Standard Prestressing Apparatus for Verification of Residual Stress Indentation Test Method

A technology of loading device and testing method, which is applied in the direction of measuring device, measuring force, instrument, etc., can solve the problems of indirect measurement cumulative error, cannot directly provide accurate and reliable prestress value, etc., and achieve uniform stress state, good test conditions, Construct simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the pre-tensioning embodiment of the present invention will be described in detail with reference to the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

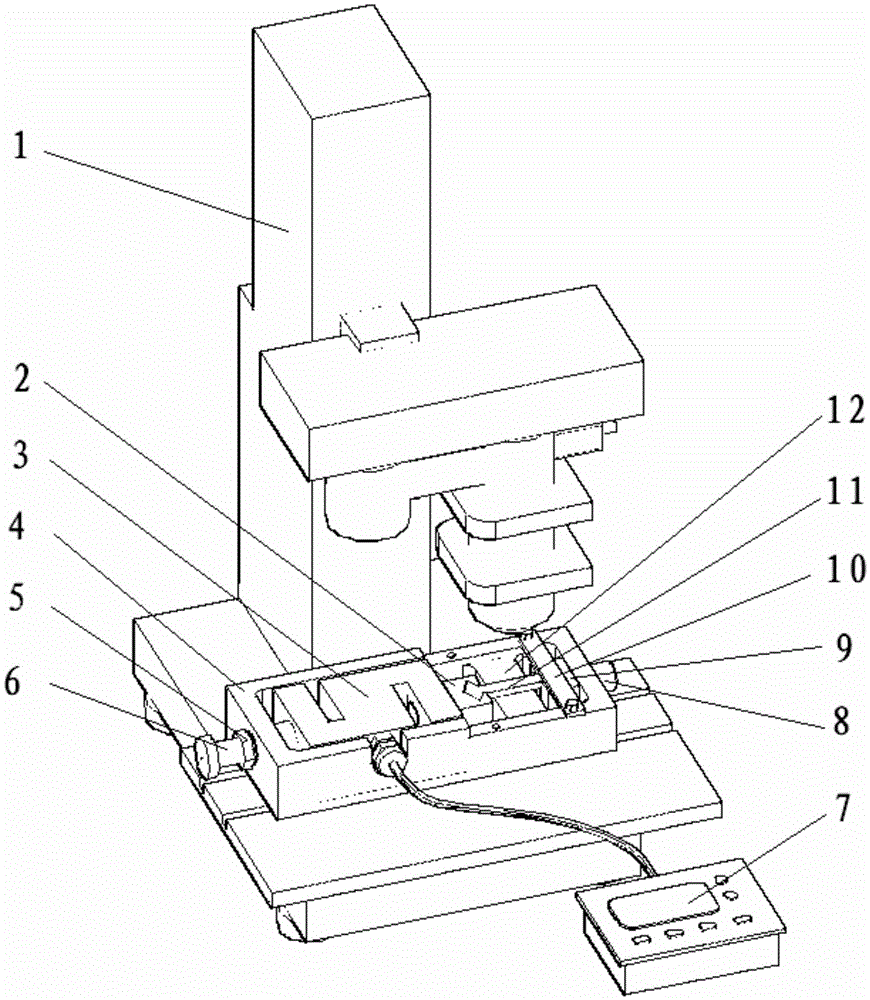

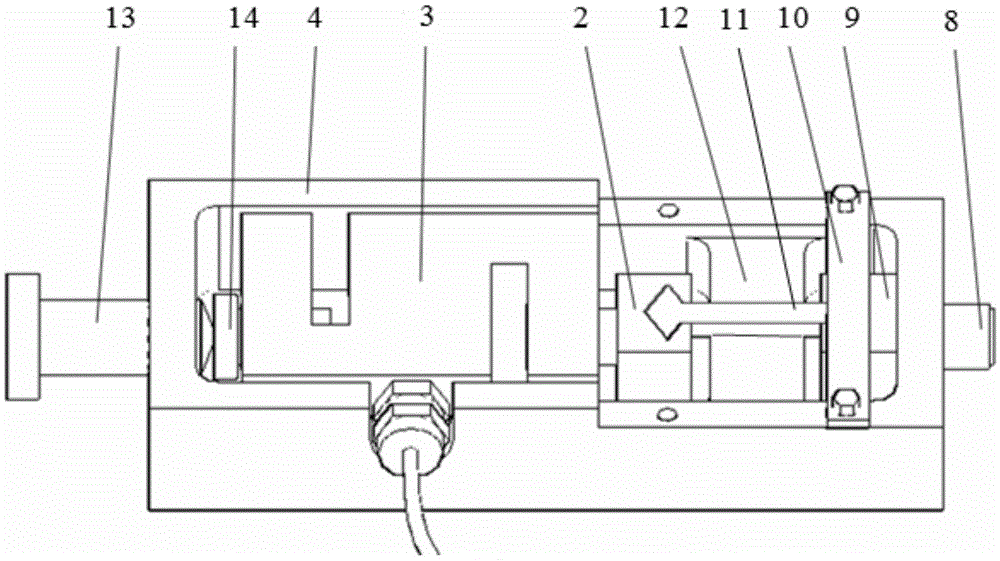

