Porous composite sialon ceramic and preparation method for same

A technology of composite ceramics and sialon, which is applied in the direction of ceramic products, other household utensils, household utensils, etc., can solve the problems of high production costs, achieve the effects of reducing preparation costs, wide sources, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

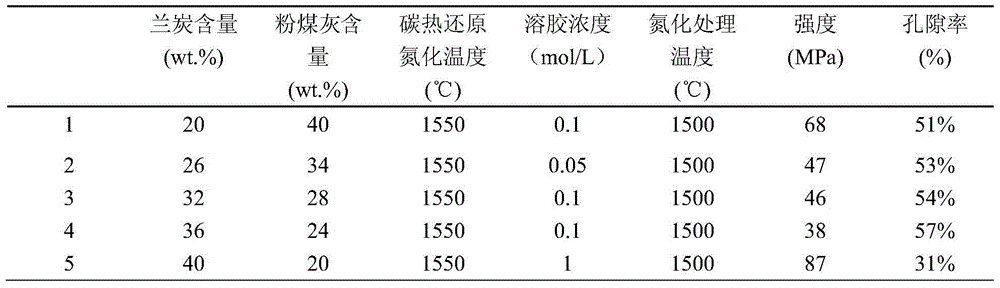

Examples

preparation example Construction

[0031] The preparation method of the porous sialon composite ceramics provided by the present invention is implemented according to the following steps:

[0032] a: First, weigh 20% to 45% of semi-coke powder, 10% to 30% of fly ash powder, 5% to 25% of alumina powder, and 2% to 8% of nitriding powder according to the following mass percentages. Aluminum powder, 5% to 25% silicon powder, 3% to 12% binder and 5% to 20% inorganic sol, and then use absolute ethanol as a dispersant to mix blue carbon powder, fly ash powder, oxidation Aluminum powder, aluminum nitride powder and silicon powder are prepared into mixed powder by wet ball milling process, and then the mixed powder is dried, added to the binder completely dissolved in absolute ethanol, and stirred evenly to form granular raw materials;

[0033] b: Put the granular raw material obtained in step a into the mold cavity, press molding, and dry and solidify the pressed green body at 80°C to 120°C;

[0034] c: placing the gr...

Embodiment 1

[0046] Weigh the semi-coke powder with an average particle size of 10 μm and a carbon content of 87%, the fly ash powder with an average particle size of 10 μm and an alumina content of 25% and a silicon oxide content of 45%, and the carbon dioxide powder with an average particle size of 5 μm. Aluminum powder, aluminum nitride powder with an average particle size of 5 μm, silicon powder with an average particle size of 40 μm, phenolic resin, and alumina sol with a concentration of 0.05 mol / L, blue carbon powder accounts for 20% of the total mass, Fly ash powder accounts for 30%, alumina powder accounts for 5%, aluminum nitride powder accounts for 8%, silicon powder accounts for 25%, phenolic resin accounts for 3%, and alumina sol accounts for 9%. Then use absolute ethanol as a dispersant to prepare a mixed powder from semi-coke powder, fly ash powder, aluminum oxide powder, aluminum nitride powder and silicon powder through a wet ball milling process, then dry the mixed powder ...

Embodiment 2

[0049] Weigh the semi-coal powder with an average particle size of 20 μm and a carbon content of 90%, the fly ash powder with an average particle size of 60 μm, an alumina content of 26% and a silicon oxide content of 46%, and an oxide powder with an average particle size of 40 μm. Aluminum powder, aluminum nitride powder with an average particle size of 40 μm, silicon powder with an average particle size of 20 μm, PVB, and a mixture of alumina sol and silica sol (or silica sol and titanium oxide sol) with a concentration of 0.7 mol / L mixture, or alumina sol and titania sol mixture), in the total mass, blue carbon powder accounts for 45%, fly ash powder accounts for 10%, alumina powder accounts for 21%, aluminum nitride powder accounts for 2%, silicon powder It accounts for 5%, PVB accounts for 12%, and the mixture of alumina sol and silica sol accounts for 5%. Then use absolute ethanol as a dispersant to prepare a mixed powder from semi-coke powder, fly ash powder, aluminum o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com