Leading-in device for planar random residual stress

A technology of introducing device and residual stress, applied in the direction of measuring device, force/torque/work measuring instrument, force/torque/work measuring instrument calibration/test, etc. Perfect, the bending residual stress introduction device is not accurate enough, and the preparation is difficult to achieve the effect of simple structure, uniform stress state, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

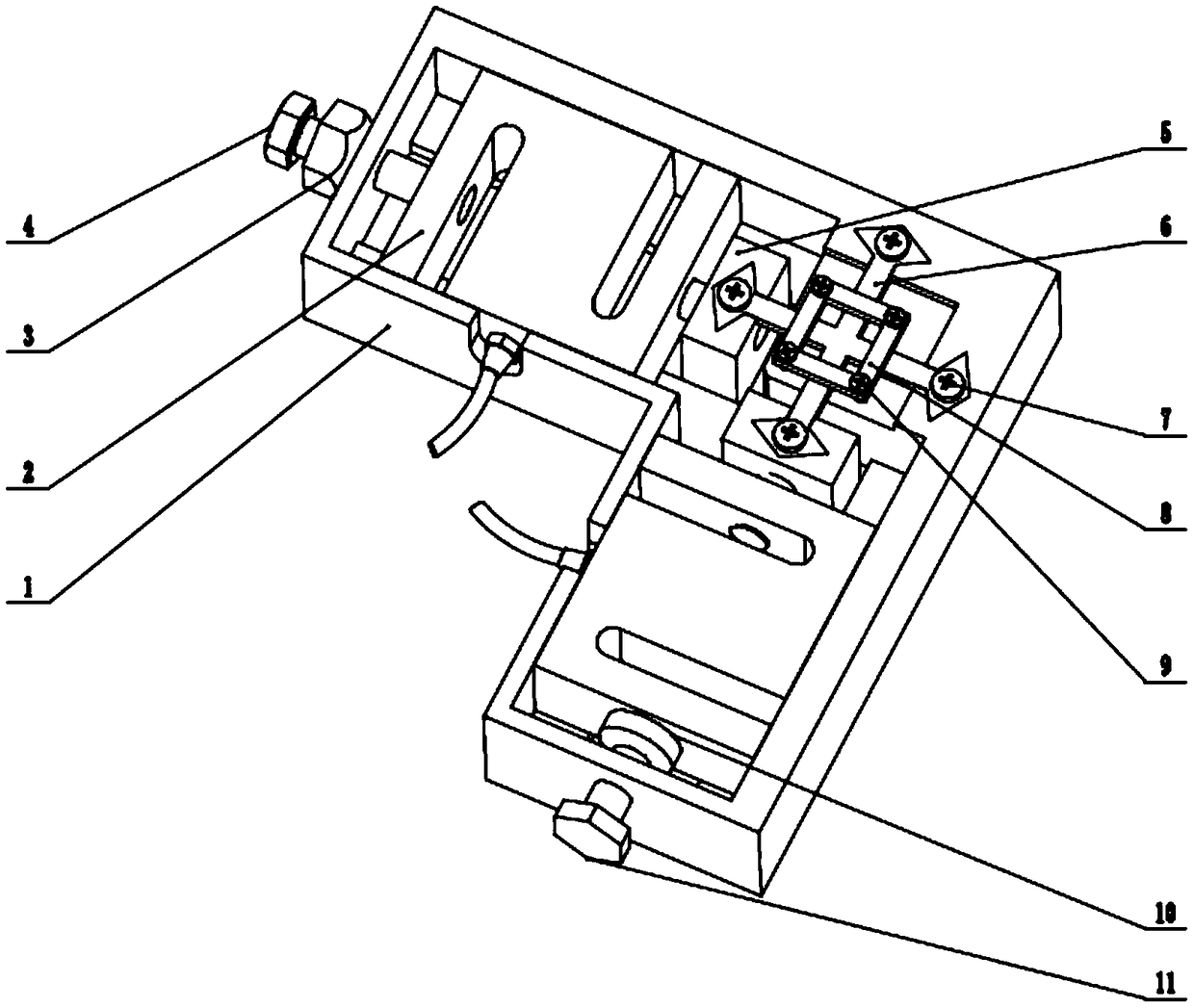

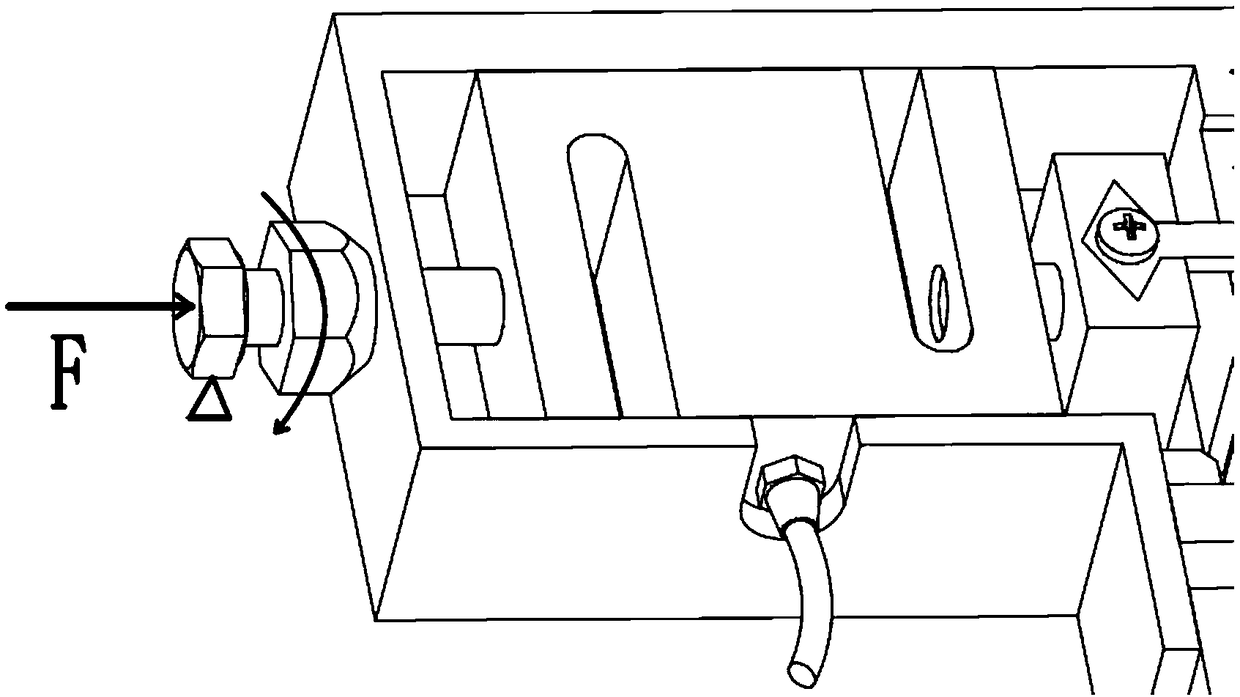

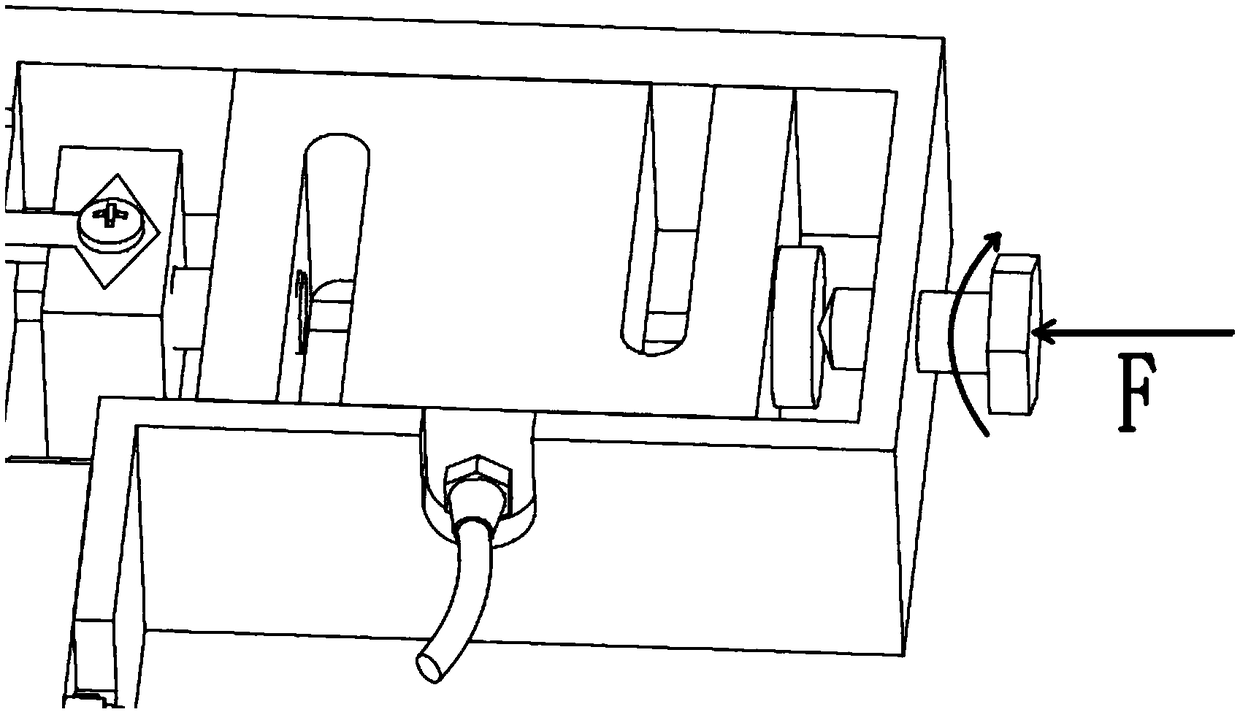

[0024] refer to Figure 1 to Figure 4 , a device for introducing arbitrary residual stress in a plane, including a base body 1, two sets of loading components, a load sensor 2, a movable fixture 5 and a pressing piece 8. The base body 1 is "L" shaped, with threaded through holes at both ends, a platform for supporting the sample 6, a diamond-shaped interface for fixing the sample 6, and a guide rail 12 for keeping the movable fixture 5 moving in parallel. The base body 1 is mainly used for installing and supporting accessories of various parts, and has a positioning function.

[0025] The loading assembly is connected to the load sensor 2 through a threaded through hole at one end of the base body 1 , and is used to apply transverse and longitudinal tensile stress and compressive stress to the test sample 6 .

[0026] The movable clamp 5 is located inside the base bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com