High density interconnect circuit board screen printing machine assisting tool storing rack

A technology of high-density interconnection and auxiliary tools, which is applied in the field of auxiliary tool storage racks for high-density interconnection circuit board screen printing machines, and can solve the problem of inability to place auxiliary tools on the screen printing machine, auxiliary tools with different volumes and shapes, and messy workbenches And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following examples are used to further illustrate the present invention. The following examples are illustrative and not restrictive. The following examples cannot be used to limit the protection scope of the present invention.

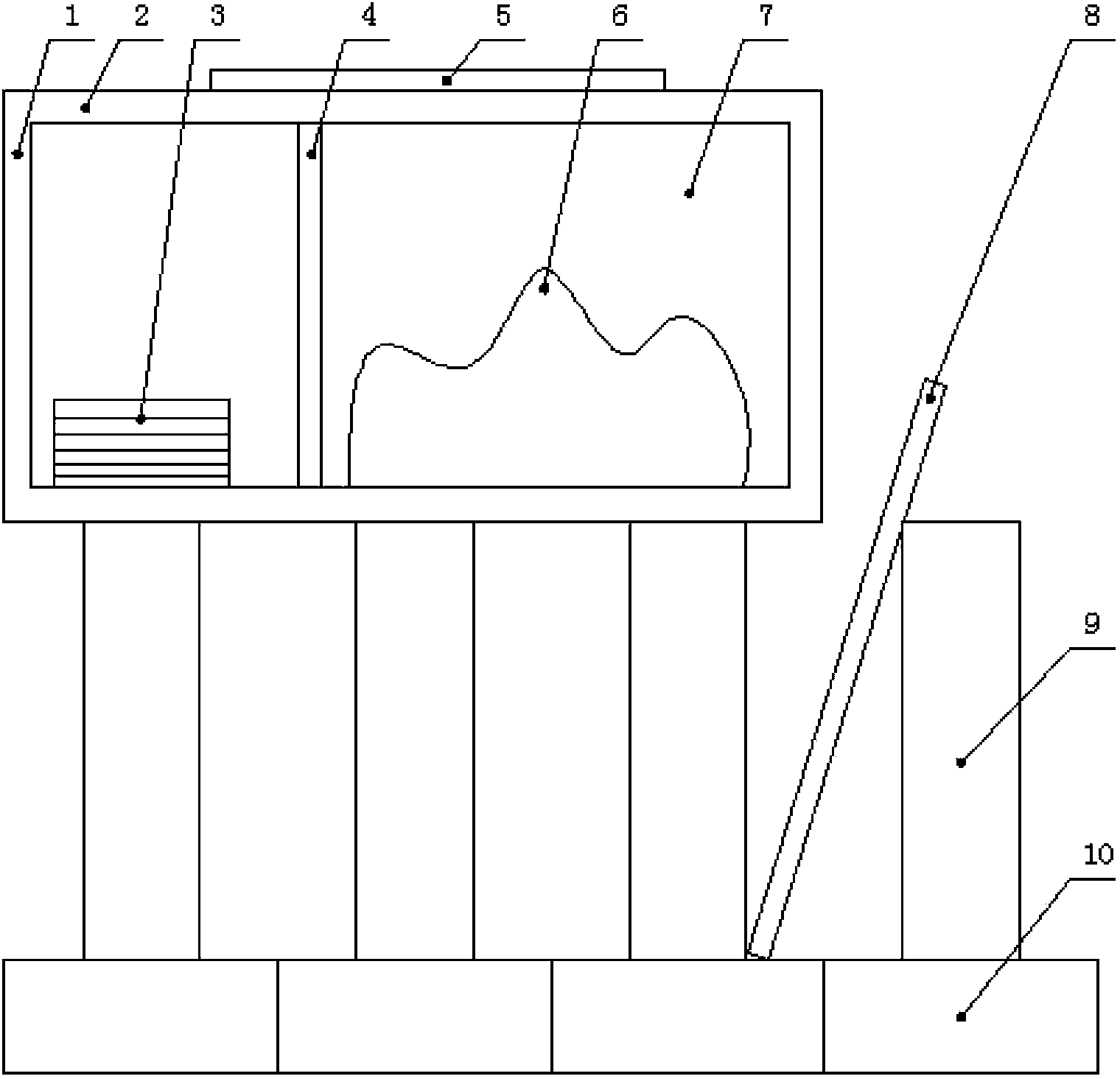

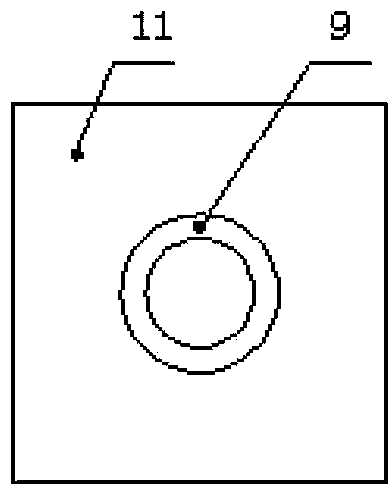

[0012] A high-density interconnect circuit board screen printing machine auxiliary tool storage rack, such as Figure 1~2 As shown, the innovation of the present invention is that it includes a base 10, a support column 9 and a frame. A plurality of support columns are arranged in a matrix above the base, and a frame is installed above a part of the support column on one side.

[0013] In this embodiment, the frame includes a side plate 1, a back plate 7, a horizontal plate 2 and a partition plate 4. The two side plates are vertically spaced apart and their rear ends are connected to the back plate. The upper and lower ends of the two side plates A horizontal plate is respectively connected, and at least one partition is installed between the tw...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap