A preheater inner cylinder hanging piece

A technology of preheater and inner cylinder, applied in the field of preheater inner cylinder hanging of cement production line, can solve the problem of high cost of purchasing and management of spare parts, harsh working environment of preheater inner cylinder hanging, and the life of the hanging film. Less than one year and other problems, to achieve the effect of increasing thickness, reducing weight, and convenient variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

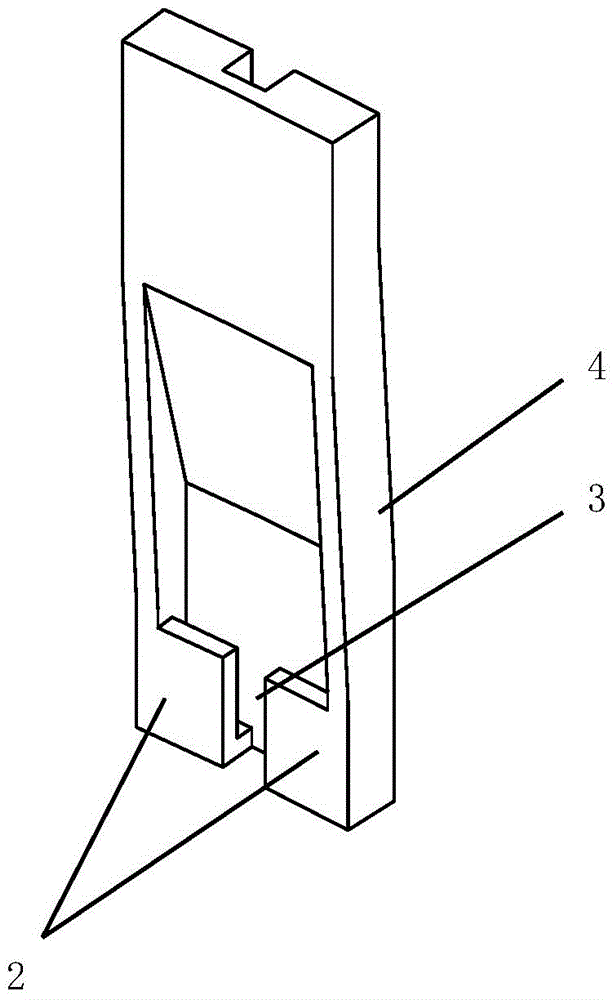

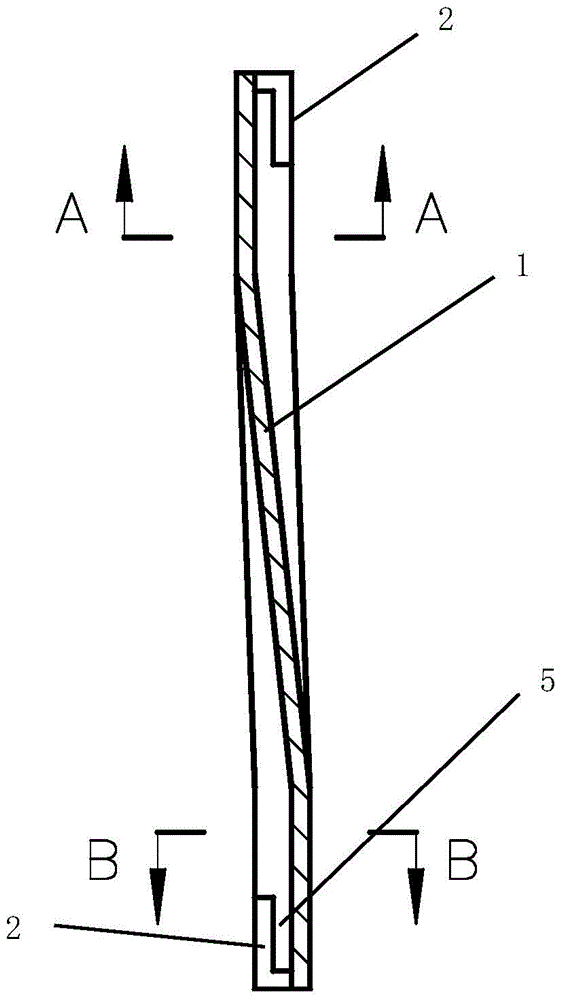

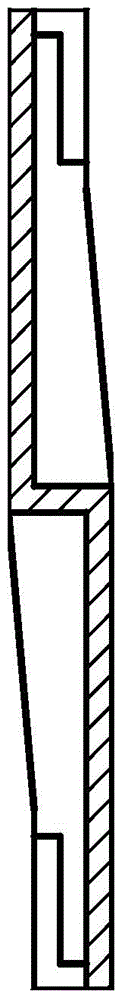

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] Such as Figures 1 to 8 As shown, the present invention provides a preheater inner cylinder hanging piece, including a circular arc hanging piece body 1, the hanging piece body 1 is an arc-shaped folding plate, and the upper and lower ends of the hanging piece body 1 are connecting plates 2. The upper connecting plate 2 is located outside the arc of the coupon body 1, the lower connecting plate 2 is located inside the arc of the coupon body 1, and the upper and lower surfaces of the connecting plate 2 are respectively flush with the upper and lower surfaces of the coupon body 1. There is a vertical groove 3 in the middle of the connecting plate 2, and the vertical groove 3 runs through the thickness direction of the entire connecting plate 2. There is a side plate 4 on the left and right sides of the hanging piece body 1, and the connecting plate 2 and the hangi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com