Transfer target object separation apparatus, transferring apparatus, image formation apparatus, and transfer target object separation control method

A technology for separating devices and transfer pieces, which is applied in the fields of electric recording technology using charge patterns, equipment for electric recording technology using charge patterns, and electrography, and can solve problems such as impact and difficult separation of transfer pieces reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

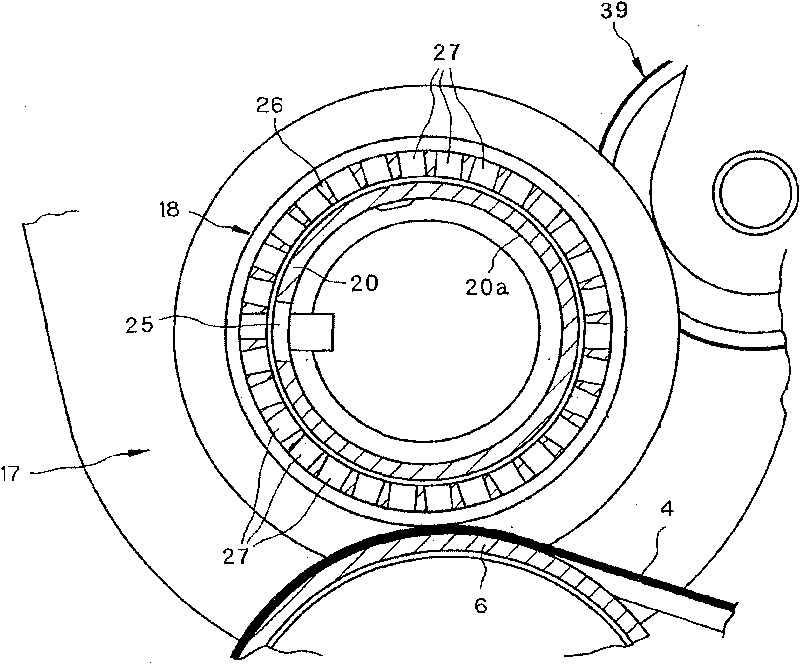

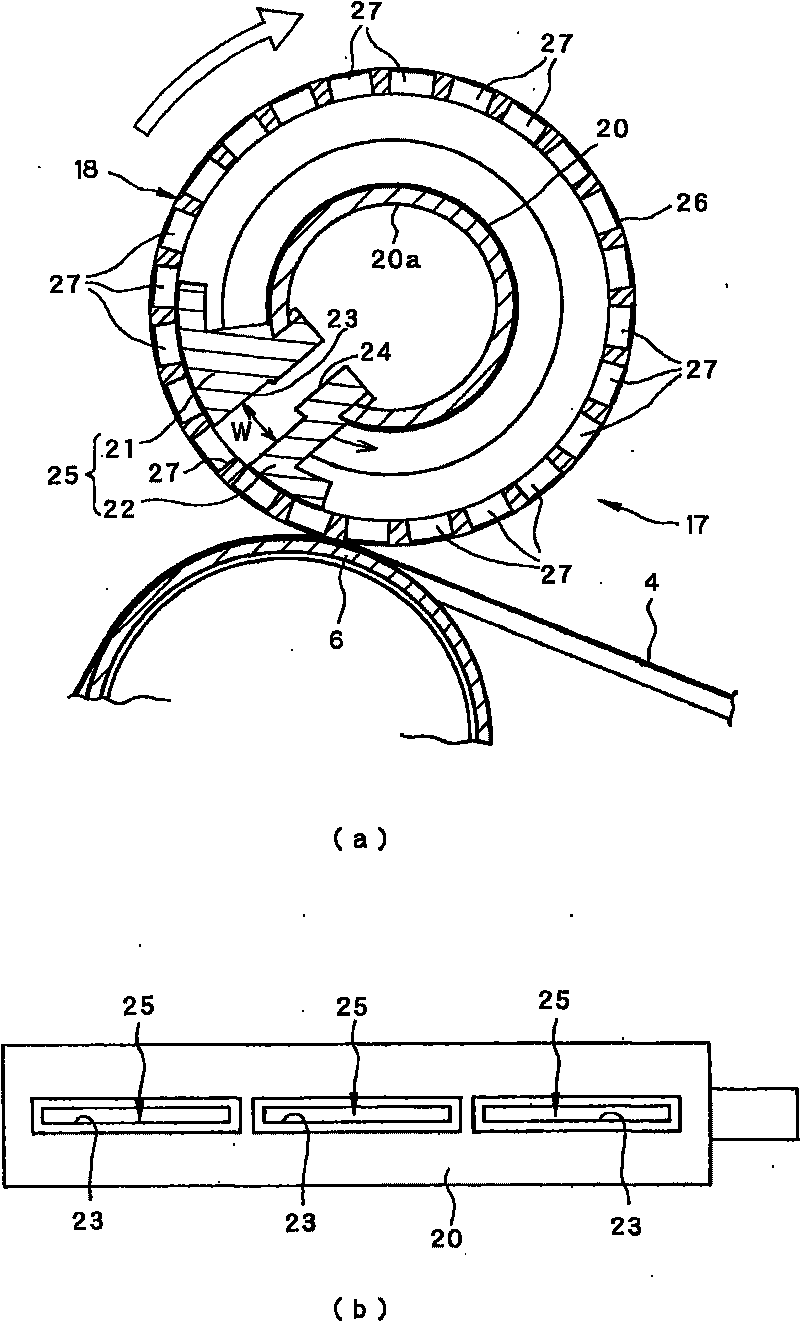

[0021] Hereinafter, preferred modes for implementing the present invention will be described with reference to the drawings.

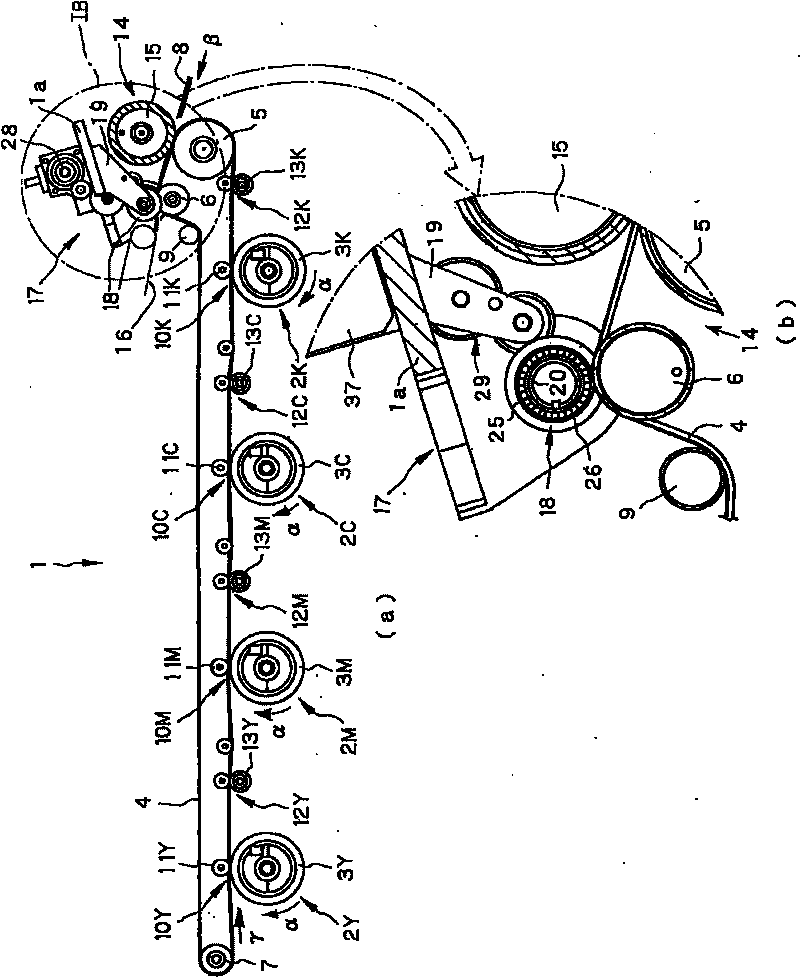

[0022] figure 1 (a) is a figure which schematically and partially shows an example of embodiment of the image forming apparatus which has the transfer material separation apparatus of this invention, figure 1 (b) is figure 1 Enlarged view of part IB of (a).

[0023] Such as figure 1 As shown in (a), the image forming apparatus 1 of this example has image forming units 2Y, 2M using liquid developers of yellow (Y), magenta (M), cyan (C), and black (K) arranged in series. , 2C, 2K. Here, among the imaging units 2Y, 2M, 2C, and 2K, 2Y indicates a yellow imaging unit, 2M indicates a magenta imaging unit, 2C indicates a cyan imaging unit, and 2K indicates a black imaging unit. In addition, also in other components, Y, M, C, and K of each color are added to the codes of the components to represent the components of each color.

[0024] Each imaging unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com