Cage type multi-shaft optical system mounting rack

A technology of optical system and mounting frame, which is applied in the field of optical system installation and adjustment mechanism, and can solve problems such as difficulty in changing relative distance, time-consuming and labor-intensive precision, and large operating platform area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

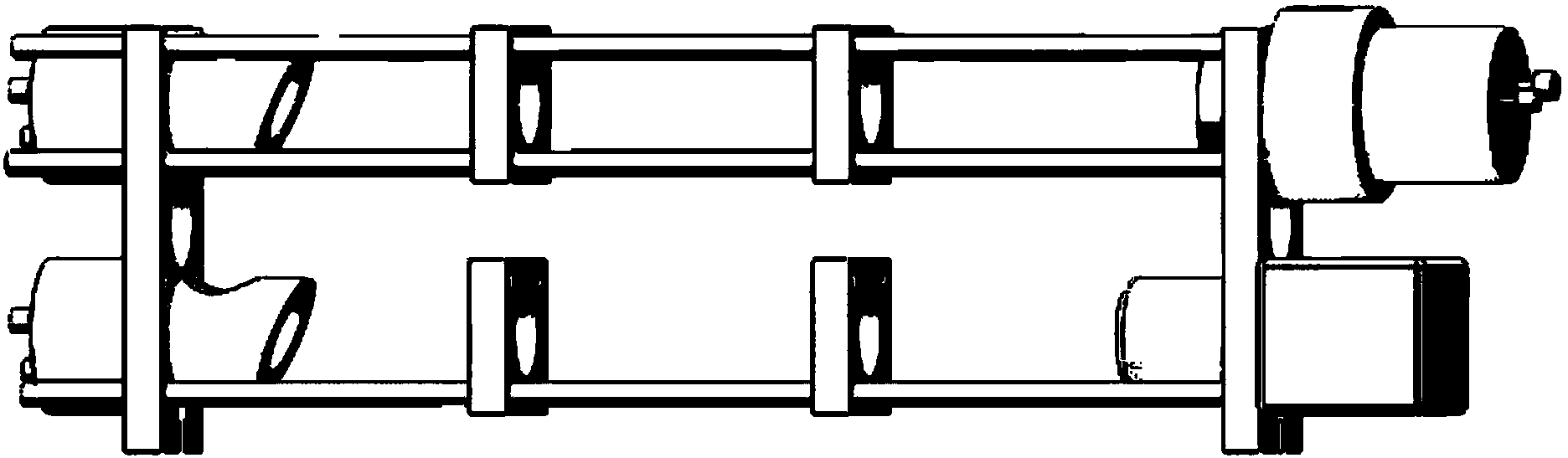

[0018] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, the cage-type multi-axis optical system mounting frame described in this embodiment includes at least two optical element mounting frames and at least two guide rods, and at least one optical element mounting hole is provided on the optical element mounting frame, Four guide rod mounting holes are evenly distributed on the outside of each optical component mounting hole, and the guide rods pass through the guide rod mounting holes of multiple optical component mounting frames in turn, and the bottoms of at least two optical component mounting frames are provided with mounting frame fixing holes , the mounting frame fixing hole is used to fix the cage multi-axis optical system mounting frame on the optical table.

[0019] The cage-type multi-axis optical system mounting frame described in this embodiment includes multiple optical element mounting frames and multiple guide rod...

