Rotors, electric motors, compressors and refrigeration and air conditioners

A rotor and gap technology, applied in the field of refrigeration and air conditioners, can solve the problems of magnetic force reduction, motor efficiency deterioration, torque reduction, etc., and achieve the effect of suppressing torque ripple and torque reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

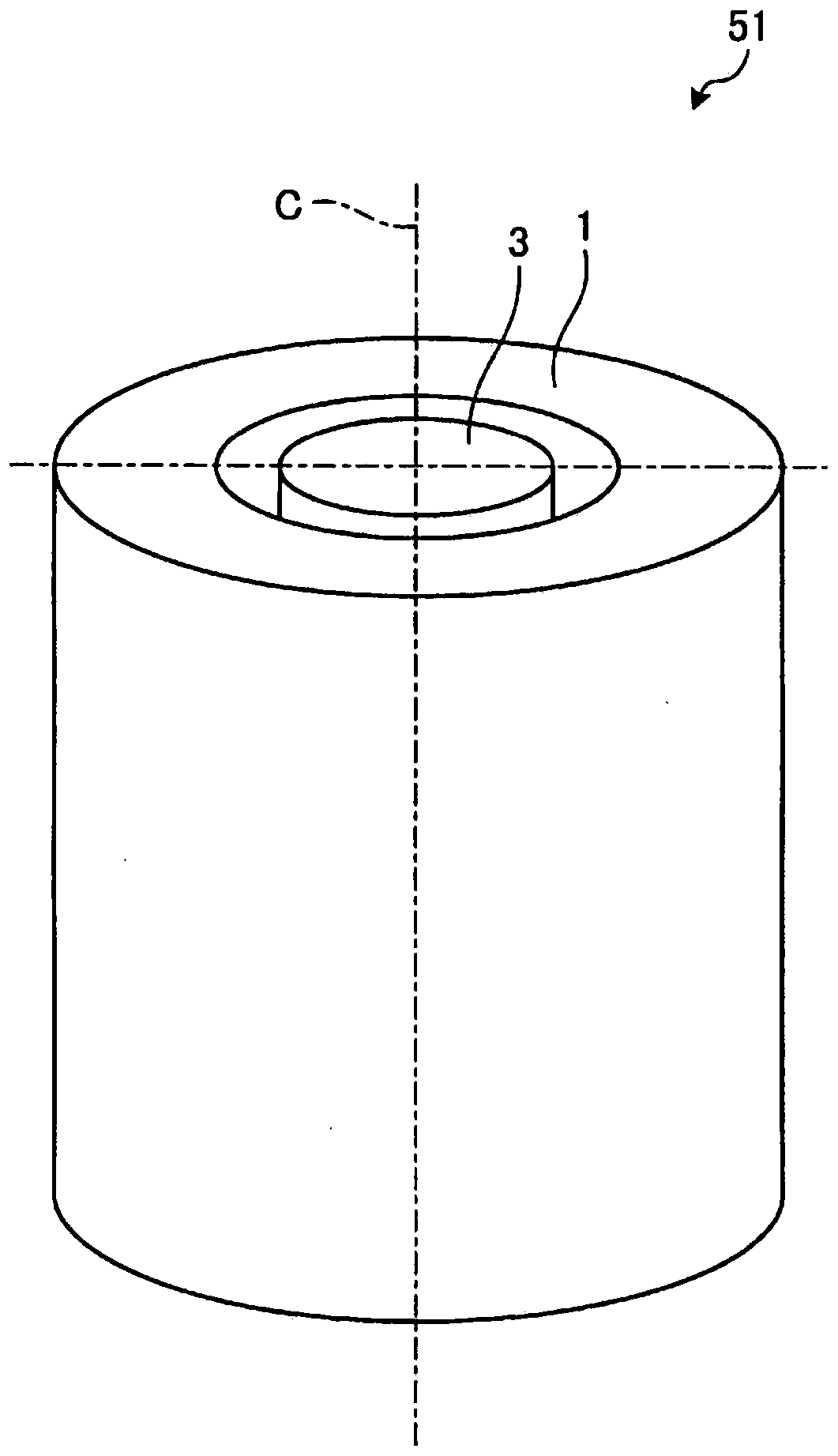

[0025] figure 1 It is a perspective view showing a schematic configuration of the motor according to Embodiment 1 of the present invention. The motor 51 includes a cylindrical stator 1 and a rotor 3 provided inside the stator 1 and rotating around a central axis C of the stator 1 .

