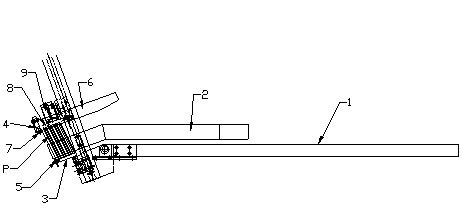

Sheet blank feeding mechanism

A feeding mechanism and billet technology, which is applied in the direction of thin material processing, supplying workbench, pile separation, etc., can solve the problems affecting the reliability, affecting the reliability of the feeding mechanism, the inconvenience of installation and debugging, etc., and achieve the goal of reliable discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

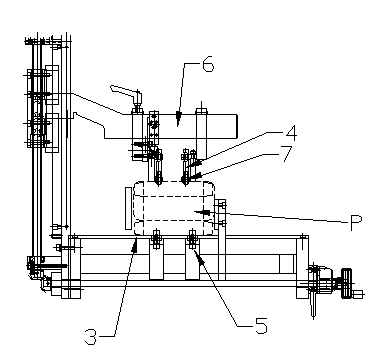

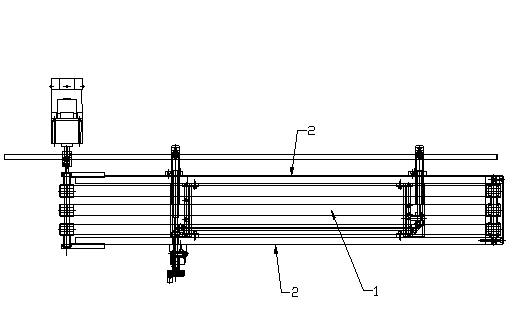

[0012] As shown in the figure, the sheet blank feeding mechanism includes a set of conveying belts 1 driven horizontally by power, and the sheet blanks arranged in a vertical state can be forwarded by it on the conveying belt; Side plates 2 are set on both sides of the material belt to limit and guide the two sides of the billet. The front end of the conveyor belt is provided with a discharge plate 3 connected with the conveyor belt. The front end of the discharge plate is provided with a pair of blockable sheet blanks. The upper stop card 4 and the lower stop card 5 of the upper and lower edges of P; the discharge plate 3 is inclined downward at a certain angle. The upper stop card 4 is installed on an adjustable frame 6 that can move up and down. The adjusting frame 6 is driven by a screw nut mechanism to lift it. A roller 7 is provided at the part where the lower end of the upper stop card 4 contacts with the upper edge of the sheet blank, so that the discharge is smoother...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap