Rotor of a rotating electrical machine

A technology for rotating electrical machines and rotors, which is applied in the field of rotors of rotating electrical machines, and can solve problems such as demagnetization of permanent magnets 113, and achieve the effect of suppressing demagnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

[0167] Next, a rotor 10 of a rotating electric machine according to a second embodiment of the present invention will be described. The basic structure of the rotor 10 of the present embodiment is the same as that of the first embodiment, so the description will focus on different parts, and the description of the same or corresponding parts will be omitted or simplified by assigning the same reference numerals.

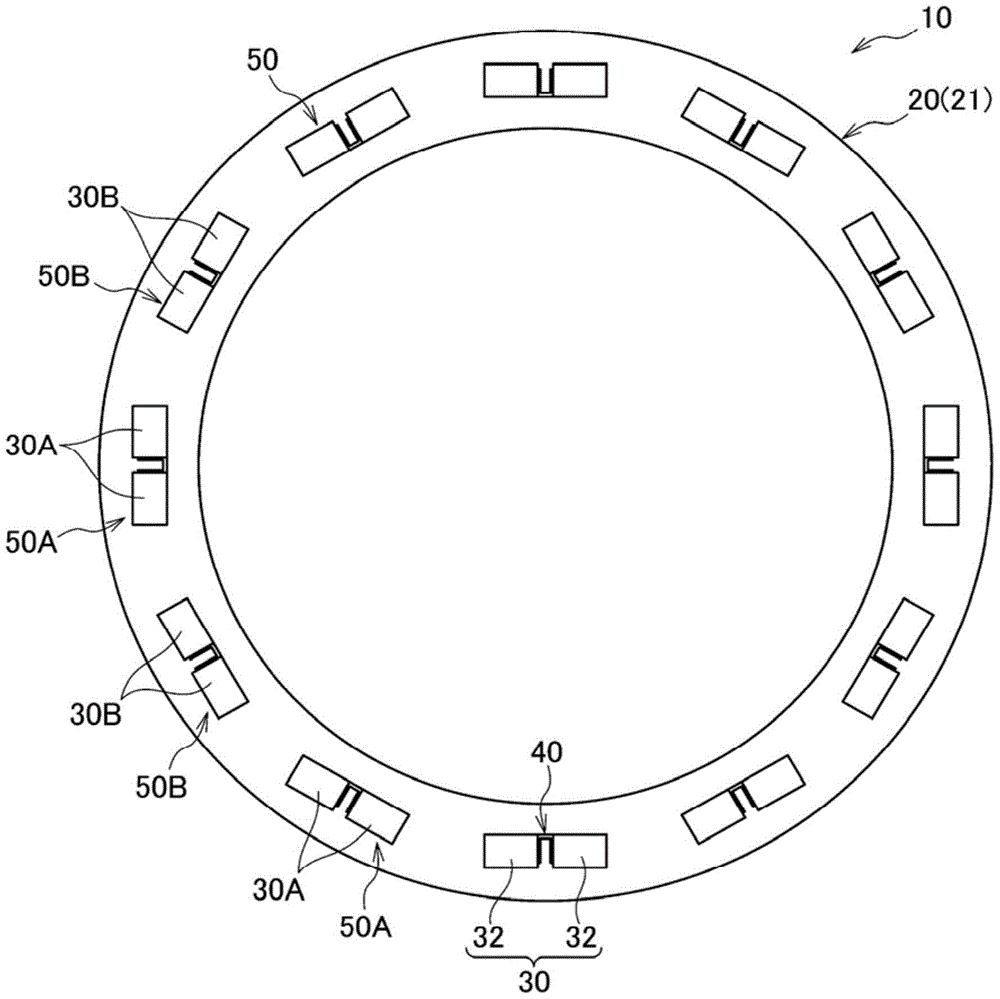

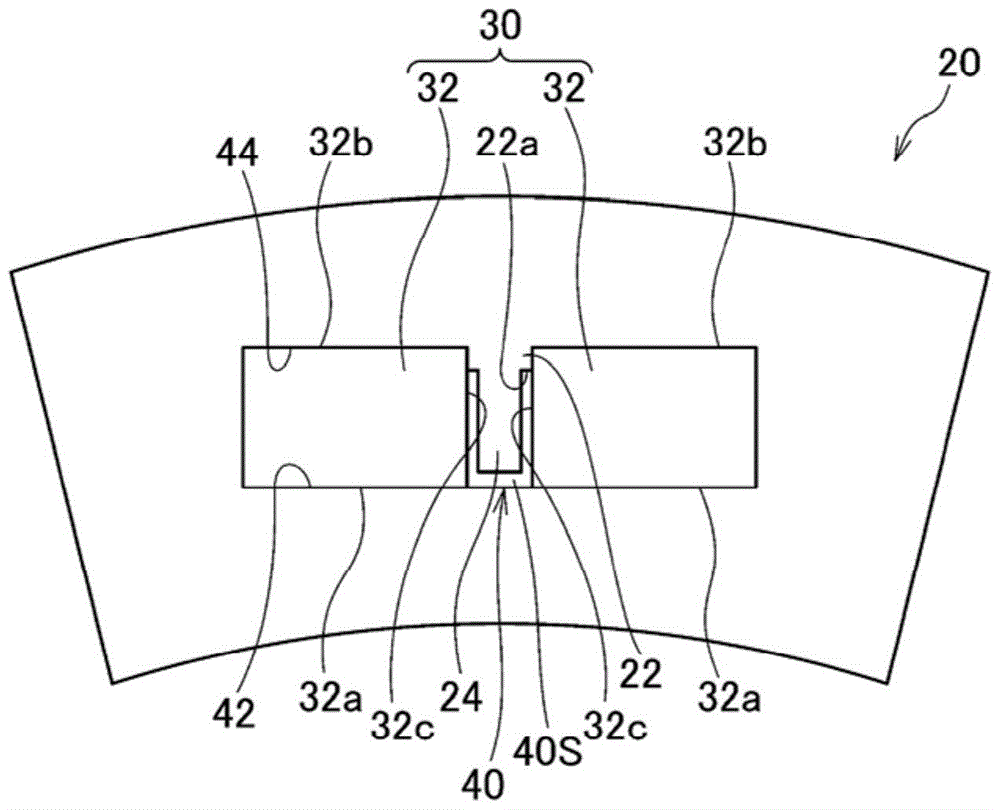

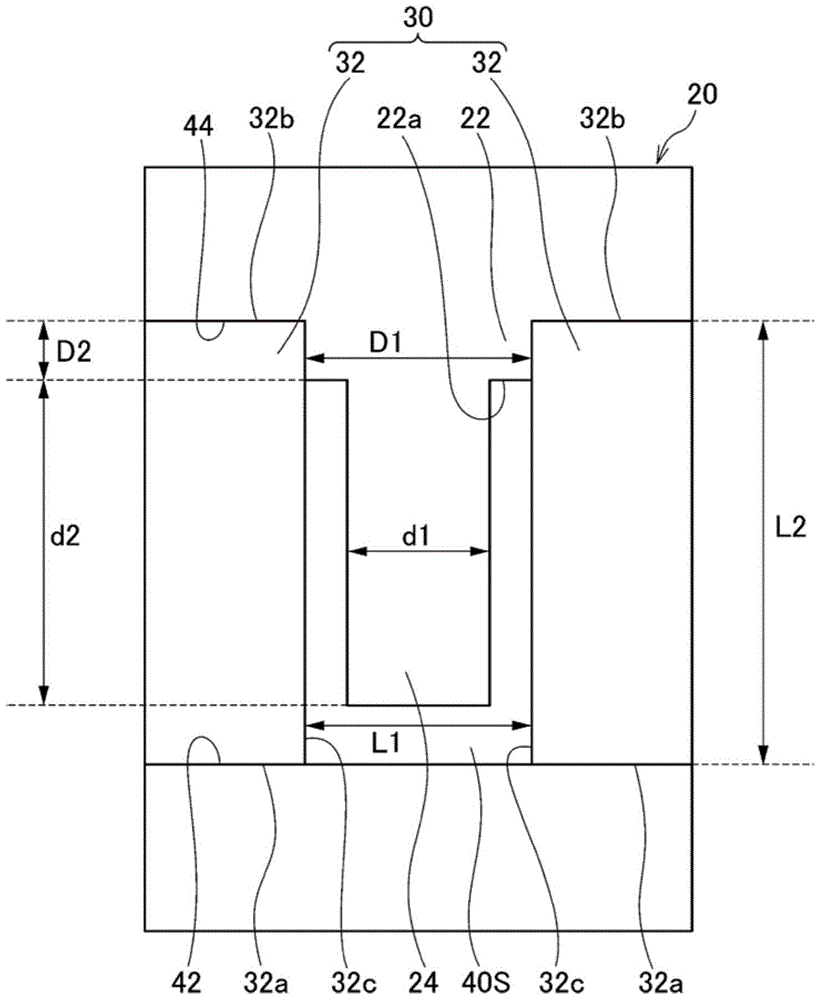

[0168] like Figure 20 and Figure 21 As shown, the rotor core 20 of the present embodiment is formed so as to extend radially inward from the outer peripheral portion 44 of the magnet insertion hole 40 between the circumferentially adjacent permanent magnet pieces 32, and the permanent magnet The retaining portion 22 on which the circumferential inner end portion 32c of the piece 32 abuts is formed so as to extend radially outward from the inner peripheral edge portion 42 of the magnet insertion hole 40 between the circumferentially adjacent permanent magnet pieces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com