Shift device

一种换挡装置、挡孔的技术,应用在控制装置、传动装置控制、运输和包装等方向,能够解决无法有效地限制换挡杆转动、邻接部强度降低等问题,达到抑制小型化、抑制强度降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

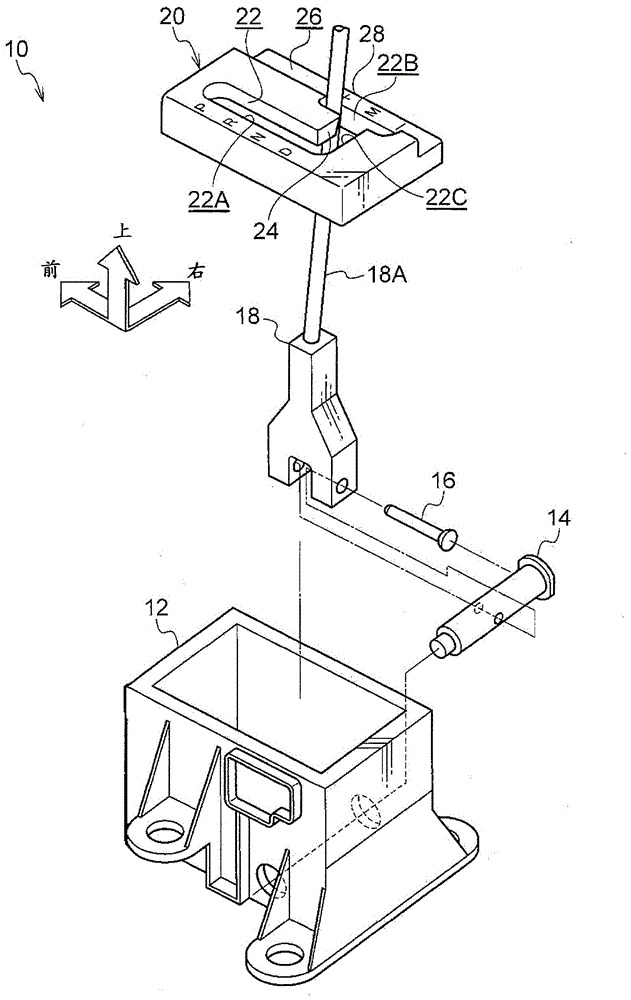

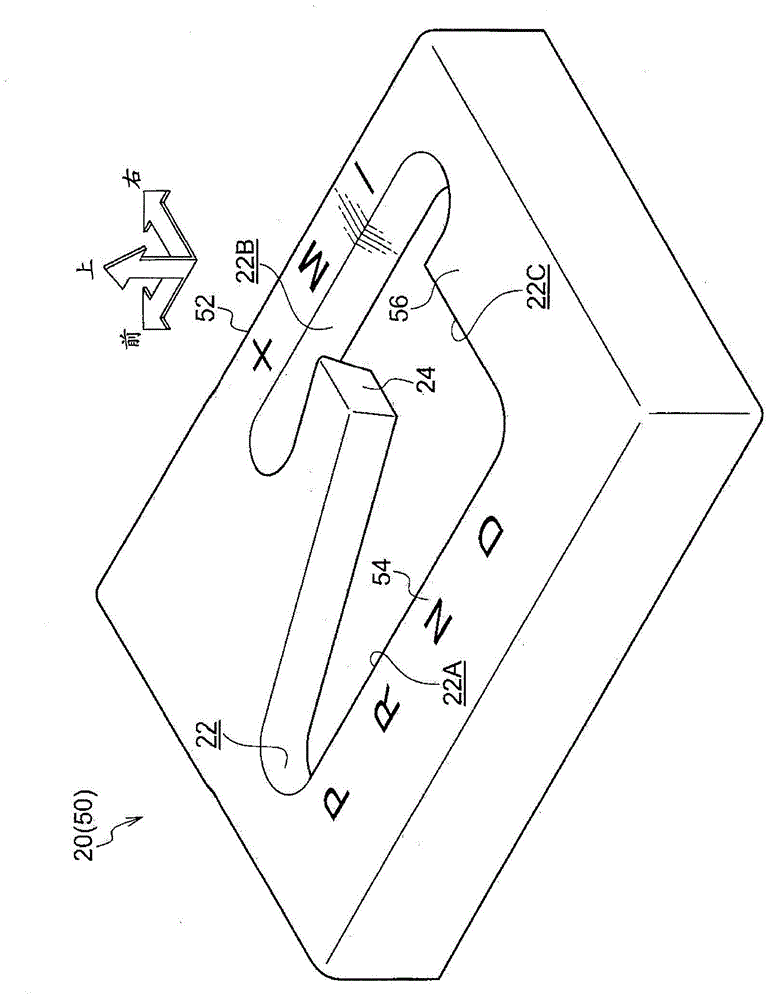

[0020] figure 1 In , the shift lever device 10 as the shift device according to the first embodiment of the present invention is shown in an exploded perspective view viewed obliquely from the left rear of the vehicle, figure 2 The selector lever device 10 is shown in a sectional view viewed from the rear of the vehicle. In addition, in the drawings, the front of the vehicle is indicated by an arrow FR, the right side of the vehicle is indicated by an arrow RH, and the upward direction is indicated by an arrow UP.

[0021] The shift lever device 10 of the present embodiment is a so-called floor-type shift lever, and is installed on a floor portion (floor) of the vehicle interior that is the vehicle body side.

[0022] Such as figure 1 as well as figure 2 As shown, the shift lever device 10 includes a substantially rectangular parallelepiped box-shaped case 12 as a supporting member. The case 12 is fixed to the floor portion of the vehicle interior and has an open upper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com