Model pile foundation with horizontal dynamic loading device

A loading device and horizontal loading technology, which is applied in basic structure engineering, basic structure testing, construction, etc., can solve the problems of inconvenient operation, high construction cost, complicated principle, etc., and achieve the effect of improving similarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

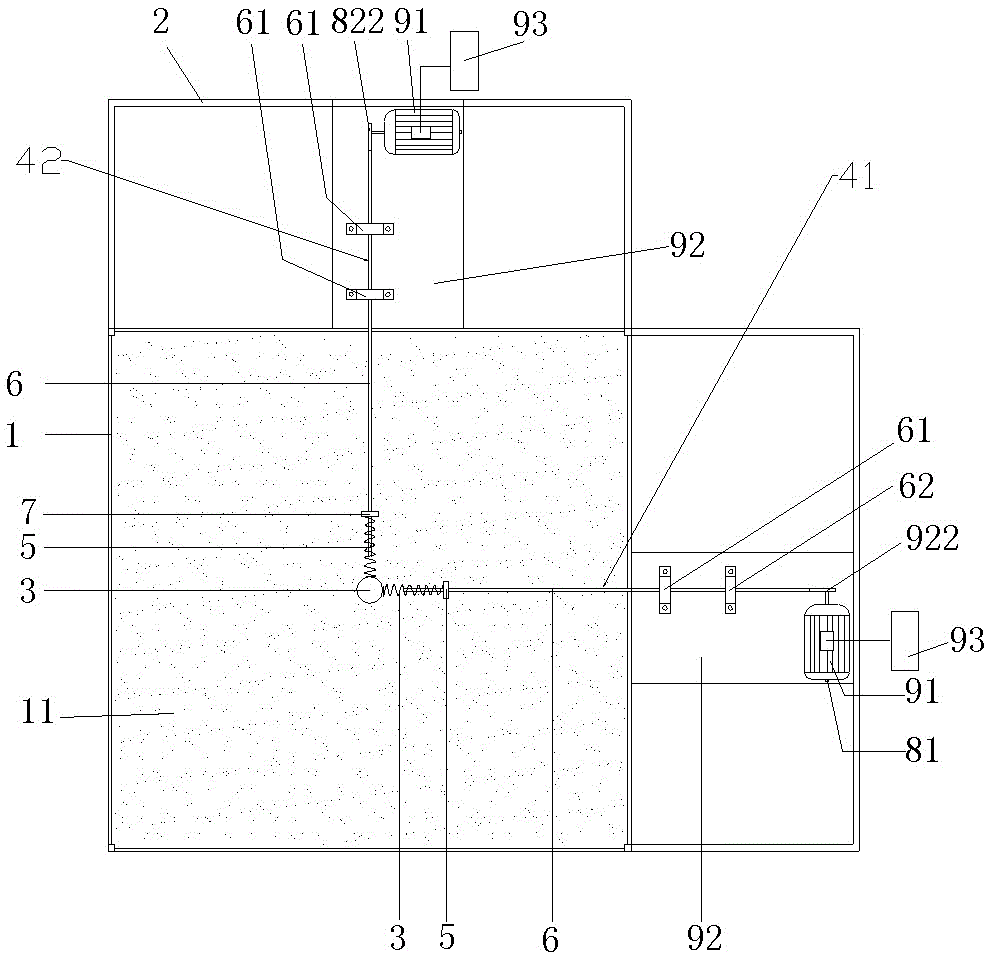

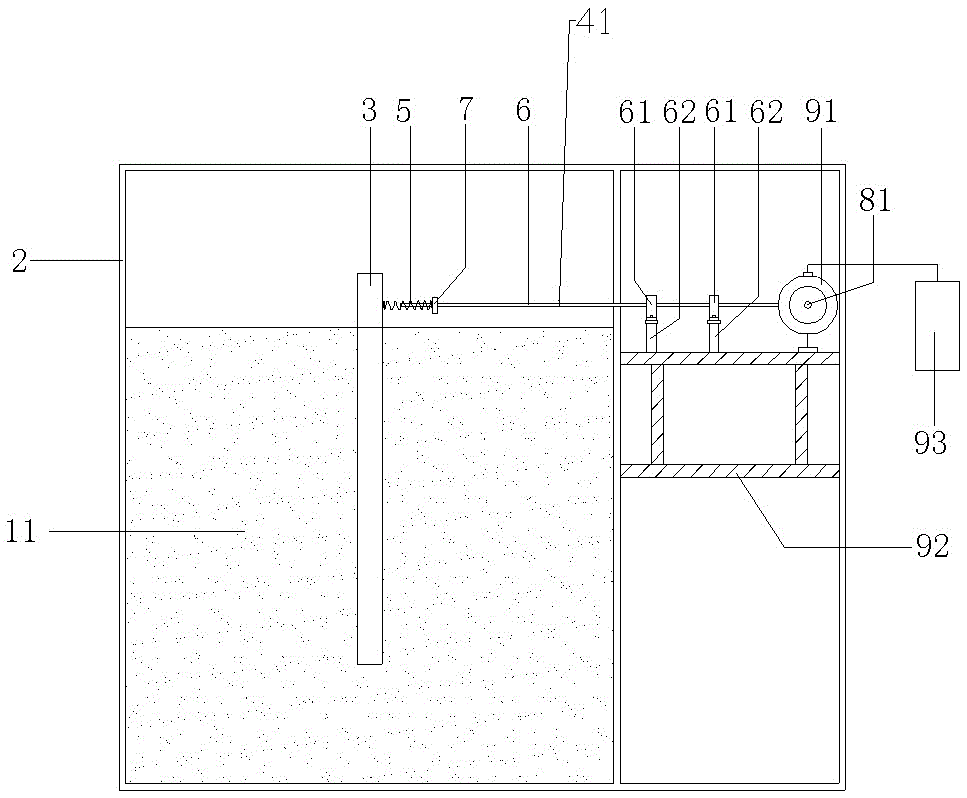

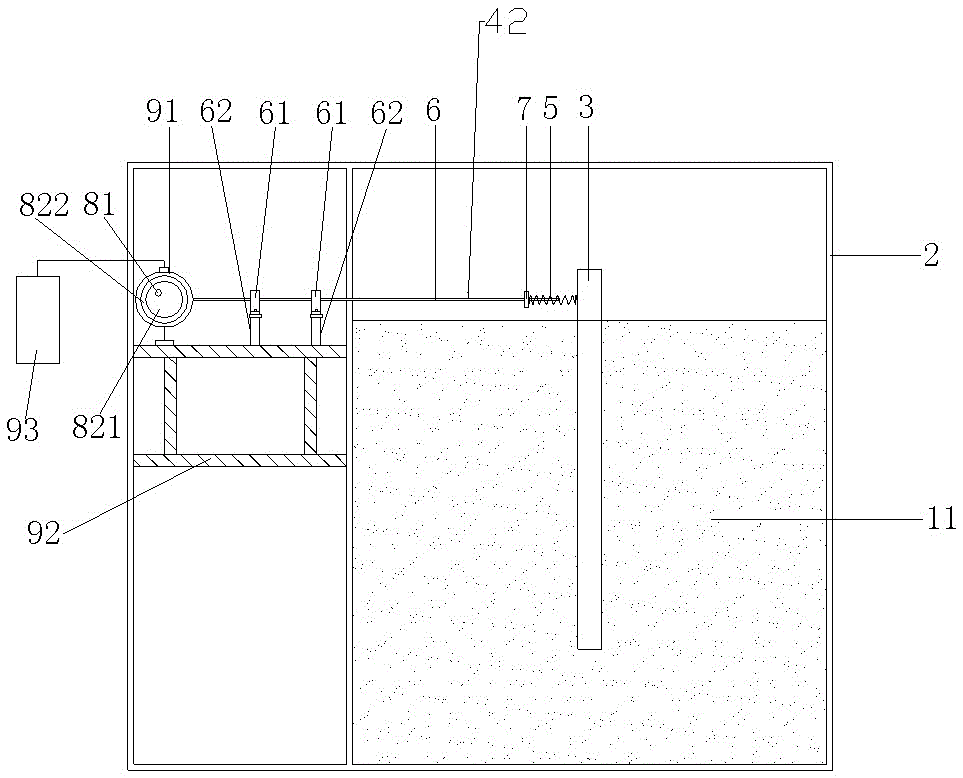

[0031] Embodiment 1 of the model pile foundation with the horizontal dynamic loading device of the present invention, such as Figure 1-8 Shown: the model pile foundation with horizontal dynamic loading device includes soil box 1 , loading frame 2 , model pile 3 and horizontal loading mechanism 4 .

[0032] The soil box 1 has a cube structure, and the soil box 1 is filled with soil body 11 . The model pile 3 extends up and down, the model pile 3 is arranged in the soil box 1, the model pile 3 is located at the center of the soil box 1, the lower part of the model pile 3 is buried in the soil box 1 and is fixed by the soil in the soil box 1, The upper part of the model pile 3 protrudes from the soil body in the soil box 1 . The loading frame is fixed on the outer periphery of the soil box. The loading frame 2 is made of steel. The horizontal loading mechanism 4 is assembled on the loading frame 2 .

[0033] The horizontal loading mechanism 4 is used to apply a horizontal lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com