Potato harvester soil cutting mechanism

A technology for harvesters and potatoes, which is applied to digging harvesters, harvesters, agricultural machinery and implements, etc., can solve problems such as shortened service life, looseness, and accelerated cutter head, and achieve increased stability, reliable work, and reduced wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described further according to accompanying drawing:

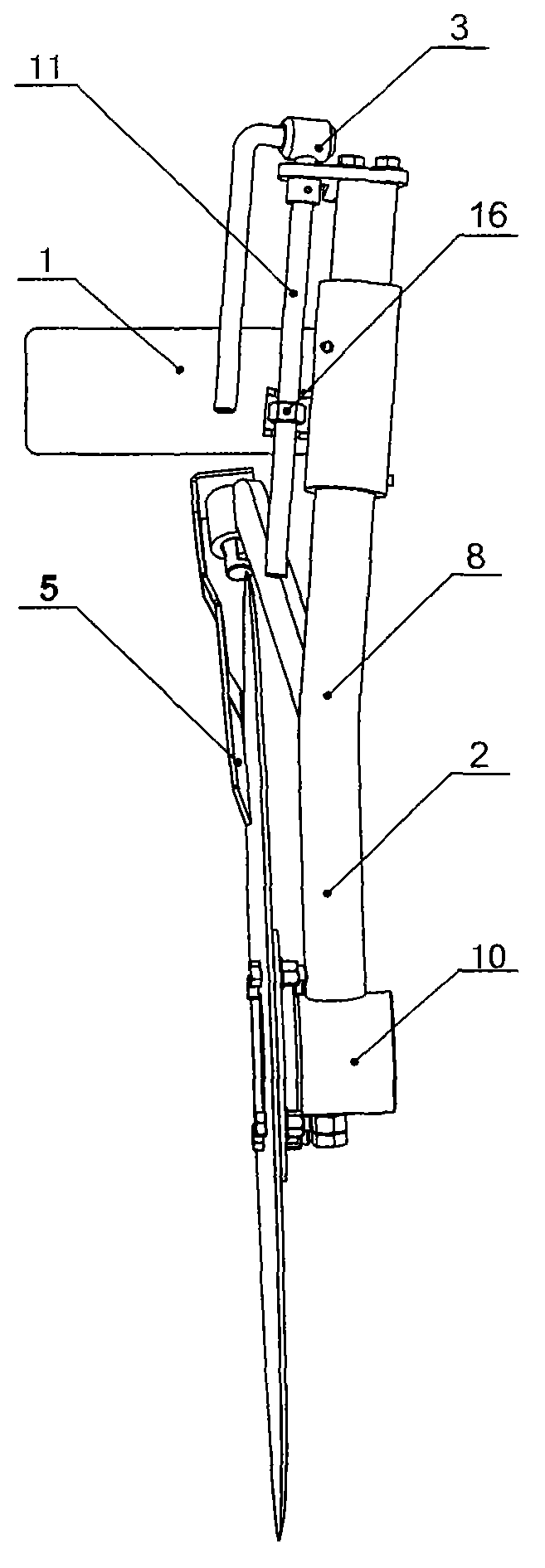

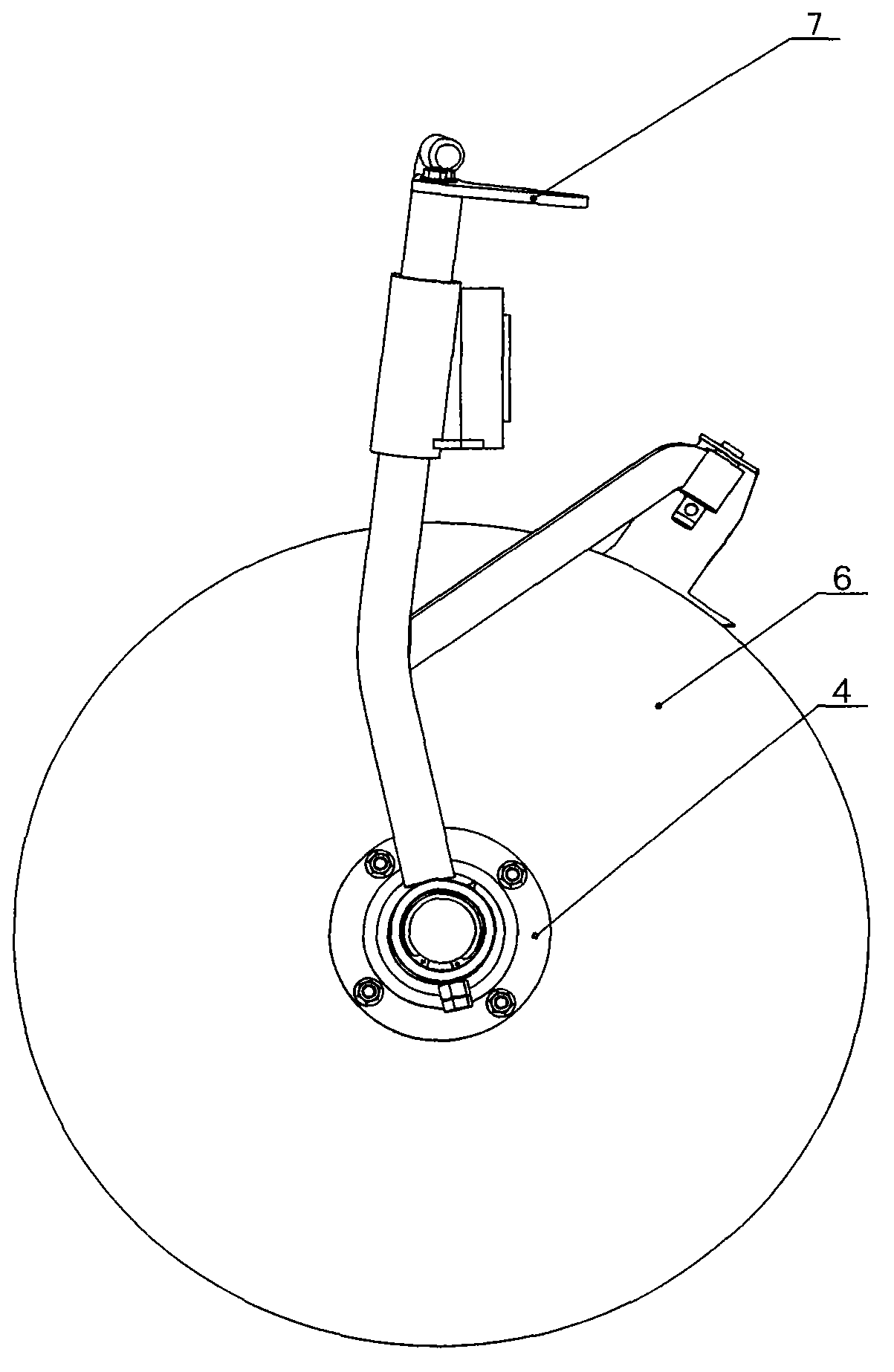

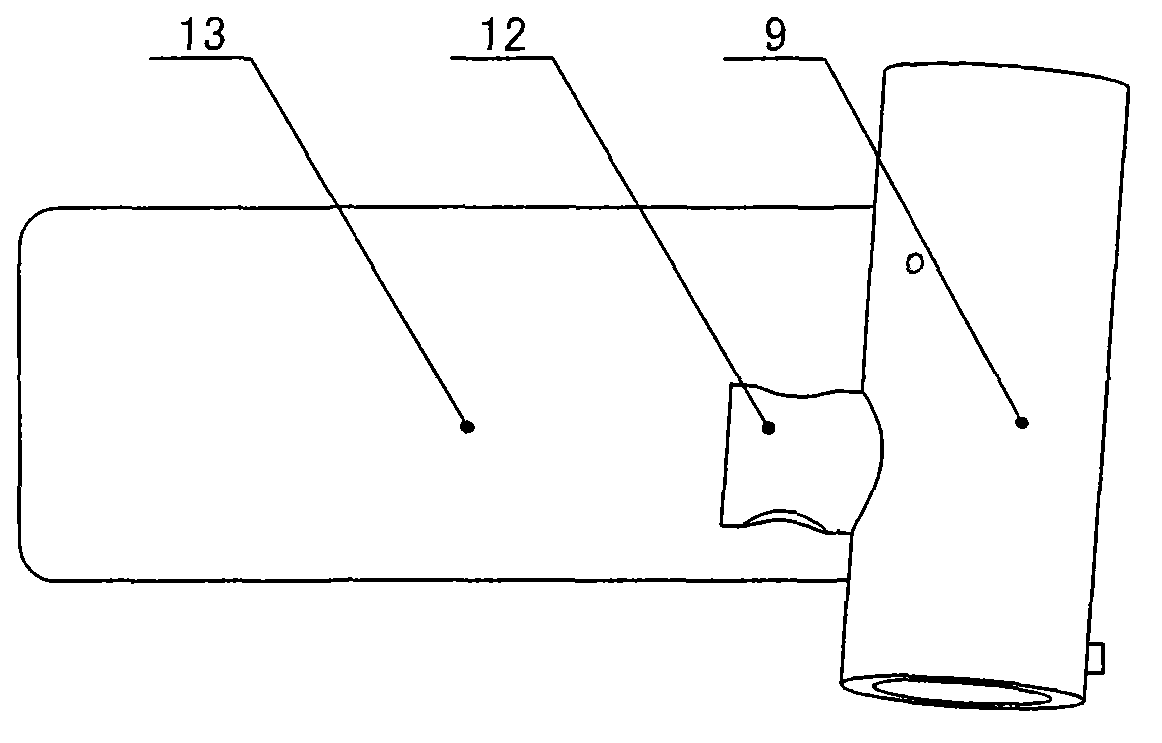

[0015] The present invention mainly consists of knife rest welding (1), knife arm welding (2), adjusting screw assembly (3), knife seat welding (4), scraper welding (5), disc knife (6) , Upper connecting plate (7) etc. are formed. The knife arm (8) in the knife arm welding (2) passes through the knife arm sleeve (9) on the knife rest welding (1), the upper end is connected with the upper connecting plate (7), and the lower end is welded on it The bearing seat (10) is connected with the knife seat welding (4), the disc knife (6) is installed on the knife seat welding (4), and the screw (11) in the adjustment screw assembly (3) passes through the upper connecting plate The mounting hole of (7) is matched with the nut (16) placed in the nut sleeve (12) in the knife holder welding (1), and the scraper welding (5) is installed on the knife arm welding (2) , located on the inner side of the disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com