A safety protection device for a high-mixer

A technology for safety protection devices and high-mixing machines, which is applied in engineering safety devices, mixing machines, mechanical equipment, etc., can solve problems such as lack of protection, weak safety protection, and low reliability, so as to improve reliability and safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

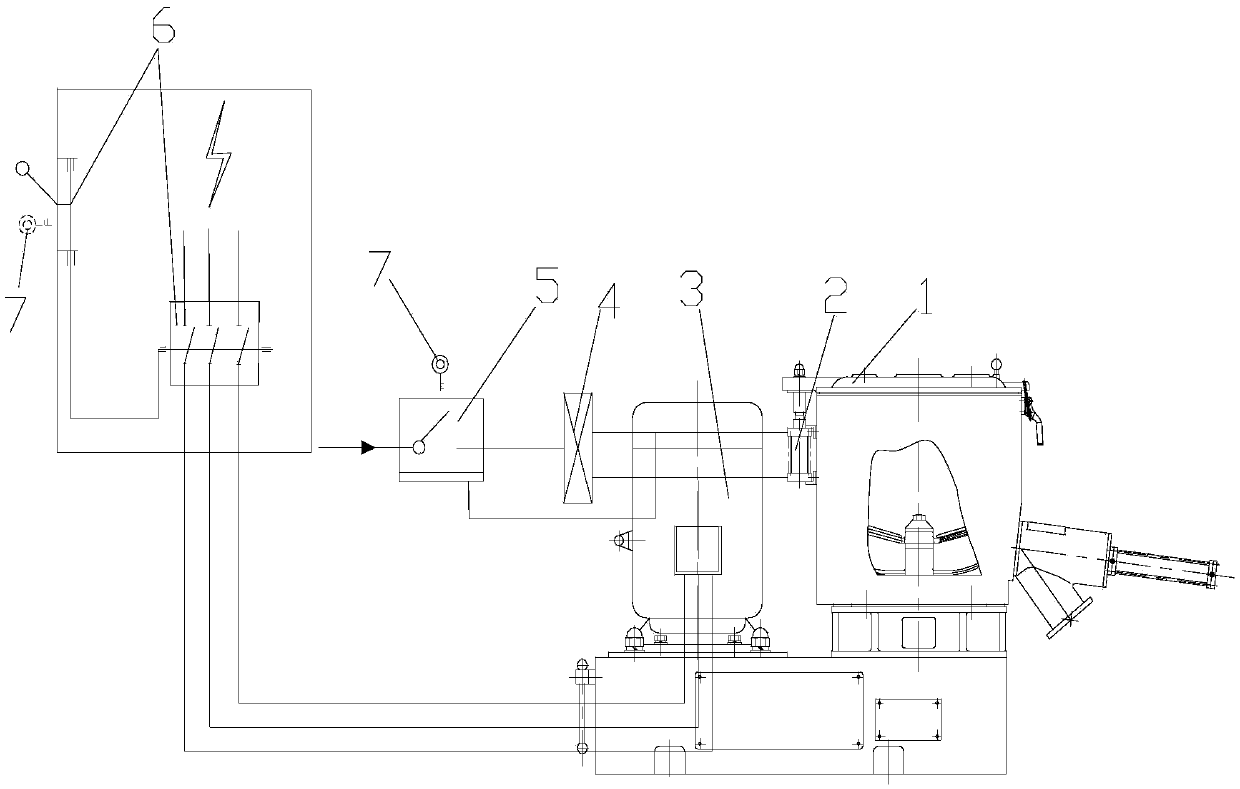

[0031] Such as figure 1 As shown in the safety protection device of a high-speed mixer, the high-speed mixer includes a cover 1, a cover opening cylinder for opening the cover 2, an air source matched with the cover opening cylinder, and a power motor 3 for providing power. The cylinder 2 is connected with a solenoid valve 4; the safety protection device includes a gas circuit lock mechanism 5, a circuit breaker lock mechanism 6 and an eccentric key 7, and the cover opening cylinder 2 and the solenoid valve 4 are both connected with the gas circuit lock mechanism 5; The circuit breaker lock mechanism 6 is serially connected to the power motor 3; the eccentric key 7 is alternately connected with the air circuit lock mechanism 5 and the circuit breaker lock mechanism 6 in cooperation.

