accompanying cable

A traveling cable and cabling technology, applied in the field of elevator cables, can solve the problems of high manufacturing cost and heavy weight, and achieve the effect of reducing cost and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

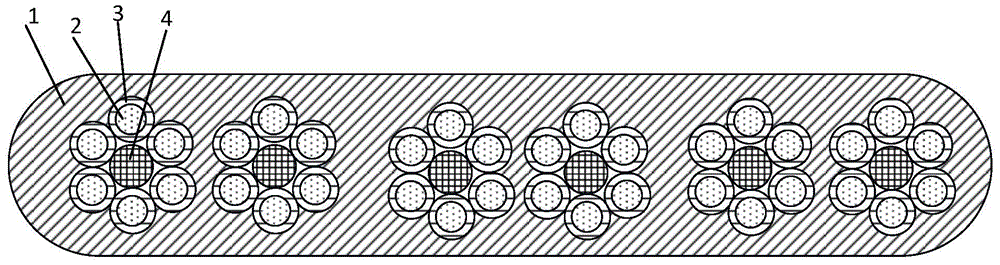

[0023] Such as figure 1 As shown, the accompanying cable of the present invention includes a sheath 1 , a conductive core 2 , an insulating layer 3 and a filler wire 4 .

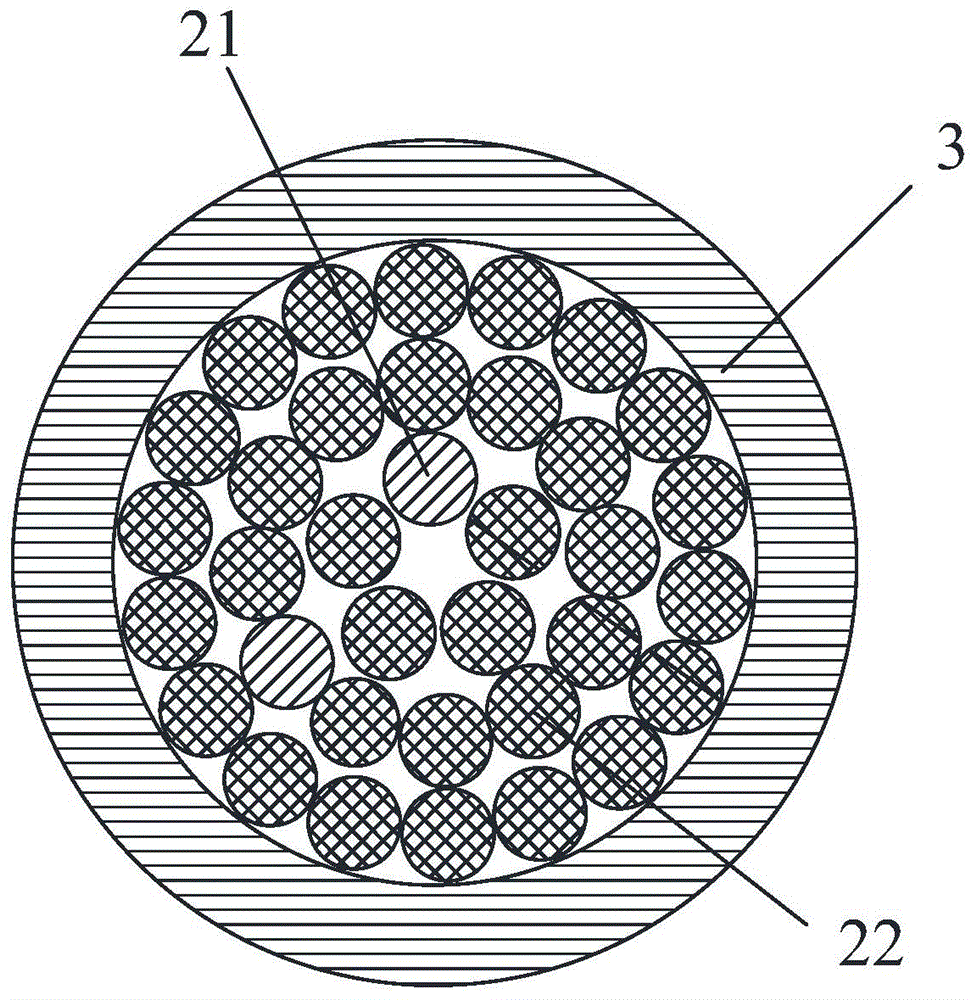

[0024] Such as figure 2 As shown, each conductive wire core 2 includes several copper-clad aluminum conductors 22 and several copper-clad steel conductors 21, and the copper-clad aluminum conductors 22 and copper-clad steel conductors 21 are twisted together. The twisting of conductors is used in this field and belongs to Prior art, so do not go into details here. ( figure 2 It is only a schematic diagram of the internal structure of the insulated wire core, and the numbers of copper-clad aluminum conductors 22 and copper-clad steel conductors 21 in the figure are shown arbitrarily. )

[0025] Each conductive wire core 2 is covered with an insulating layer 3, and each conductive wire core 2 and the insulating layer 3 covering its periphery constitute an insulating wire core. Each of the insulated core...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com