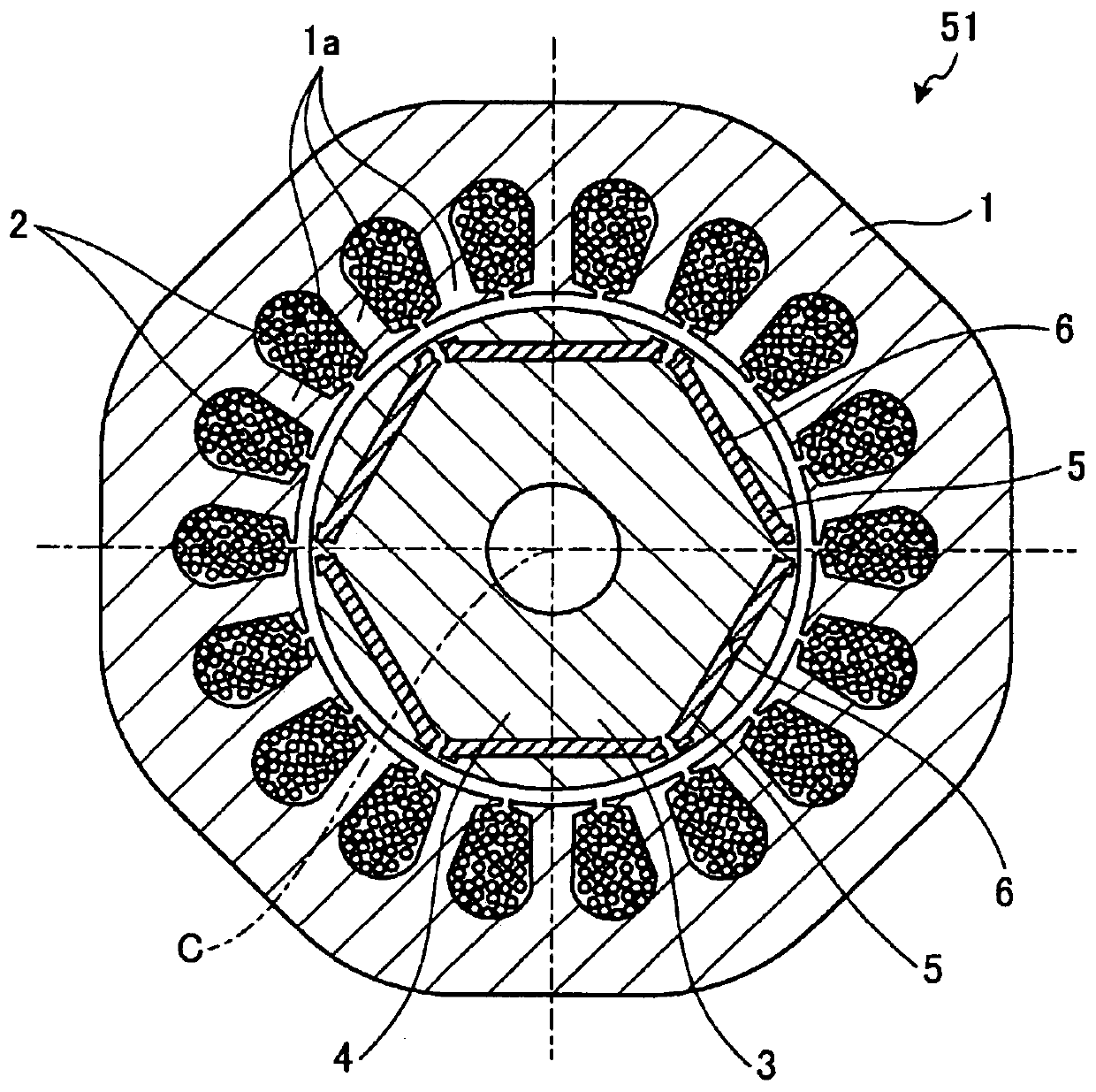

[0026] figure 2 It is a cross-sectional view of the motor 51 according to Embodiment 1 taken along a plane perpendicular to the central axis C. FIG. The stator 1 is configured by winding a winding 2 around a plurality of teeth 1 a protruding inward. The rotor 3 exhibits a cylindrical or cylindrical shape extending along the central axis C. As shown in FIG. The rotor 3 is arranged with a gap between it and the stator 1 .