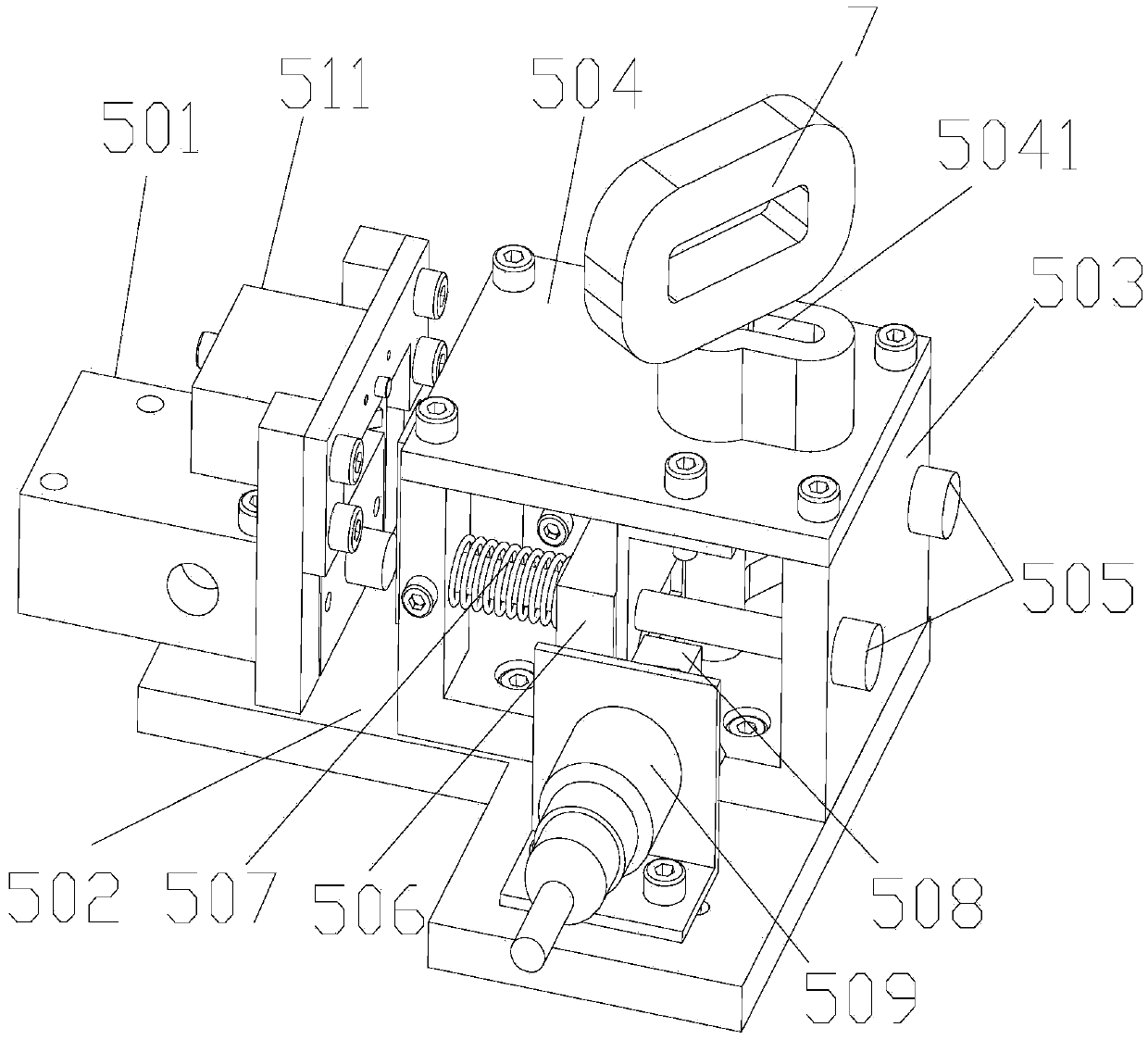

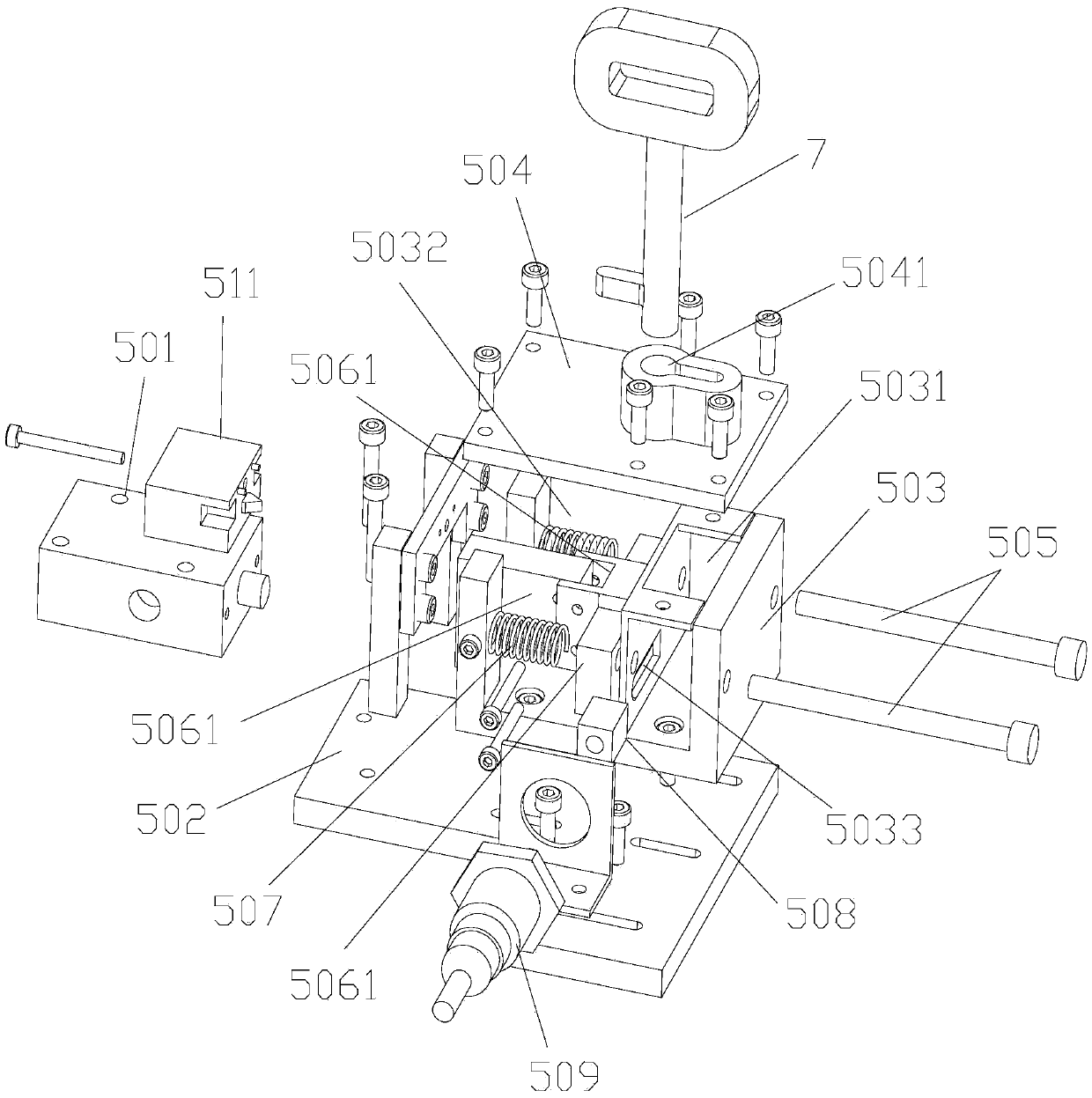

[0032] Specifically, the pneumatic lock mechanism 5 includes a mechanical valve 501, a base 502, a holder 503, a first cover 504, a first guide rod 505, a slider 506, a first spring 507, a stop 508, ...

Embodiment 2

[0044] The safety protection device of the high-speed mixer is the same as that of Embodiment 1 except for the following technical features: As a preference, the sliding block 506 includes a first sliding block 5061 and a second sliding block 5062, the first sliding block 5061 Both ends are provided with sliding holes through which the first guide rod 505 passes. The first sliding block 5061 and the second sliding block 5062 are integrally formed, and the first sliding block 5061 and the second sliding block 5062 are connected together. Type T. By adopting this design, it is very convenient to process the slider parts, and the processing cost is also reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com