Inner tub structure for washing machines

A washing machine and inner tub technology, applied in the field of washing machines, can solve problems such as unbalance, waste of energy, affecting the service life of the washing machine, etc., and achieve the effect of prolonging the service life and avoiding drumming or imbalance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

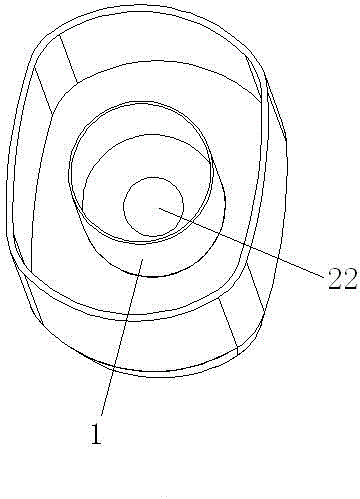

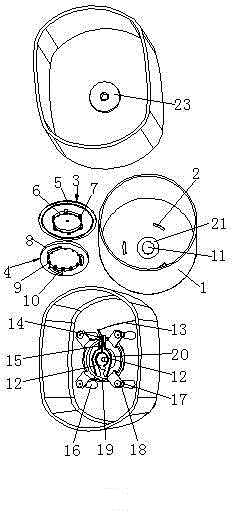

[0032] Such as figure 1 with figure 2 As shown, an inner tub structure of a washing machine includes an inner tub 1. The inner bottom of the inner tub 1 is provided with a buckle groove 2, and the buckle groove 2 is matched with a pulsator device, and the pulsator device includes an inner bottom connected to the inner tub 1. The wave blocking rotating plate 3 is provided with a collar 4 between the wave blocking rotating plate 3 and the inner bottom of the inner tub 1. The lower end of the wave blocking wheel device is connected with a locking device; when washing, the wave blocking rotating plate 3 of the present invention Driven by the inner shaft, first rotate clockwise, and then rotate counterclockwise together with the wave blocking plate 3 through the inner tub 1. This cycle can achieve the effect of washing; during dehydration, the inner barrel 1 rotates with the wave blocking plate 3, and finally To achieve the effect of dehydration, the lower end of the locking device ...

Embodiment 2

[0036] The difference between this embodiment and the first embodiment is that the dynamic balancing device includes a support column 16 arranged at the bottom of the base, the upper end of the support column 16 is provided with a second spring 17, and the upper end of the second spring 17 is provided with a sleeve column 18, The upper end of the sleeve column 18 is provided with a dynamic balance bracket 19, the locking clip 12 is provided at the upper end of the dynamic balance bracket 19, and the lower end of the dynamic balance bracket 19 is provided with a motor 20. The motor 20 is screwed to the inner shaft through a connecting sleeve. A shaft sleeve is provided between the connecting sleeve and the bottom of the base. At least three support columns 16 are provided at the bottom of the base. The upper ends of the three support columns 16 are provided with second springs 17, and the upper ends of each second spring 17 are provided with The sleeve column 18, in this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com