Large single magnetic sample making method for electrical steel magnetic property detection

A technology of electrical steel sheet and production method, which is applied in the direction of magnetic property measurement and hysteresis curve measurement, etc., can solve the problems of short service life, unsuitable long-term stability of monitoring and testing equipment, poor wear resistance of electrical steel surface coating, etc. Achieve long-term stability of magnetic properties, no component segregation, consistent metallographic structure and stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

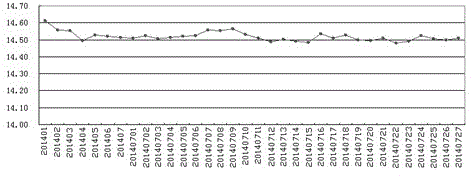

Image

Examples

Embodiment Construction

[0011] The method for making a large single-piece magnetic standard sample used in the detection of the magnetic properties of electrical steel sheets in the present invention adopts the finishing temperature of hot rolling at 910-920°C, the coiling temperature at 610-620°C and the annealing temperature after cold rolling at 810-820°C. ℃ smelting ultra-low-carbon rolled and chrome-plated steel coils with a carbon content of 0.0018%, trimming the rolled steel coils into long steel sheets, and dividing the long steel sheets into several square steel sheets to obtain Large monolithic magnetic standards produced in batches.

[0012] Further, both sides of the rolled steel coil are cut off by no less than 300 mm.

[0013] Further, the side length of the several square steel sheets is 500 mm.

[0014] Further, several square steel sheets are placed in an environment with a temperature difference of less than 1°C for more than 720 hours.

[0015] During the rolling process of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com