Automobile front buffering beam gauge

A front buffer and inspection tool technology, which is applied in the direction of measuring devices, instruments, and mechanical devices, can solve problems such as inconvenient operation, jamming, and troublesome inspection work, so as to avoid interference or jamming, simple inspection operation, and easy transportation. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

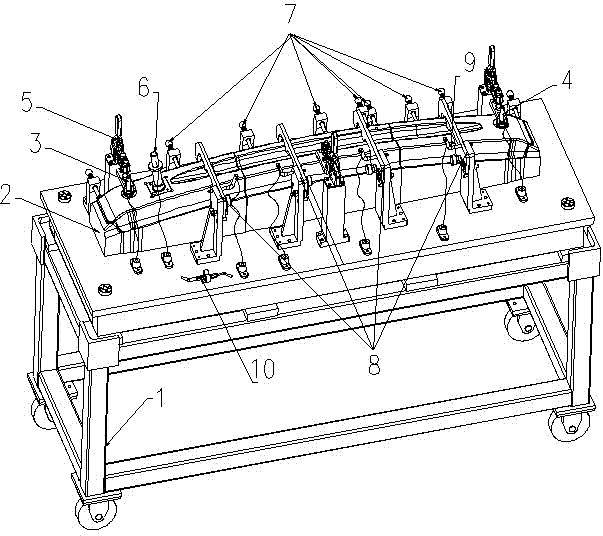

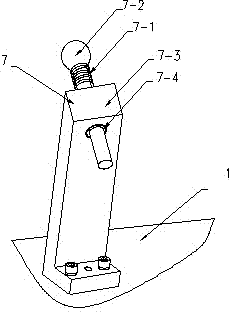

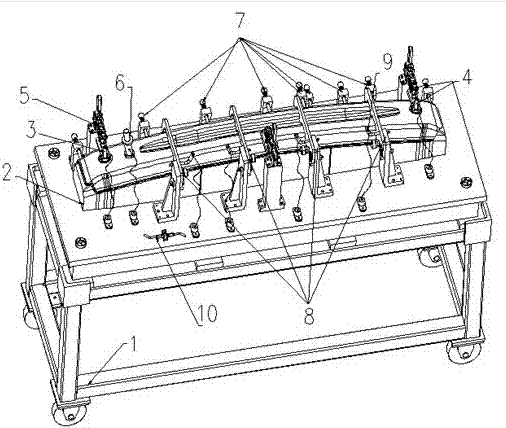

[0015] Depend on figure 1 As we know, the structural stereogram of the utility model is detected by the pulley base 1, the main positioning block 2 of the front buffer beam, the main positioning cone pin 3, the auxiliary positioning cone pin 4, the front buffer beam pressure clamp 5, and the tow hook hole of the front buffer beam Pin 6, front buffer beam wire harness hole position detection pin 7, front buffer beam profile detection block 8, belt tightening pin 9; front buffer beam main positioning block 2 is installed and fixed at the middle position of pulley base 1; front buffer beam The clamp 5 is installed on the front and rear sides of the main positioning block 2 of the front buffer beam through the connecting plate. The main positioning block 2 of the front buffer beam on the front and rear sides; the belt tightening pin 9 is used to fix the profile detection block 8 of the front buffer beam; the main positioning cone pin 3, the auxiliary positioning cone pin 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com