Method for preparing reinforced aerogel

An aerogel and strong technology, which is used in the field of preparing strong aerogels, can solve problems such as cracking and large shrinkage, and achieve the effect of strengthening the gel skeleton, enhancing the strength and realizing the strengthening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

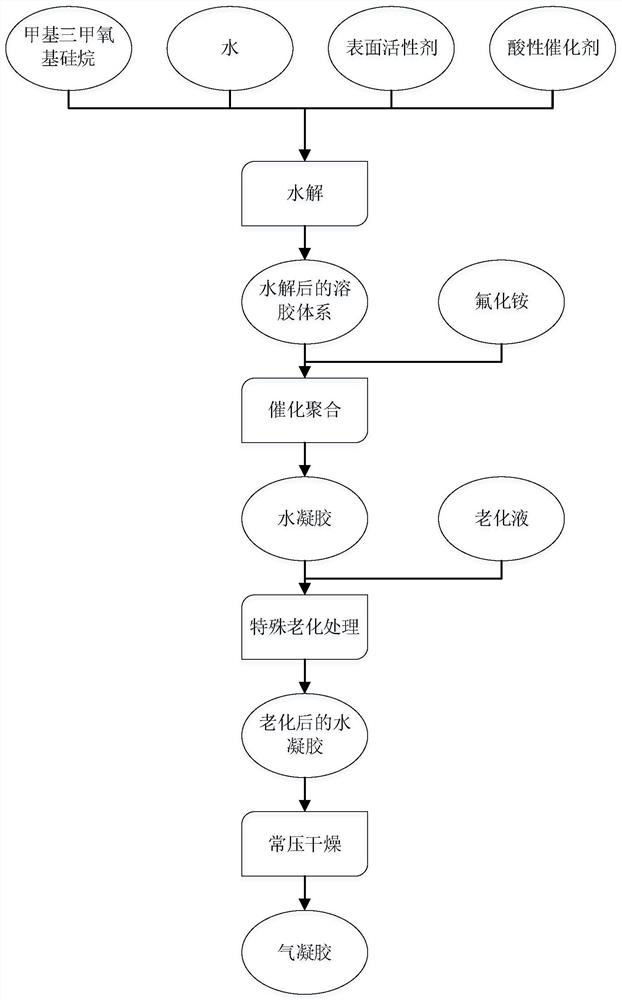

Image

Examples

Embodiment 1

[0022] Weigh 120 parts by mass of solvent water, add 0.1 parts by mass of acetic acid, then add 2.0 parts by mass of surfactant cetyltrimethylammonium chloride, stir well and add 100 parts by mass of precursor methyl trimethoxy base silane was stirred for hydrolysis.

[0023] The hydrolysis temperature is 20° C., and the hydrolysis time is 1 hour.

[0024] After hydrolysis, 0.003 parts by mass of ammonium fluoride was added and stirred at a temperature of 20° C., and then polymerized.

[0025] The polymerized hydrogel is subjected to aging treatment, the concentration of ammonium fluoride in the aging solution is 0.5M, and the volume ratio of the aging solution to the gel is 3:1;

[0026] The aging temperature is 90° C., and the aging time is 72 hours.

[0027] Dry the aged hydrogel under normal pressure. The drying process is 30°C for 3 hours, 60°C for 3 hours, 90°C for 3 hours, and 120°C for 3 hours to obtain high-strength airgel.

Embodiment 2

[0029] Weigh 100 mass parts of solvent water, add 0 mass parts of acetic acid, then add 1.5 mass parts of surfactant cetyltrimethylammonium chloride, stir well and add 90 mass parts of precursor methyl trimethoxy base silane was stirred for hydrolysis.

[0030] The hydrolysis temperature is 10°C, and the hydrolysis time is 24 hours.

[0031] After hydrolysis, 0.001 parts by mass of ammonium fluoride was added and stirred at a temperature of 20° C., and then polymerized.

[0032] The polymerized hydrogel was subjected to aging treatment, the concentration of ammonium fluoride in the aging solution was 0.1M, and the volume ratio of the aging solution to the gel was 5:1.

[0033] The aging temperature is 80° C., and the aging time is 96 hours.

[0034] The aged hydrogel was dried under normal pressure. The drying process was 2 hours at 30°C, 2 hours at 60°C, 2 hours at 90°C, and 2 hours at 120°C.

Embodiment 3

[0036] Weigh 130 parts by mass of solvent water, add 0.2 parts by mass of acetic acid, then add 2.5 parts by mass of surfactant cetyltrimethylammonium chloride, stir well and add 110 parts by mass of precursor methyl trimethoxy base silane was stirred for hydrolysis.

[0037] The hydrolysis temperature is 30° C., and the hydrolysis time is 0.5 hour.

[0038] After hydrolysis, 0.004 parts by mass of ammonium fluoride was added and stirred at a temperature of 20° C., and then polymerized.

[0039] The polymerized hydrogel was subjected to aging treatment, the concentration of ammonium fluoride in the aging solution was 1.5M, and the volume ratio of the aging solution to the gel was 10:1.

[0040] The aging temperature is 120° C., and the aging time is 24 hours.

[0041] The aged hydrogel was dried under normal pressure. The drying process was 6 hours at 30°C, 6 hours at 60°C, 1 hour at 90°C, and 1 hour at 120°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com