Dust collector

A technology for vacuum cleaners and suction ports, which is applied in the direction of vacuum cleaners, suction filters, cleaning equipment, etc. It can solve the problems that ordinary vacuum cleaners are difficult to meet the requirements of dust collection and purification, damage the health of operators, and inconvenience centralized dust collection. Portable and easy to move, outstanding filterability and air permeability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings.

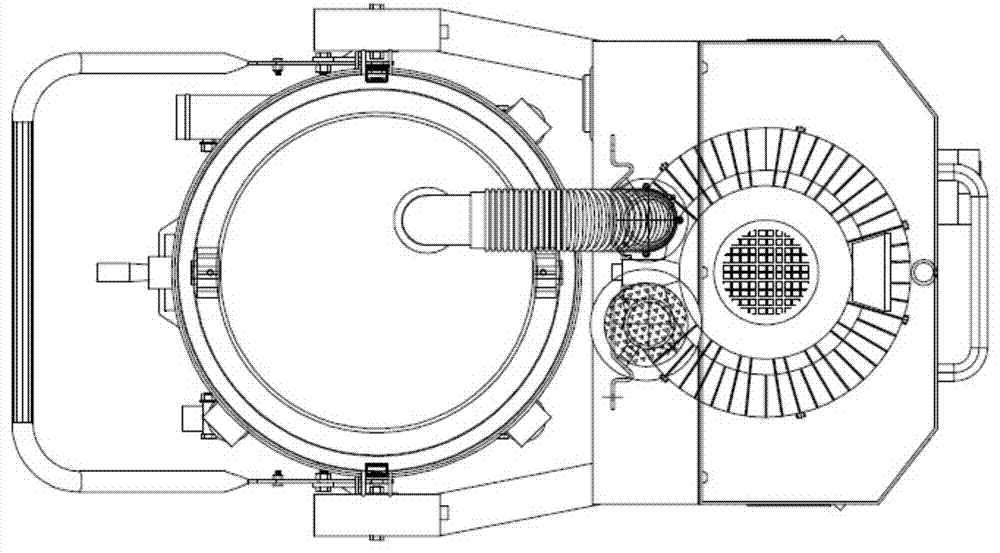

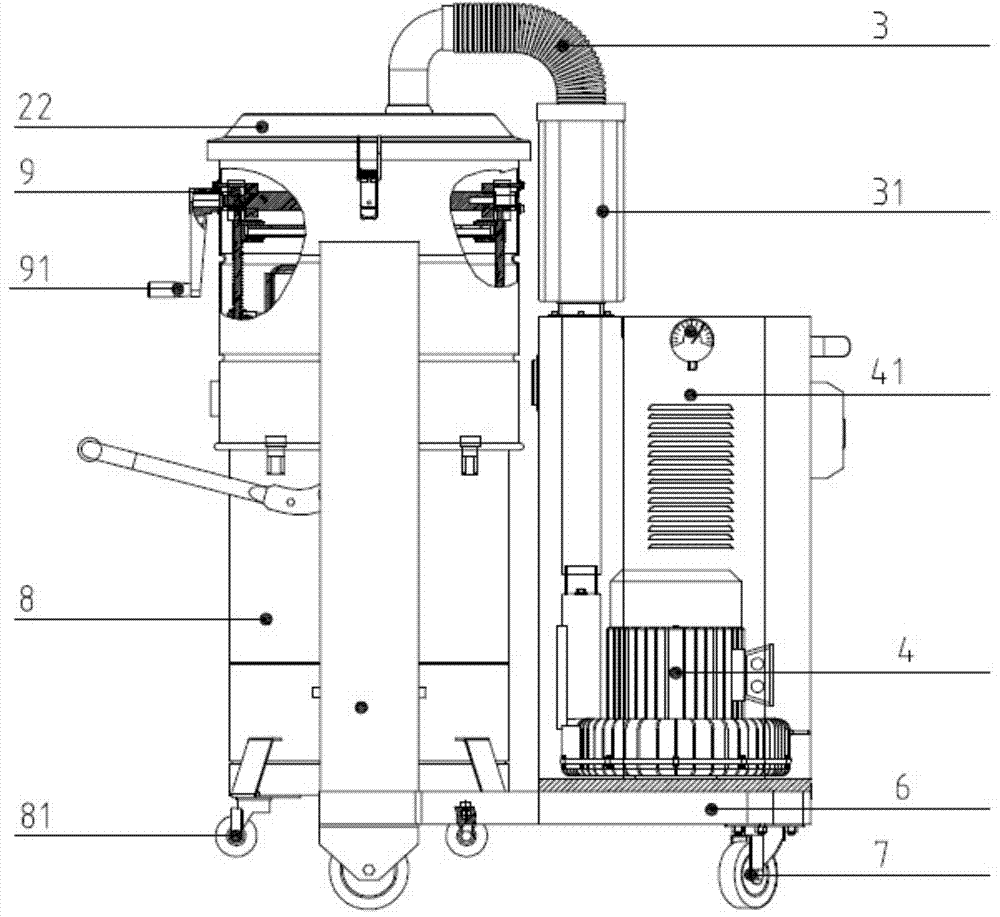

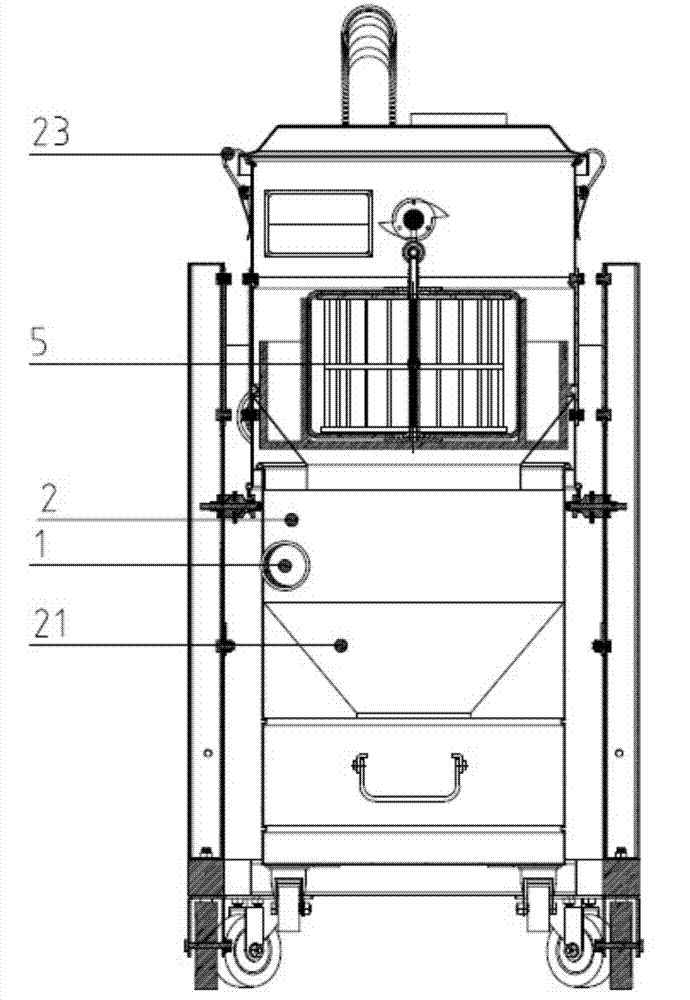

[0022] Such as Figure 1-3 As shown, a vacuum cleaner includes a tangential dust suction port 1, the tangential dust suction port 1 is arranged on the dust inlet box 2, and the lower part of the dust inlet box 2 is connected with a tapered separation cavity 21, The dust inlet box 2 is also communicated with the air exhaust port arranged on the fan 4 through the pipe 3, and the dust inlet box 2 is also provided with a filter for filtering the air flow from the dust suction port 1 and flows to the fan 4. Filters for the air outlet 5. An upper cover 22 is installed on the upper part of the dust inlet box 2 , and the upper cover 22 is connected with the dust inlet box 2 through a press button 23 , and the pipeline 3 is installed on the upper cover 22 . A muffler 31 is connected behind the exhaust port arranged on the fan 4 . The fan 4 is installed in the fan box 41, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com