Gravel bin of prefabricated fixed offshore platform

A fixed platform and gravel tank technology, applied in the field of prefabricated offshore fixed platforms, can solve the problems of slow gravel out of the tank, affecting the stability of the bottom, accumulation or dead angle, etc., and achieve the effect of good filling effect and fully uniform release range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

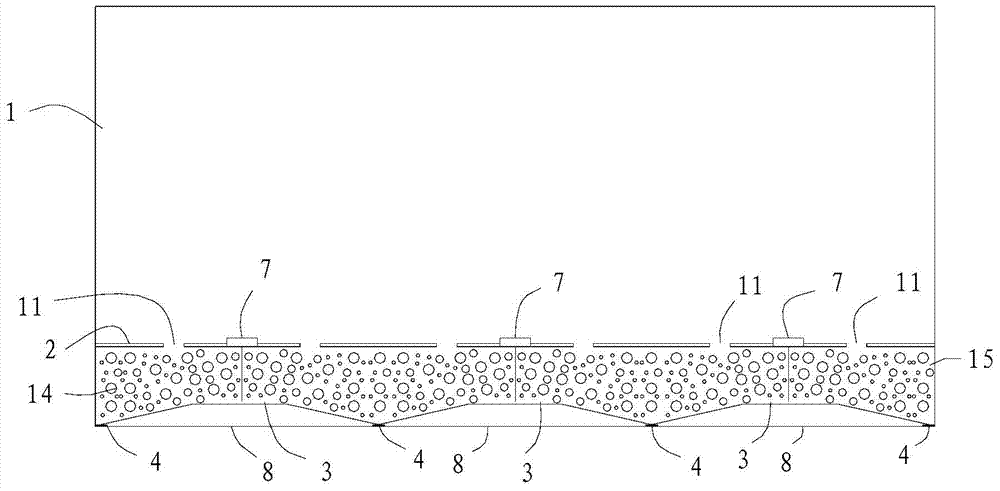

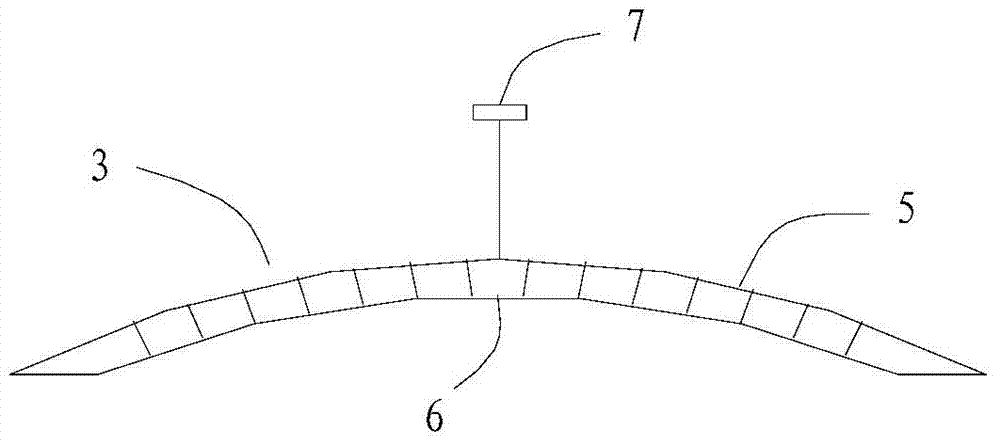

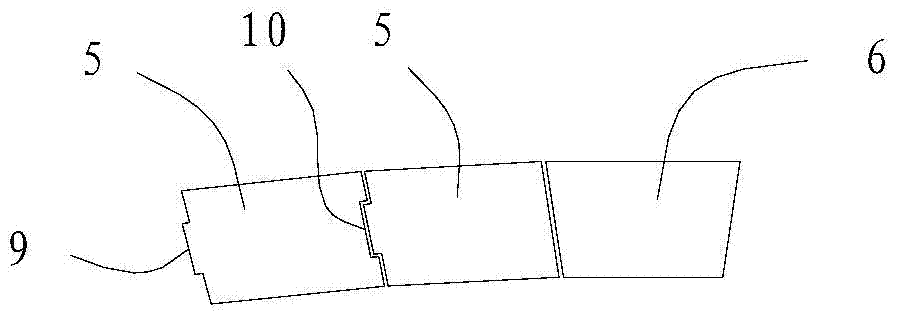

[0024] refer to Figure 1-3 , is a gravel tank of a prefabricated offshore fixed platform, used to store gravel 14 under the bottom plate 2 of the platform main body 1, which is surrounded by the bottom plate 2 and two arched decks 3, wherein the bottom plate 2 is respectively The arched deck supports 4 are set, and the ends of the arched decks 3 are respectively connected to the arched deck supports 4, and each arched deck 3 is in an upward arch shape, and is composed of block stones 5 and keystones 6 It is constructed by laying bricks and stones, and a keystone pulling and pressing device 7 is provided between the keystone 6 and the bottom plate 2 . A plurality of gravel replenishment holes 11 are provided on the bottom plate 2, and gravel can be replenished into the gravel chamber 15, and gravel can also be replenished to the filling surface after release. Prestressed tension beams 8 are arranged between two adjacent arched deck supports 4 , thereby forming a frame structu...

Embodiment 2

[0028] refer to Figure 4-5 , is another prefabricated gravel tank of a fixed offshore platform, which is used to store gravel 14 under the bottom plate 2 of the platform main body 1, which is surrounded by the bottom plate 2 and three arched decks 3, wherein the bottom plate 2 Arched deck supports 4 are provided, and the ends of the arched decks 3 are respectively connected to two adjacent arched deck supports 4. 5 and the keystone 6 are built together, and the keystone tension and compression device 7 is provided between the keystone 6 and the bottom plate 2. A plurality of gravel replenishment holes 11 are provided on the bottom plate 2, and gravel can be replenished into the gravel chamber 15, and gravel can also be replenished to the filling surface after release. The keystone 6 is tensioned upwards by the keystone pulling and pressing device 7 , so that both ends of the arched deck 3 press the arched deck support 4 . In addition, related restraint devices can be set be...

Embodiment 3

[0031] refer to Image 6 , is another prefabricated gravel tank of a fixed offshore platform, which is used to store gravel 14 under the bottom plate 2 of the platform main body 1, which is surrounded by the bottom plate 2 and a double-arched arched deck 3, wherein the bottom plate 2 is provided with an arched deck support 4 and a movable beam 12, and a beam tensioning and compressing device 13 is provided between the movable beam 12 and the bottom plate 2, and the movable beam 12 can be suspended below the bottom 2, and the arched deck 3 The ends are respectively connected to the arched deck support 4 and the movable beam 12, and the double arch is formed by the movable beam 12 and the two arched decks 3, and the tensile force is applied to the movable beam 12 through the beam tension and compression device 13 to ensure that the arch The structure of the arched deck is stable, and the bearing capacity is improved. At the same time, moving the movable beam 12 can also cause th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com