Cavity plate positioning mechanism

A technology of positioning mechanism and master template, which is applied in the field of positioning mechanism, can solve problems such as failure to work, material head stuck, spring back of the master template, etc., to achieve the effect of convenient removal and full-automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

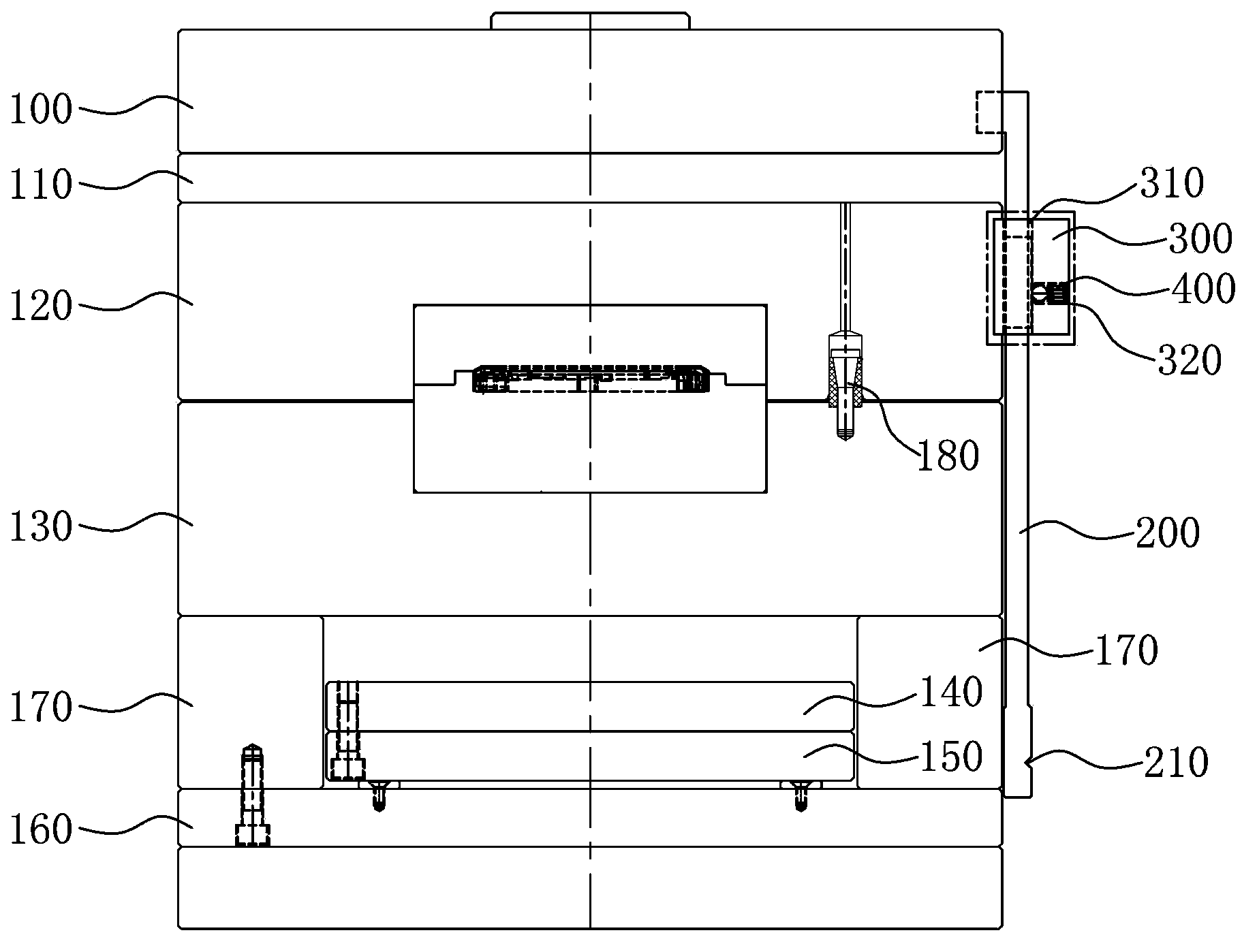

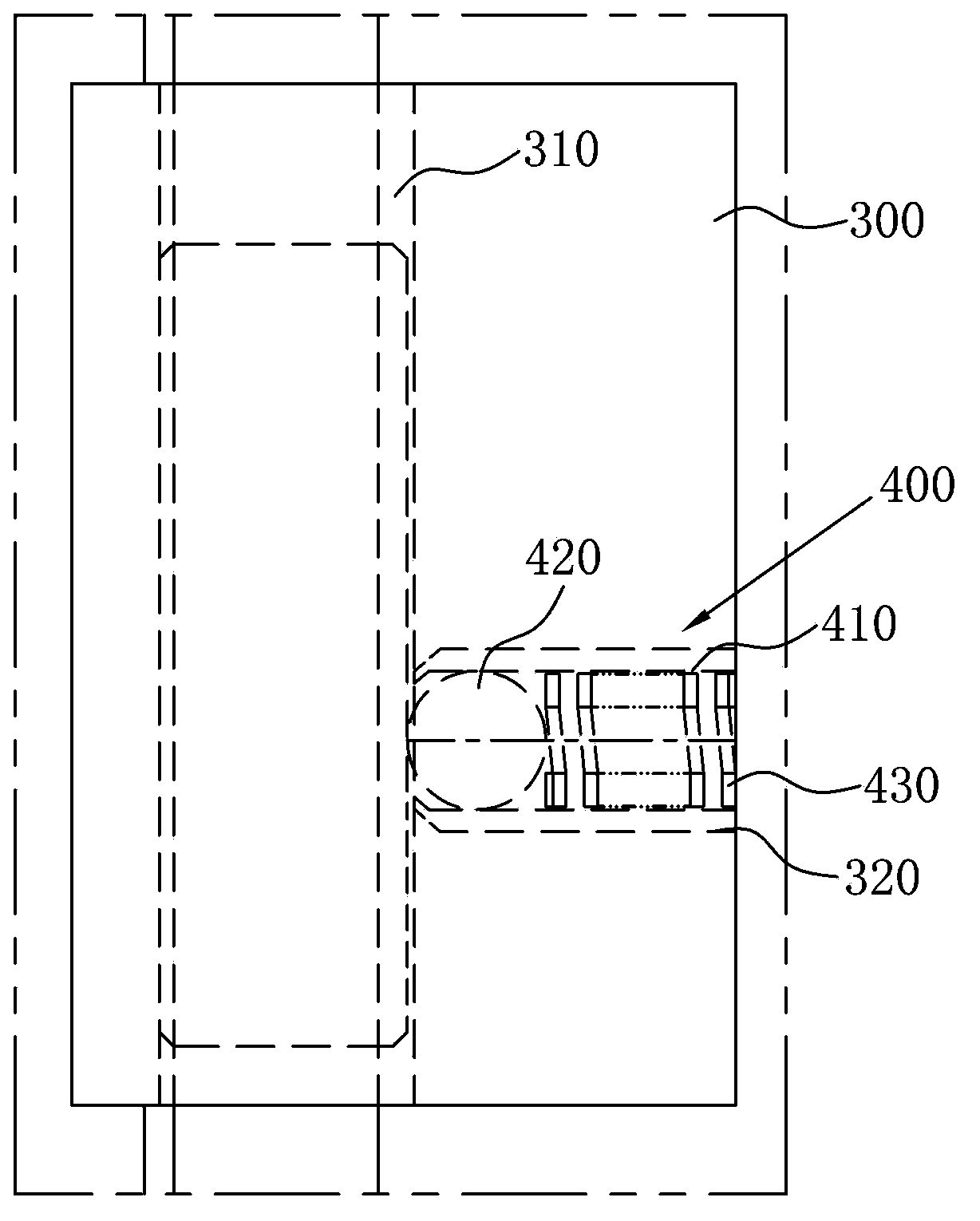

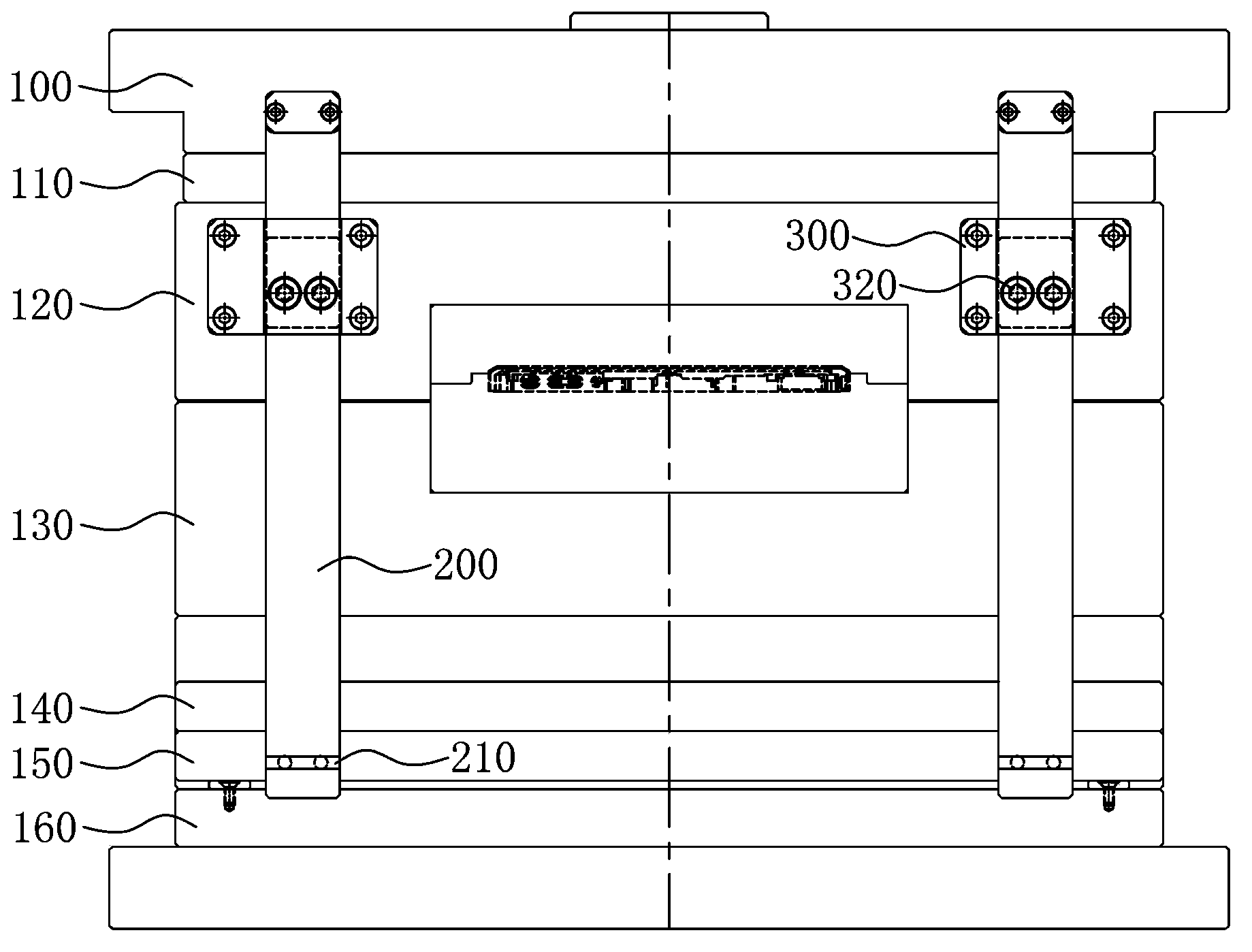

[0026] Please refer to figure 1 , figure 2 and image 3 shown, where figure 1 A schematic diagram showing an angle of the positioning mechanism of the master template of the present invention in the mold clamping state, figure 2 painted figure 1 The partial enlarged schematic diagram of the image 3 It shows another perspective schematic view of the positioning mechanism of the master template of the present invention in the state of mold clamping.

[0027] The female template positioning mechanism of the present invention is applied to a three-plate mold, and the three-plate mold includes: an upper fixing plate 100, a stripping plate 110, a female template 120, a male template 130, an upper ejector plate 140, and a lower ejector plate 150 , the lower fixed plate 160 and the two-foot pad 170 between the male template 130 and the lower fixed plate 160, take the mold opening direction as the vertical direction, in this embodiment, the female template positioning mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com