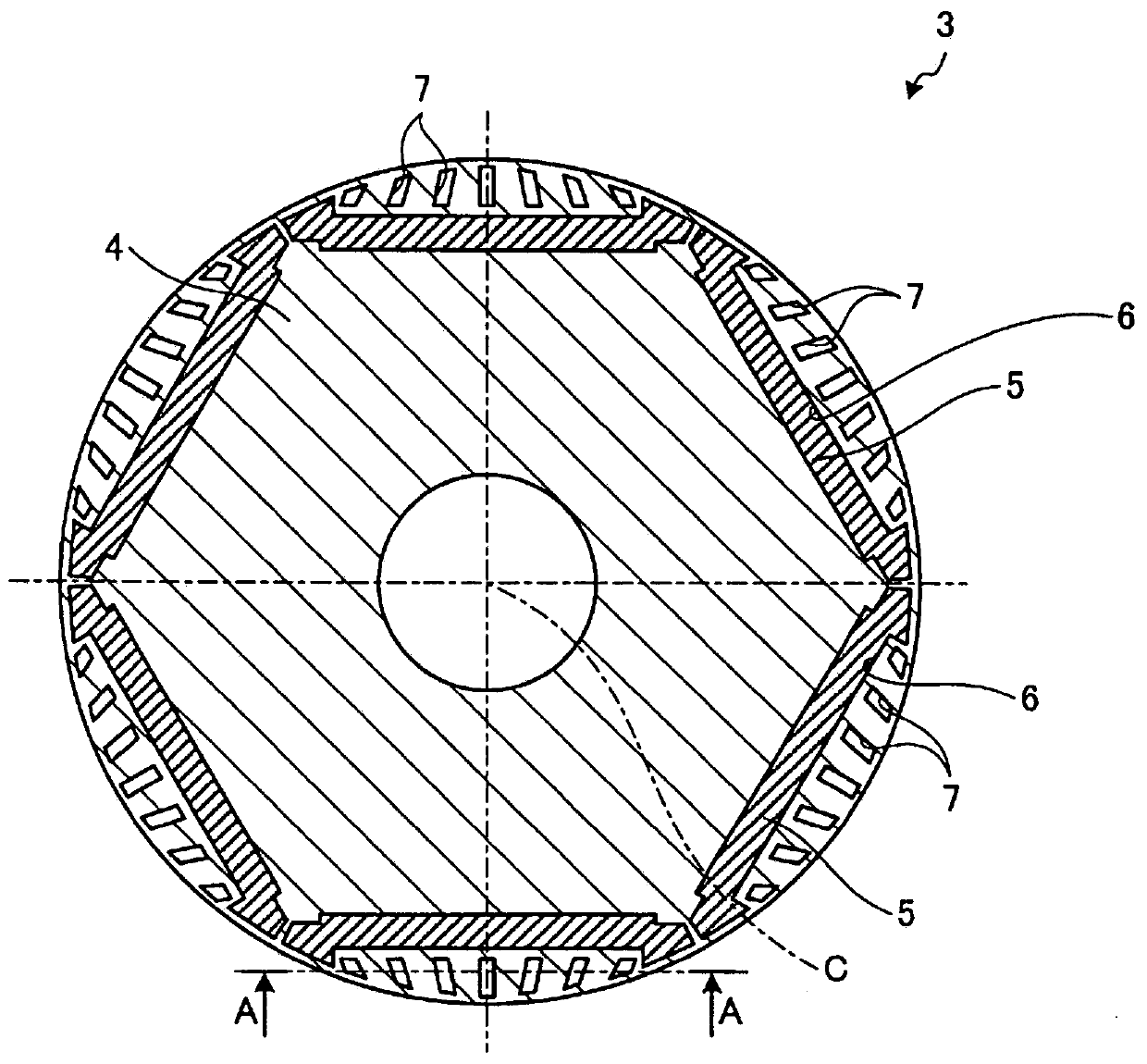

[0027] image 3 It is a cross-sectional view of the rotor 3 in Embodiment 1 taken along a plane perpendicular to the central axis C. The rotor 3 includes an iron core 4 formed by laminating a plurality of electromagnetic steel sheets in a direction along the central axis C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com