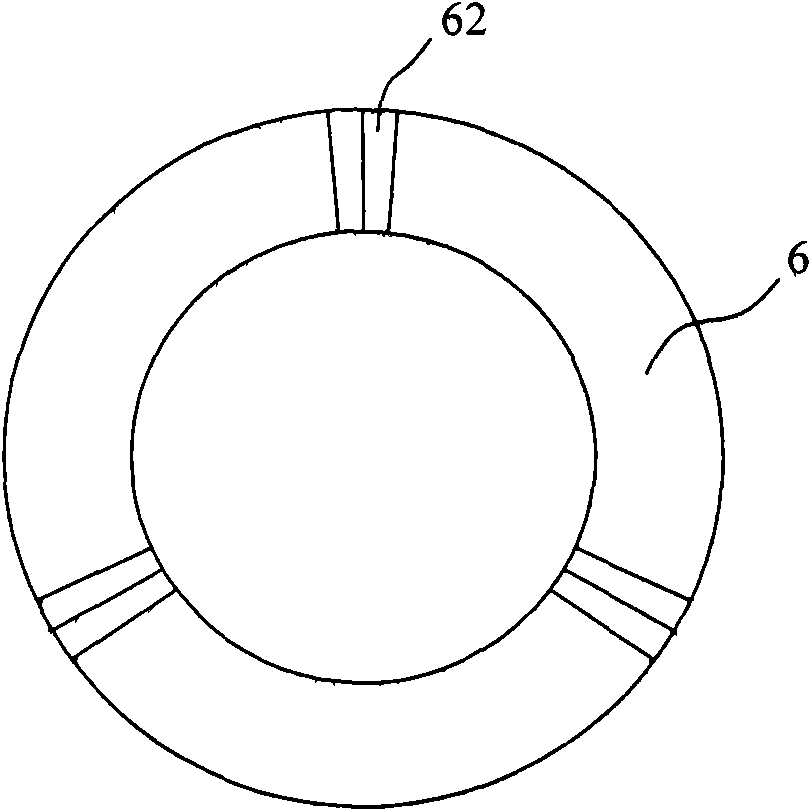

[0030] Such as figure 1 The shown direct push connecting pipe joint includes a joint body 3 having a through hole 2 for insertion of the connected pipe 1, a horn hole 21 is provided at the end of the through hole 2, and the big mouth of the horn hole 21 faces inward, and the horn hole The small mouth of 21 faces outward, and the joint body 3 wall between the small mouth of the horn hole 21 and the port of the through hole 2 is a sealing section 4, and a sealing rubber ring 5 is arranged in the big mouth of the horn hole 21, and a sealing rubber ring 5 is arranged in the small mouth of the horn hole 21. With locking parts. The locking part includes a support ring 6 and at least three balls 7 for being sleeved on the connected pipe 1. The inner end of the support ring 6 is pressed against the sealing rubber ring 5, and each ball 7 is rollingly installed on the support ring 6 Inside, and each ball 7 protrudes from the inner and outer peripheral surfaces of the supporting ring 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com