Material storage and feeding method of screw forward and backward screw type biomass boiler

A technology of biomass boiler and feeding method, which is applied in the direction of combustion method, fuel supply, lump/powder supply/distribution, etc., and can solve the problems of continuous and controllable conveying of raw materials, steam pressure fluctuations, and inability to fill the warehouse, etc. , to achieve the effects of stable and reliable quantitative delivery, wide adaptability of raw materials, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

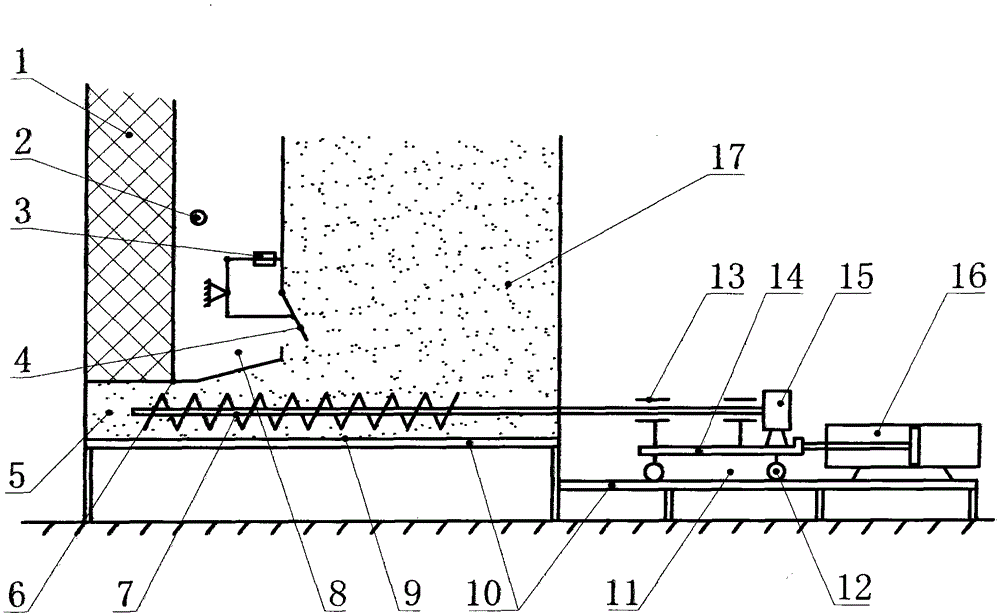

[0032] The present invention is to be connected by hydraulic oil cylinder 16 and screw rod mobile trolley 14, and screw rod mobile trolley 14 is done back and forth straight line running on trolley support positioning track 11, drives the conical screw rod 7 that is arranged on the bottom 9 of feed bin to do straight line forward and backward motion, and material Raw material 17 is pushed out of the raw material bin and transported to the boiler; the hydraulic motor 15 is connected to the conical screw 7 through the screw radial bearing 13 on the screw mobile trolley 14, so that the screw rotates, and when the conical screw 7 rotates, the screw moves back and resets. In preparation for advance during feeding, screw rotation alternates with linear motion and waits for a delay interval.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com