Fuel tank cap lock with a reduced number of components

A storage tank cover and equipment technology, applied in the direction of connecting components, mechanical equipment, building locks, etc., can solve the problems of high assembly cost, susceptibility to interference, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

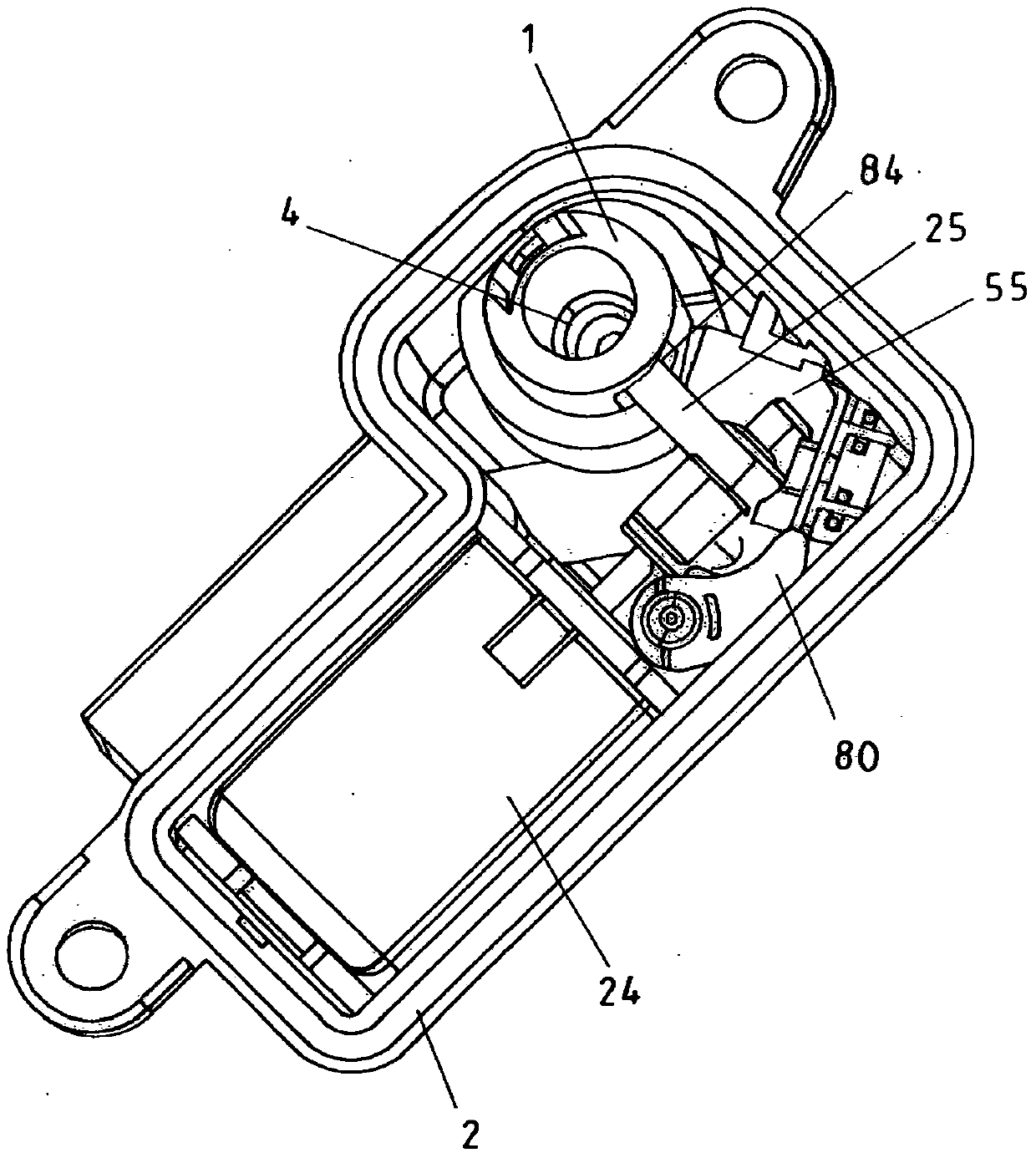

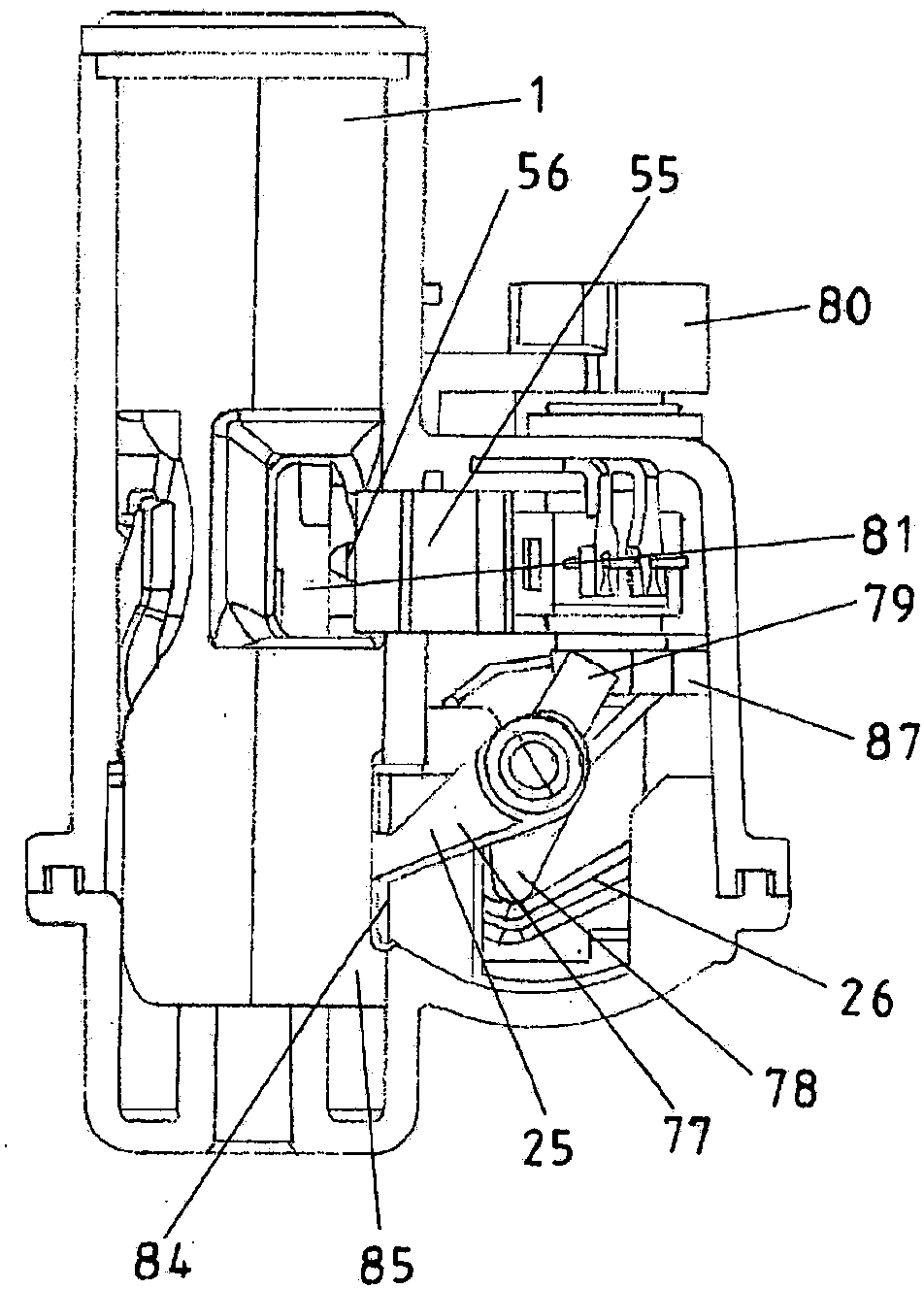

[0045] figure 1 A view of the interior of the lock device is shown with the locking pin 1 in the open position. In order to make the illustration more intuitive, only a part of the housing 2 is shown which is marked with the corresponding reference number. On its peripheral surface 7 the locking pin 1 has a sliding guide 5 which, in cooperation with the pin 18 , serves as a positive guide 8 between the locking pin 1 and the housing 2 . The reference number 24 designates a drive in the form of a motor for the locking pawl 25 by means of which the locking pin 1 is fixed in the locked position so that it cannot be actuated further.