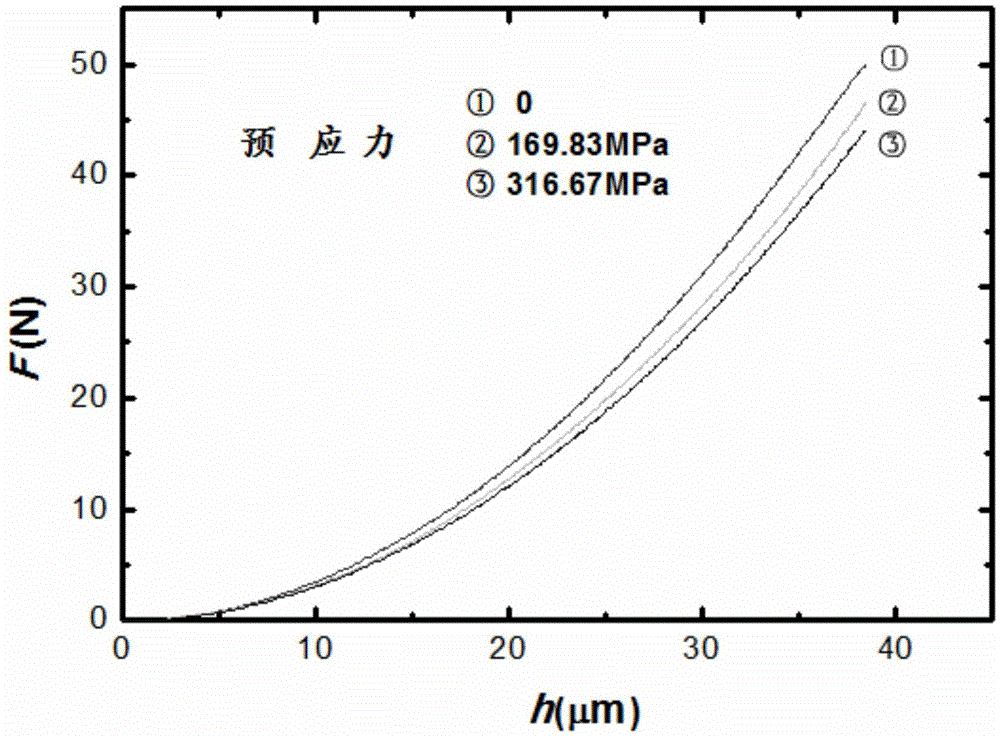

[0027] The present invention is a standard for the research of material residual stress indentation test method used in conjunction with a macro indenter (different from traditional hardness testers, which can obtain indentation load-depth (F-h) curves in real time) Prestressed loading experimental device. The device of the invention can generate ideal and uniform uniaxial tension (compression) prestress in the sample, and provide standard reference stress for the research of the residual stress intrusion test method.

[0028] Such as figure 1 As shown, the embodiment of the present invention is used with the Zwick indenter 1, which includes four parts: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com