specific Embodiment approach 2

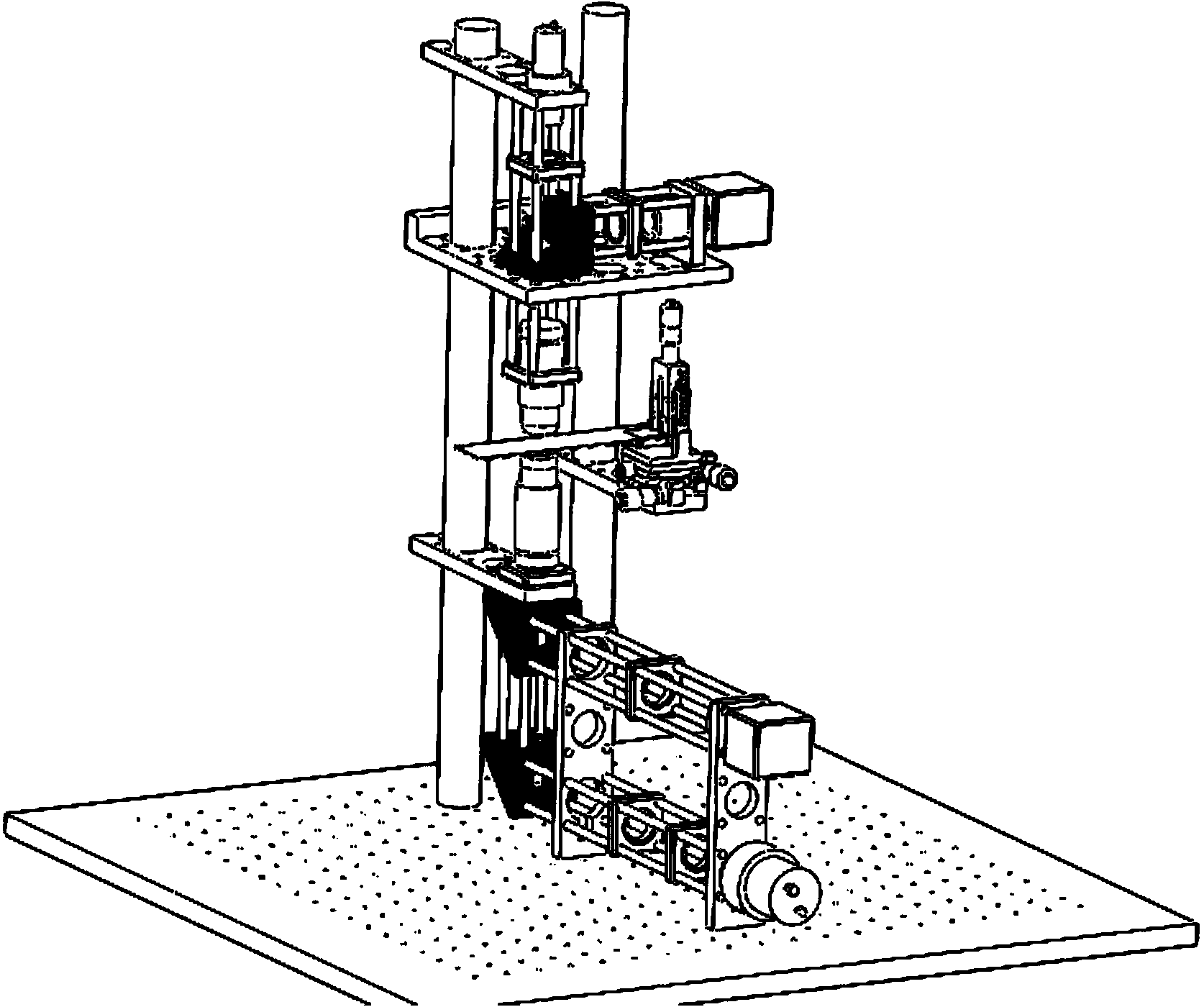

[0020] Specific implementation mode two: combination figure 2 Describe this embodiment. This embodiment is a further limitation of the cage-type multi-axis optical system mount described in Embodiment 1. In this embodiment, the cage-type multi-axis optical system mount further includes N pillars, and N is a positive integer, the pillars are cylindrical, and each pillar fixes at least one optical element mounting frame, and the optical element mounting frame is fixed on the pillar through any optical element mounting hole thereon.

