Pneumatic inward-clamped aero-engine rotor assembly method and device based on capacitance sensing measurement

An aero-engine and rotor assembly technology, applied in the field of mechanical assembly, can solve problems such as low coaxiality, and achieve the effects of reducing noise pollution, improving stability, and reducing CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

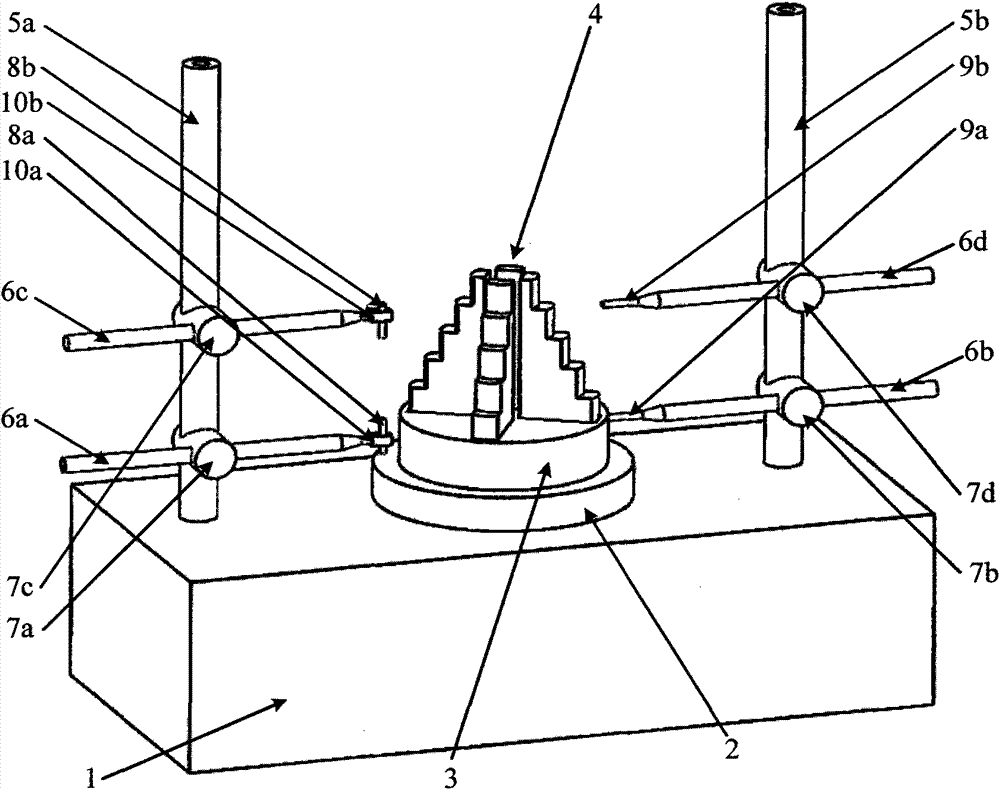

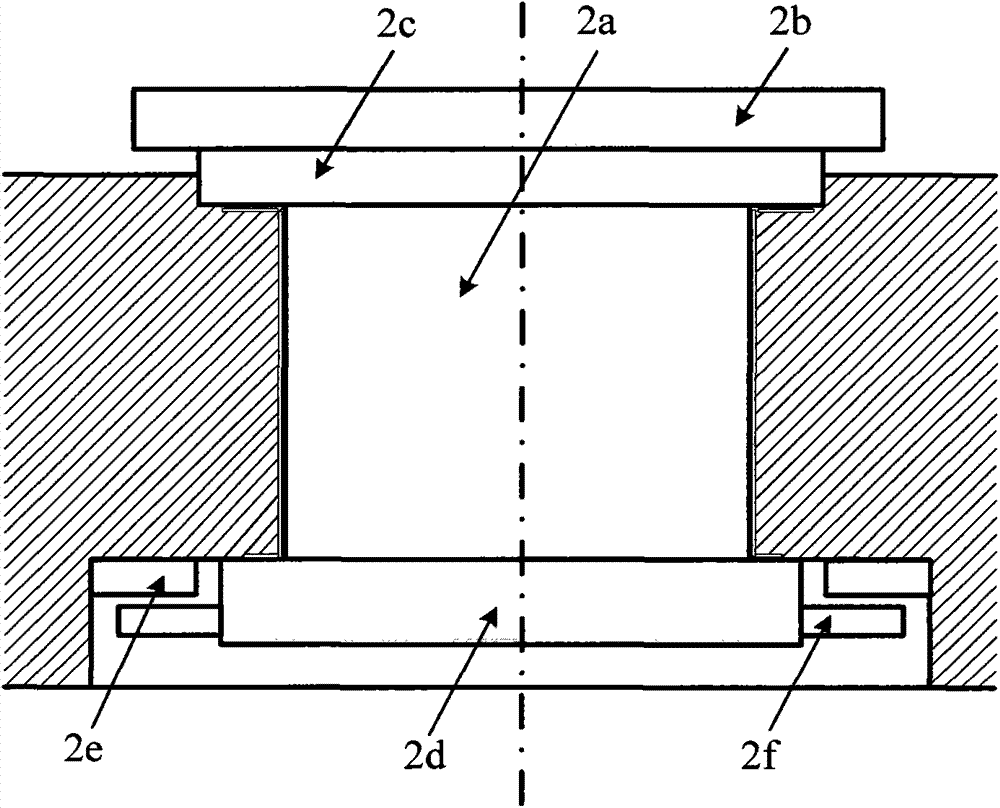

[0021] A method and device for assembling the rotor of an aerodynamic internal clamping aero-engine based on capacitive sensing measurement. The method and device are as follows: a four-jaw pneumatic chuck 4 is arranged on the center position of a centering and tilting workbench 3 . The left column 5 a and the right column 5 b are symmetrically distributed on both sides of the air bearing shafting 2 and fixed on the base 1 . On the left column 5a, the left upper column connecting piece 7c and the left lower column connecting piece 7a are movably adjusted sequentially from top to bottom, and the left upper horizontal measuring rod 6c is horizontally nested on the left upper column connecting piece 7c, and the upper sensor is transferred The piece 10b is fixedly connected with the upper left horizontal measuring rod 6c, and the upper axial capacitive sensor 8b is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com