Disassembling tool for hub of bulldozer

A technology for dismantling tools and bulldozers, applied in the directions of manufacturing tools, wheel assembly and disassembly equipment, wheels, etc., can solve problems such as difficulty in disassembly, and achieve the effect of rapid disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

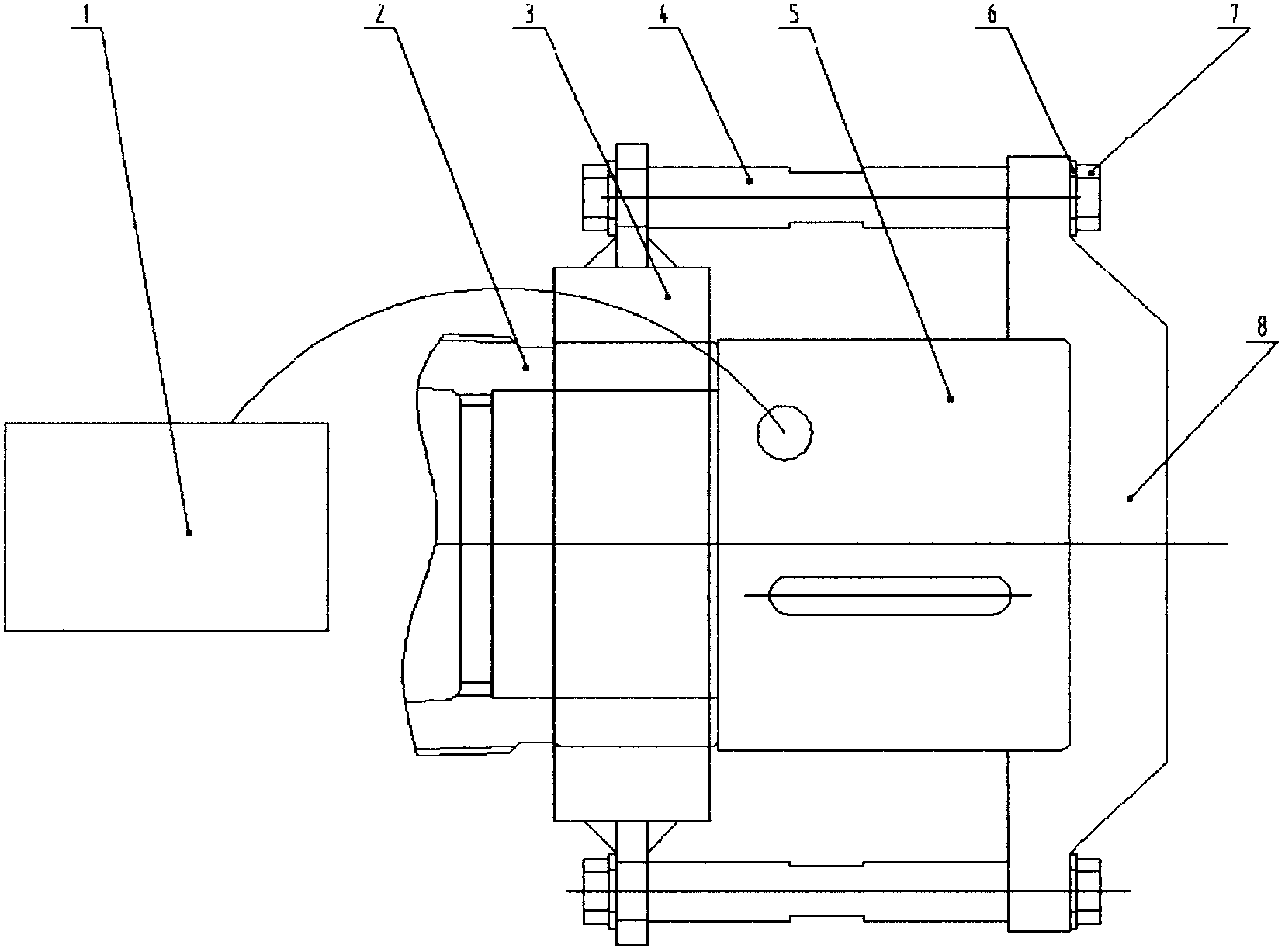

[0008] The content of the technical solution is described in detail in conjunction with the accompanying drawings.

[0009] Assembly and working order: Connect the internal thread of the connecting plate 3 with the external thread of the hub 2, seat the jack 5 in the base 8 (the base 8 is a concave-shaped original tray with 2 holes on it), and pass 2 pull rods 4 (the pull rods 4 is cylindrical, there are two milled planes in the middle, the purpose is to use a wrench during installation to avoid slipping, and both ends have internal threads), connect the base 8, the jack 5 and the connecting plate 3, and tighten them with the washer 6 and the bolt 7 Fixed, so that the connecting disc 3, the wheel hub 2, the base 8, and the pull rod 4 have become a whole. Then turn on the manual hydraulic station 1 to press the jack 5. The piston part of the jack 5 starts to work and slowly stretches out. When it contacts the hub 2, continue to press the jack 5. Using the principle of action fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com