[0021] In practical applications, the optical element mounting frame is fixedly connected to the pillar through a jacking screw. When there is 45-degree reflection in the optical path, the pillar can be fixed vertically on the optical platform, and the pillar can be inserted through the optical element mounting holes on one or more optical element mounting frames according to actual needs, and other optical element mounting frames can be fixed on t...

specific Embodiment approach 3

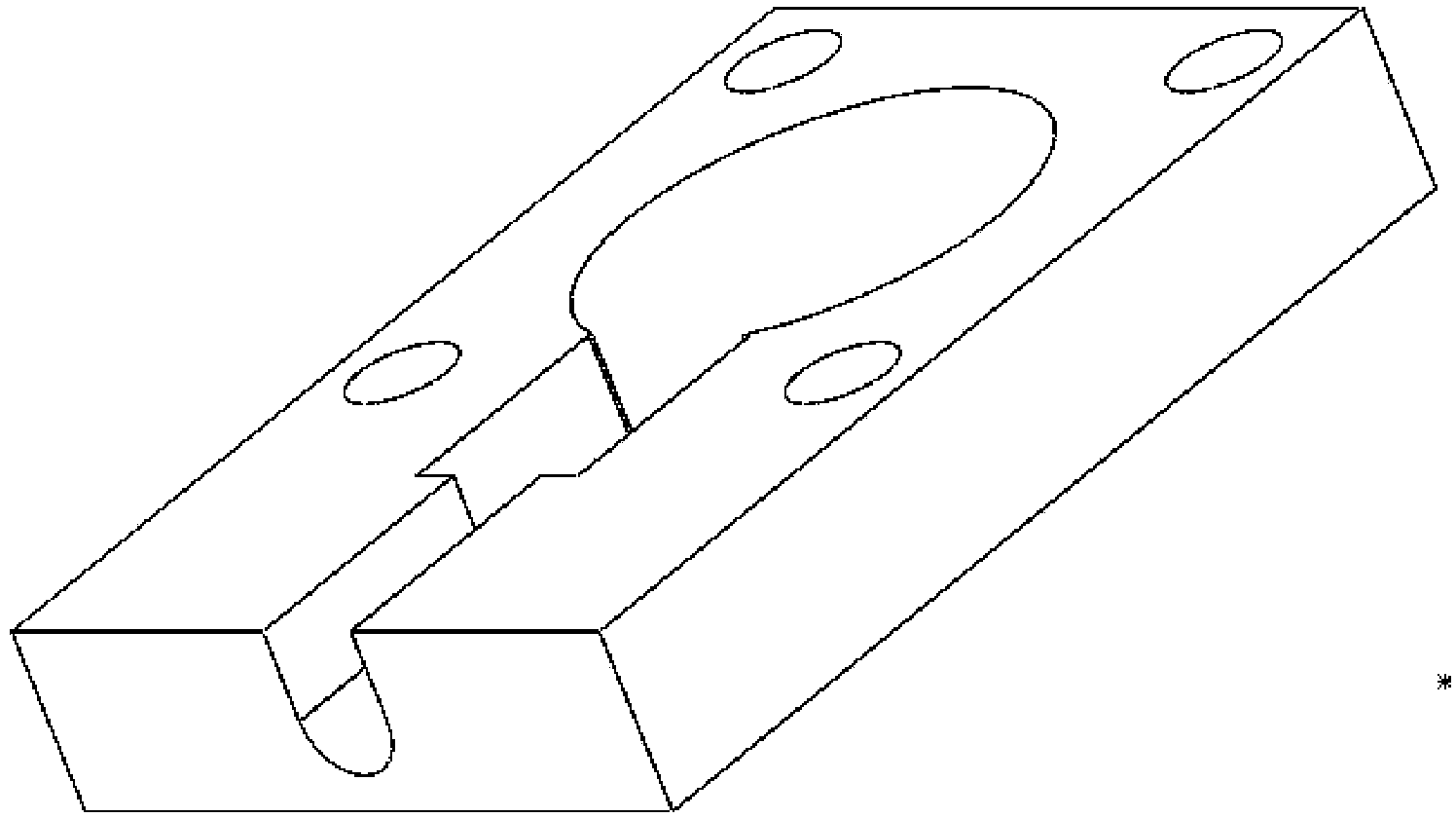

[0022] Specific Embodiment Three: This embodiment is a further limitation of the cage-type multi-axis optical system mounting frame described in Embodiment 2. In this embodiment, the optical element mounting frame is also provided with threaded holes, and the threaded The holes are used to fix the optical adjustment mount.

[0023] In this embodiment, the optical adjustment frame is installed on the optical element mounting frame, and other optical elements are added to the optical adjustment frame to meet the needs of different optical systems, and the propagation of light in space can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com