A hydraulic buffer device using shape memory alloy

A memory alloy and hydraulic buffer technology, applied in the direction of liquid shock absorbers, etc., can solve the problems of low utilization rate, difficult engineering practice, small buffer stroke, etc., and achieve the effect of high material utilization rate, simple stress state and improved displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions and with reference to the accompanying drawings.

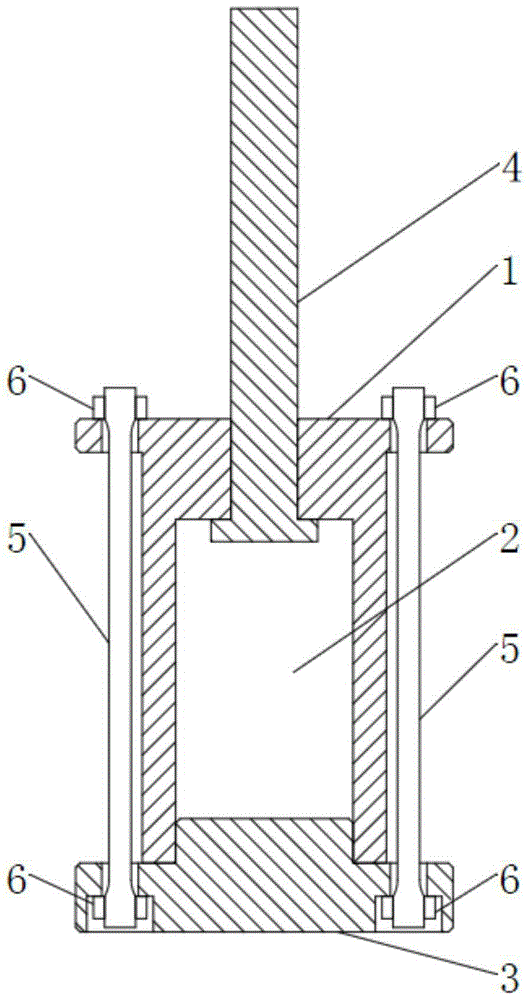

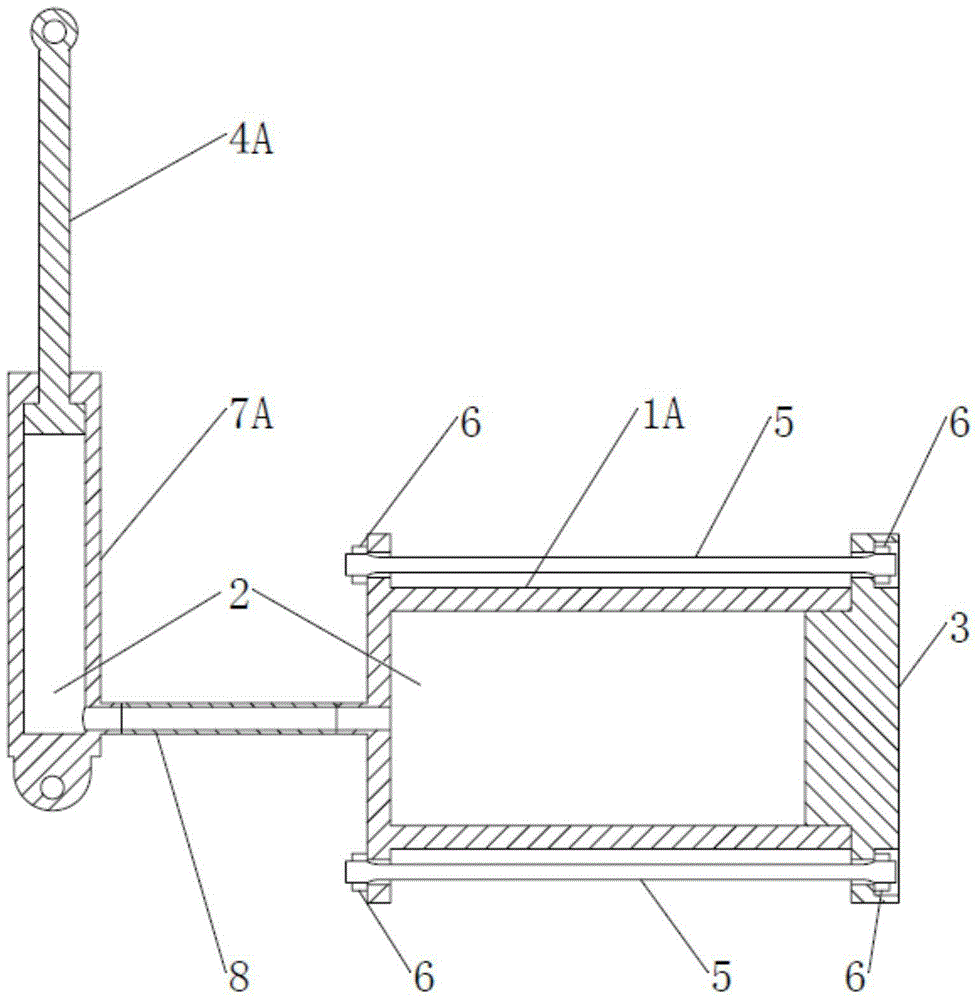

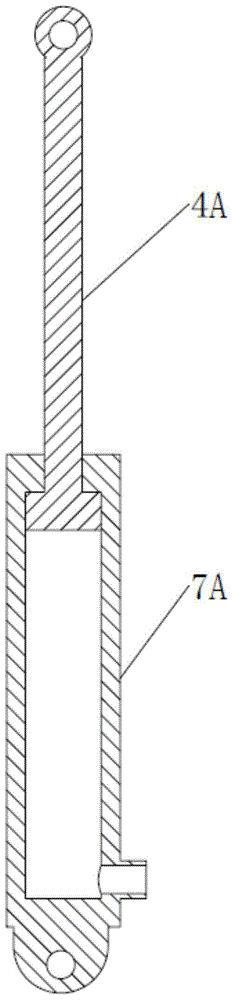

[0021] A basic model embodiment of the present invention, a hydraulic buffer device using shape memory alloy, such as figure 1 As shown, it includes hydraulic cylinder block 1, hydraulic oil 2, large piston 3, small plunger 4, shape memory alloy pull rod 5, fastening nut 6 and other components.

[0022] There is a sealing hole with a small area in the center of one end of the hydraulic cylinder 1, which is matched with the small plunger 4, and there are mounting holes symmetrically distributed around this end, and a sealing hole with a larger area at the other end, which is matched with the large piston 3. The area ratio of the large piston to the small plunger, that is, the area ratio of the large sealing hole to the small sealing hole is about 5 to 15 times. The edge of one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com