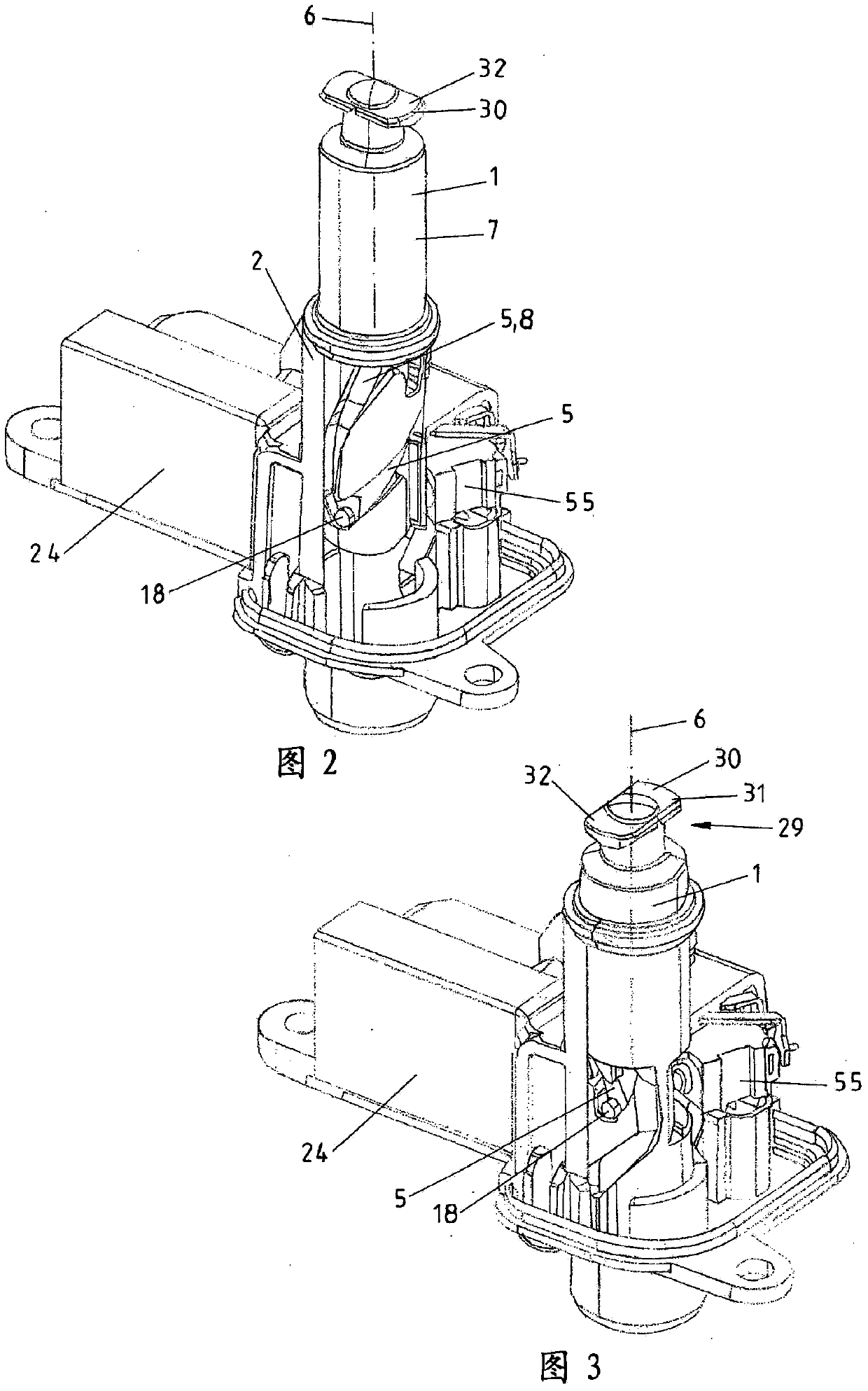

[0046] in accordance with figure 2 In the schematic diagram of , the locking pin 1 is placed in its closed position, that is to say pressed down along its longitudinal axis 6 . This is achieved by a tank cover or charging cover, not visible here, with which the locking pin 1 is in contact at its upper end 19 . Effective for this is a mechanism 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com