Armature molded structure

A technology of mold and armature, applied in the direction of magnetic circuit shape/style/structure, winding conductor shape/style/structure, winding insulation shape/style/structure, etc. The effect of reducing moment and securing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following detailed description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of the disclosed embodiments. It may be evident, however, that one or more embodiments may be practiced without these specific details. In other instances, well-known structures and devices are shown schematically in order to simplify the drawings.

[0020] Hereinafter, a mold structure of a motor armature according to an embodiment of the present invention will be described in detail with reference to the drawings.

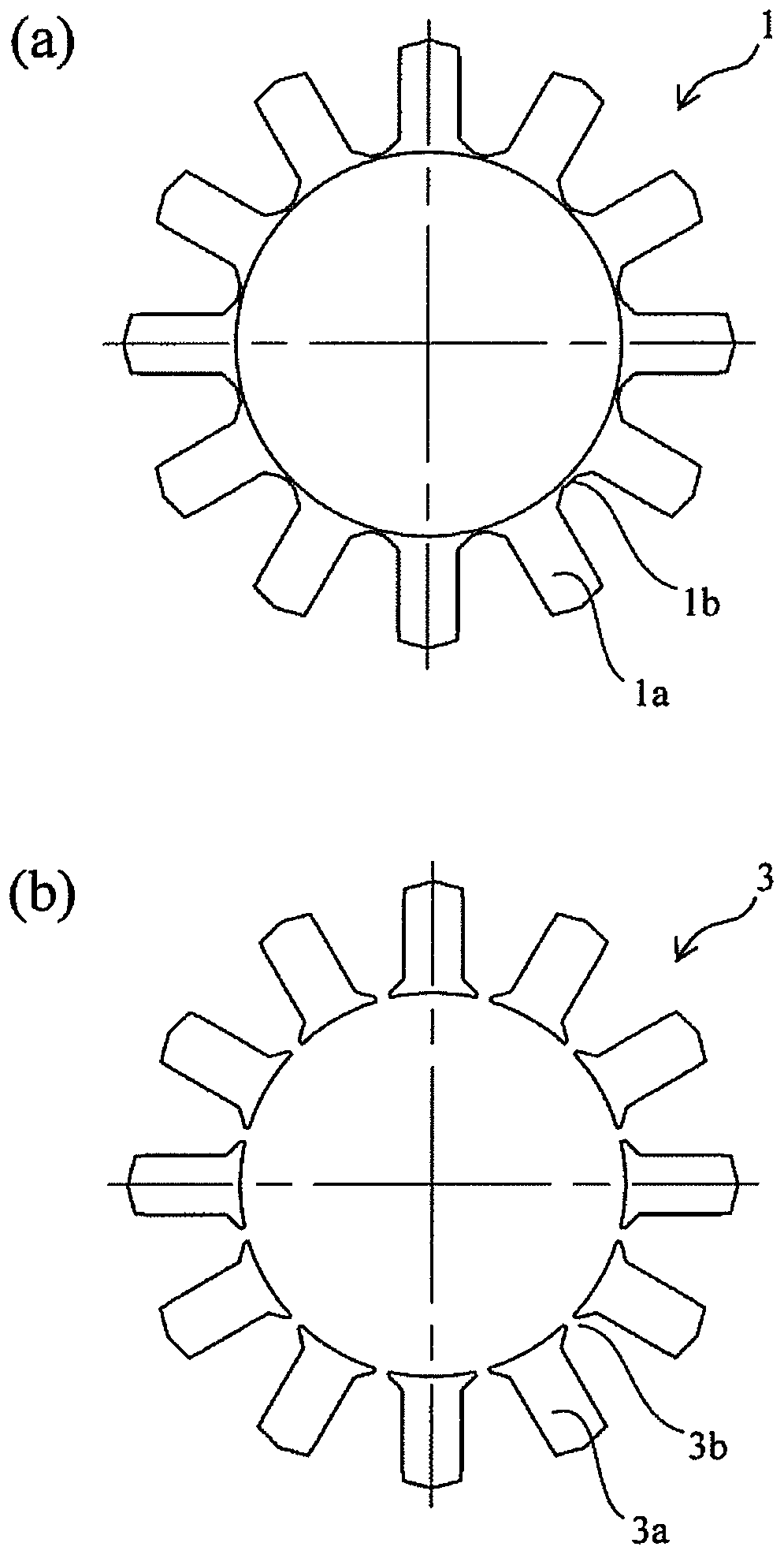

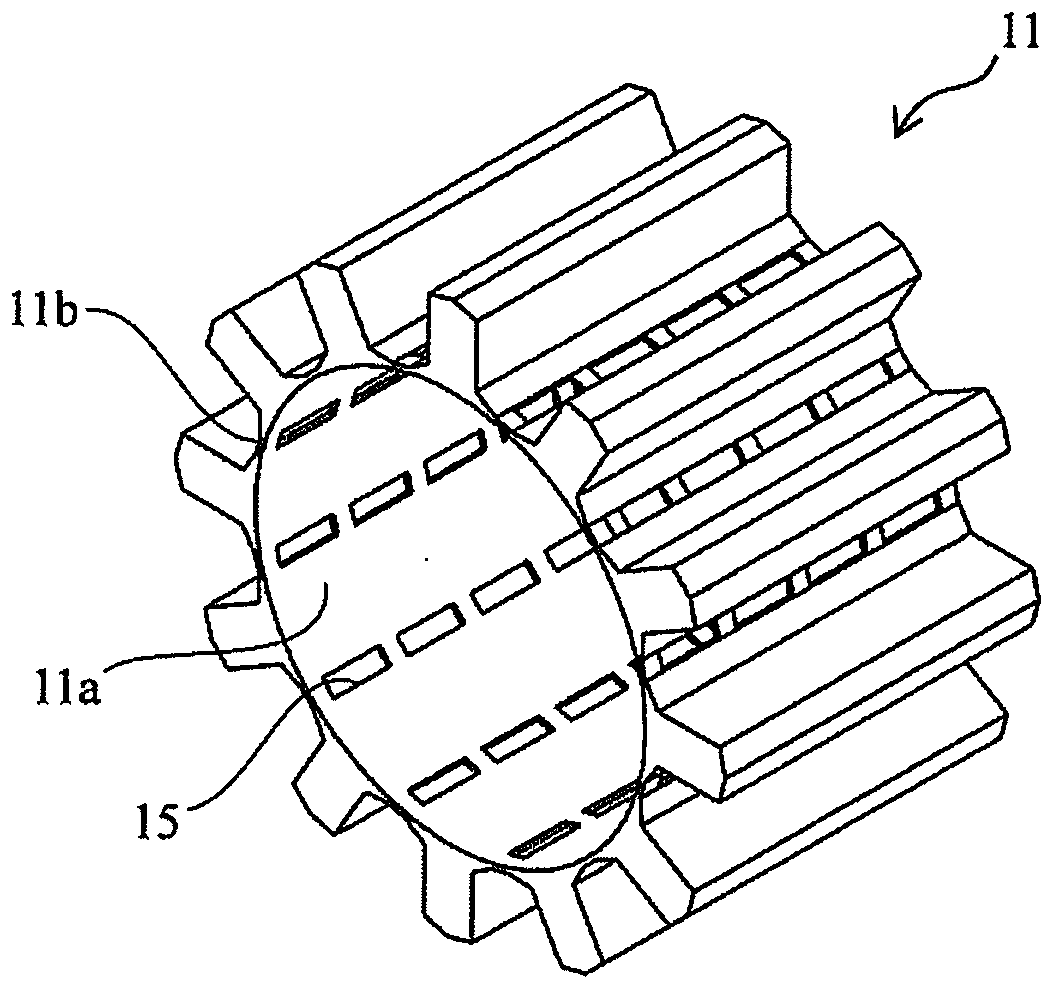

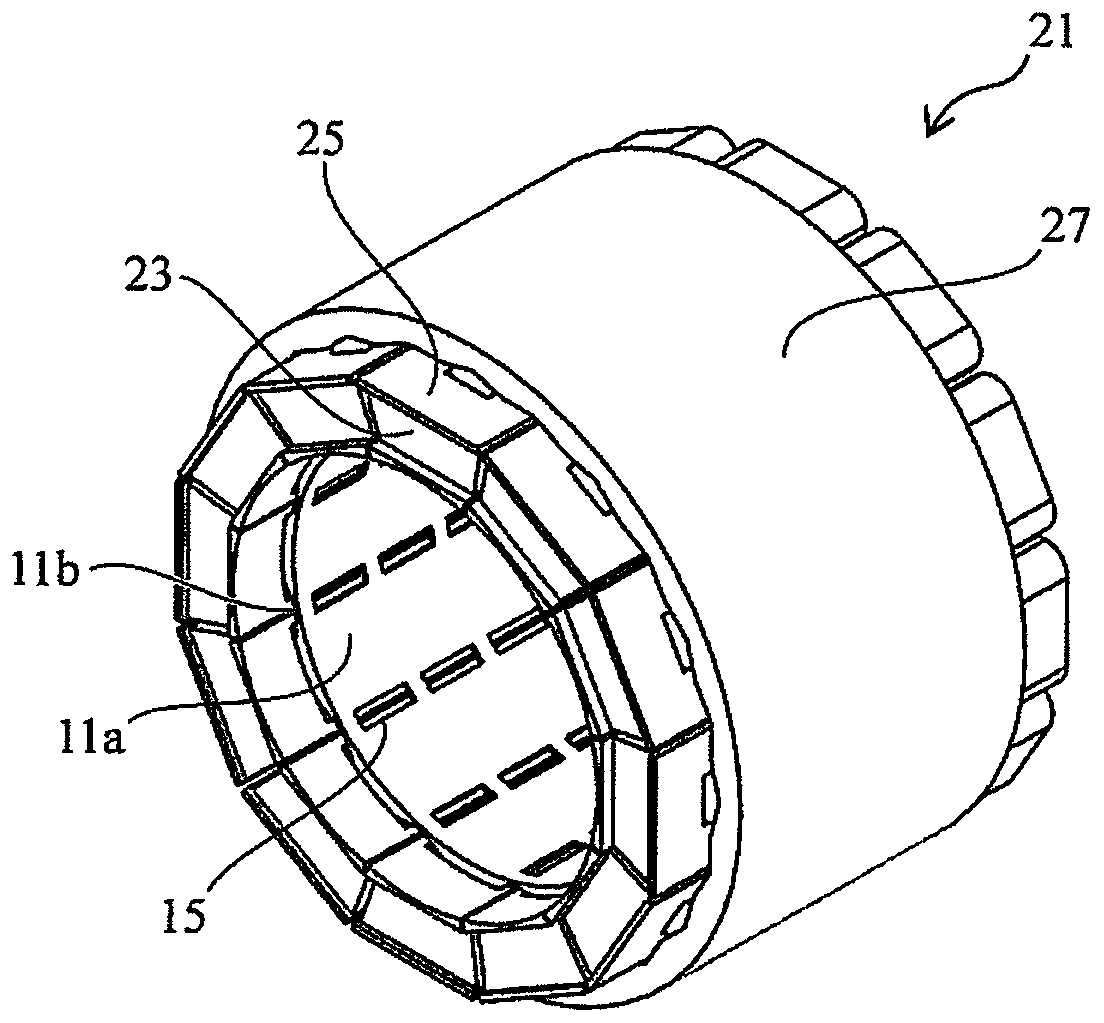

[0021] figure 1 It is an example of the core sheet which shows the iron core used for the mold structure of the motor armature (stator) which concerns on one Embodiment of this invention. figure 1 (a) is a plan view showing a configuration example of the first core sheet. figure 1 (b) is a plan view showing one configuration example of the second core sheet. figure 2 It is a perspective view showing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com