Systems and methods for producing silicon slim rods

A thin rod, cooling system technology, used in the field of silicon cutting systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

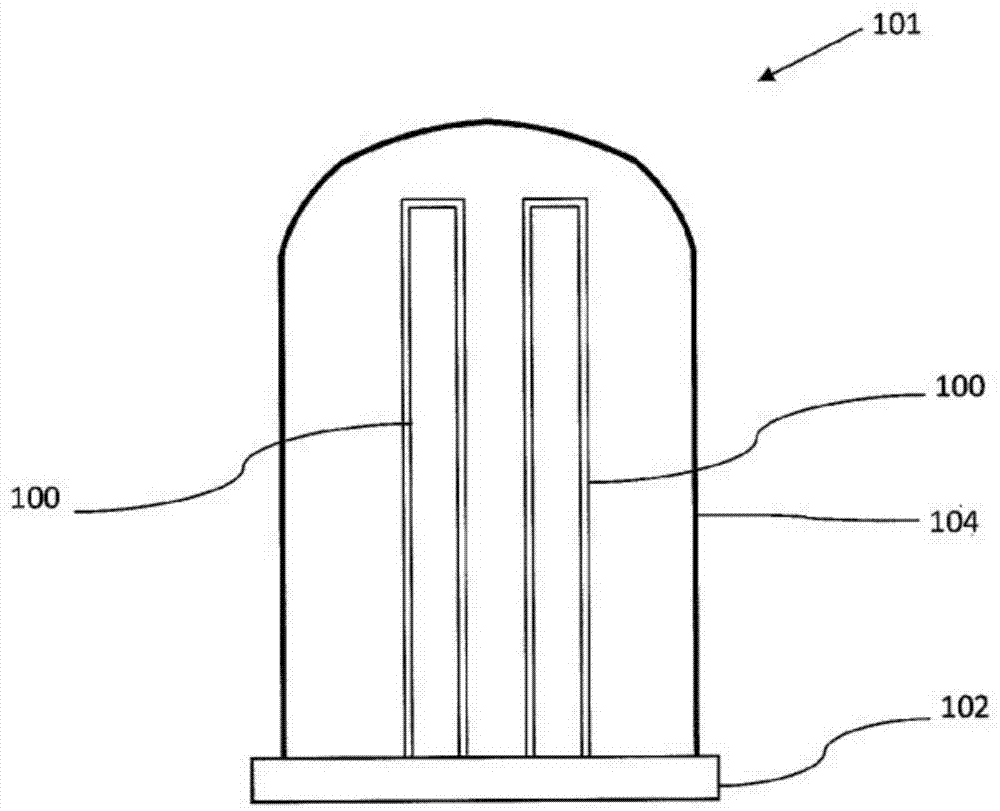

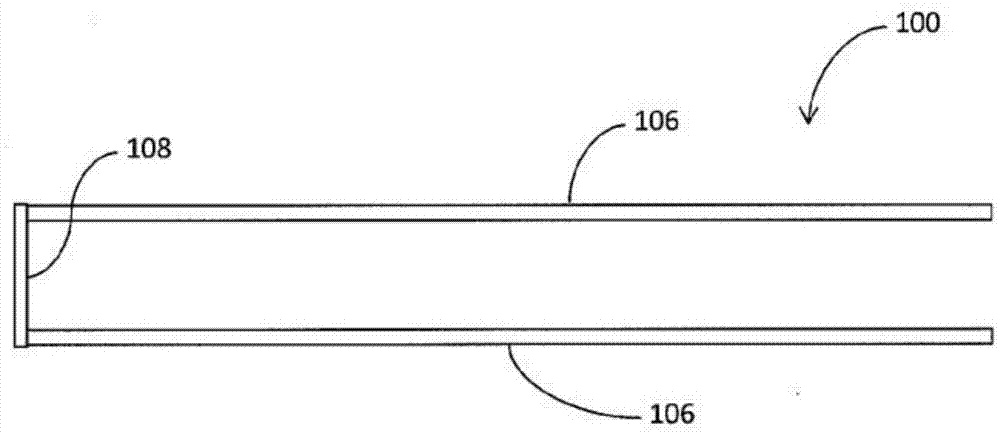

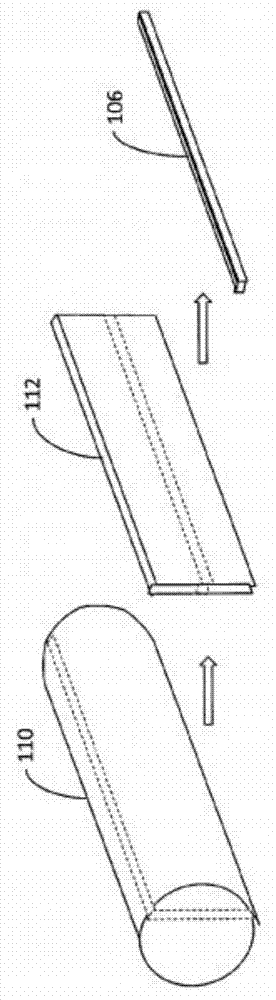

[0049] In general, the present application provides methods and systems for producing or preparing silicon thin rods. The present systems and methods involve processing polysilicon into ribbons (thin rods) from which filaments are composed. In one embodiment, an ingot of silicon is processed into a billet of appropriate thickness, which is then further processed into approximately square ribbons (thin rods) using one or more of the methods described below. These systems and methods can be broadly divided into cutting and lysing, both of which address zero or low kerf approaches. The described cutting methods aim to produce reduced kerfs and less breakage, resulting in higher material utilization. The described pyrolysis method can produce zero-width kerfs, resulting in even higher material utilization. The cracking method involves using a laser to create internal stresses in the material so that cracks propagate in a controlled manner. Cleavage can be performed by streaking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com