Connector for hermetic compressors

A technology of hermetic compressors and compressor shells, which is applied to the components of pumping devices for elastic fluids, liquid variable displacement machines, mechanical equipment, etc., and can solve the problems of complex manufacturing and assembly processes, expensive, etc. Achieve the effect of economical production process and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described according to the accompanying drawings.

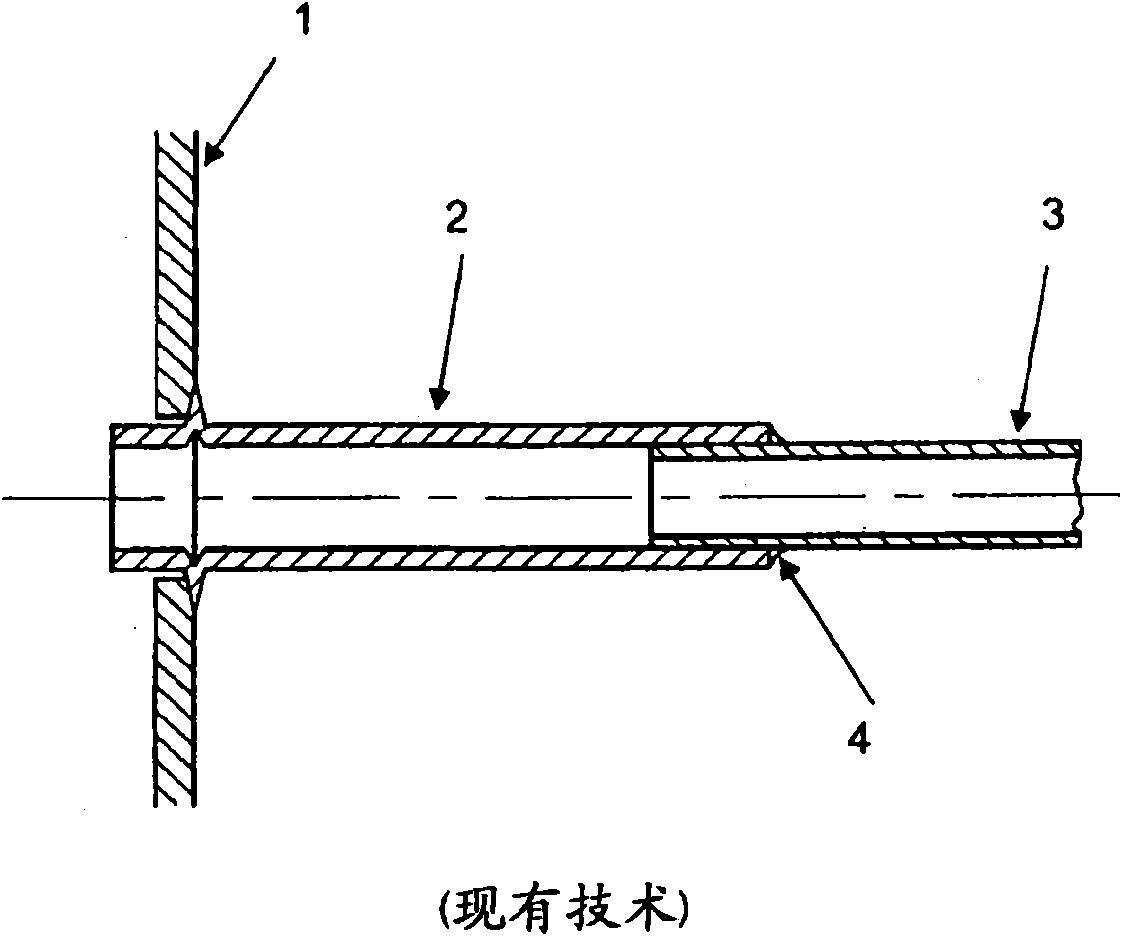

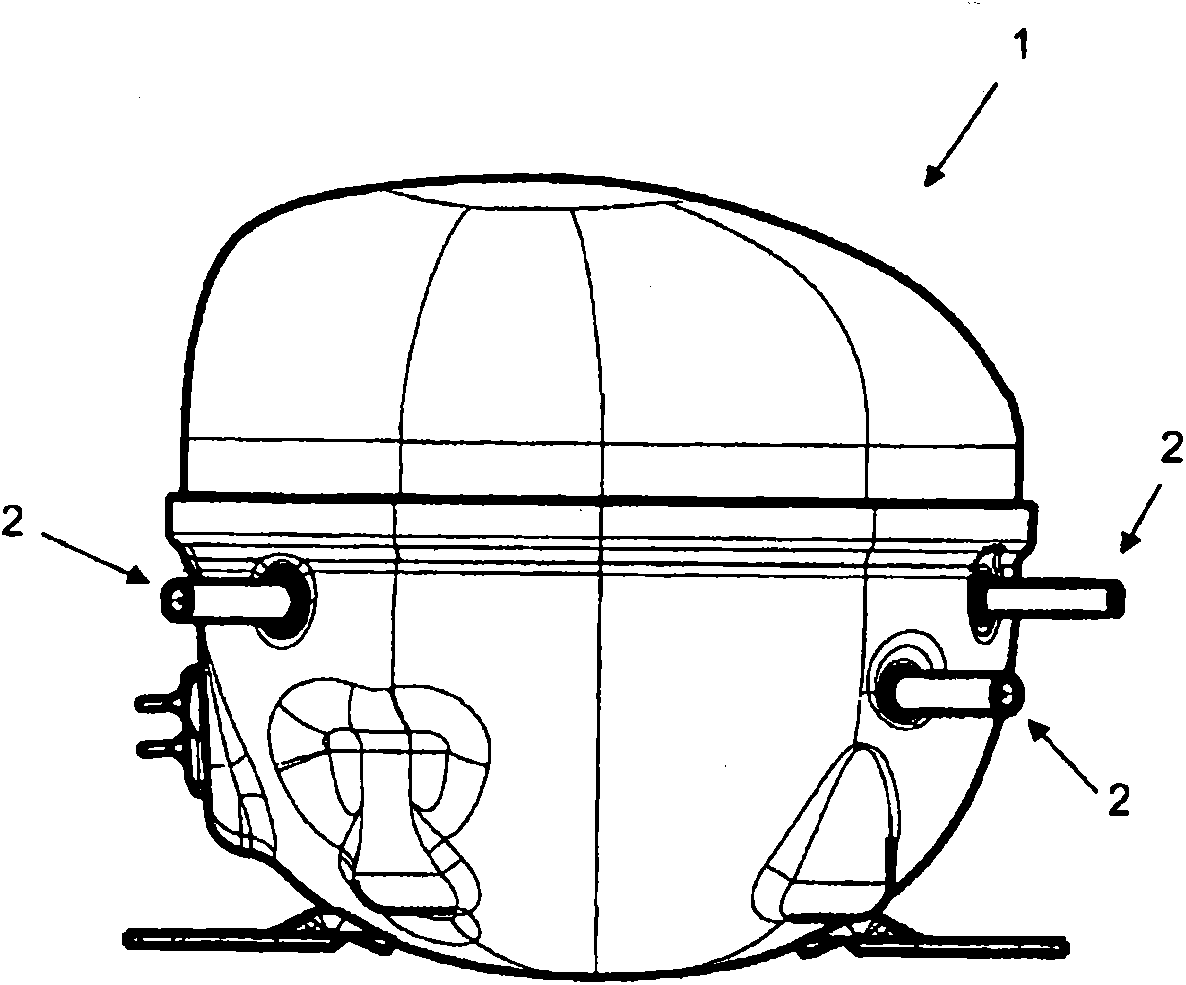

[0024] figure 1 Shown is a connecting pipe 2, commonly used in the present case of the prior art, for connecting the casing 1 of the compressor to any pipe 3, which may be a process valve or an evaporating and / or A hermetic compressor is installed in the tubes of a condensing system, refrigerator or freezer. This is a single part typically made of a single material, usually copper, having one end connected to the compressor housing 1 and the other end connected to the system pipe 3 .

[0025] Usually, connecting the connecting pipe 2 to the system pipe 3 is done by figure 1 The brazing part 4 indicated in the mark is implemented.

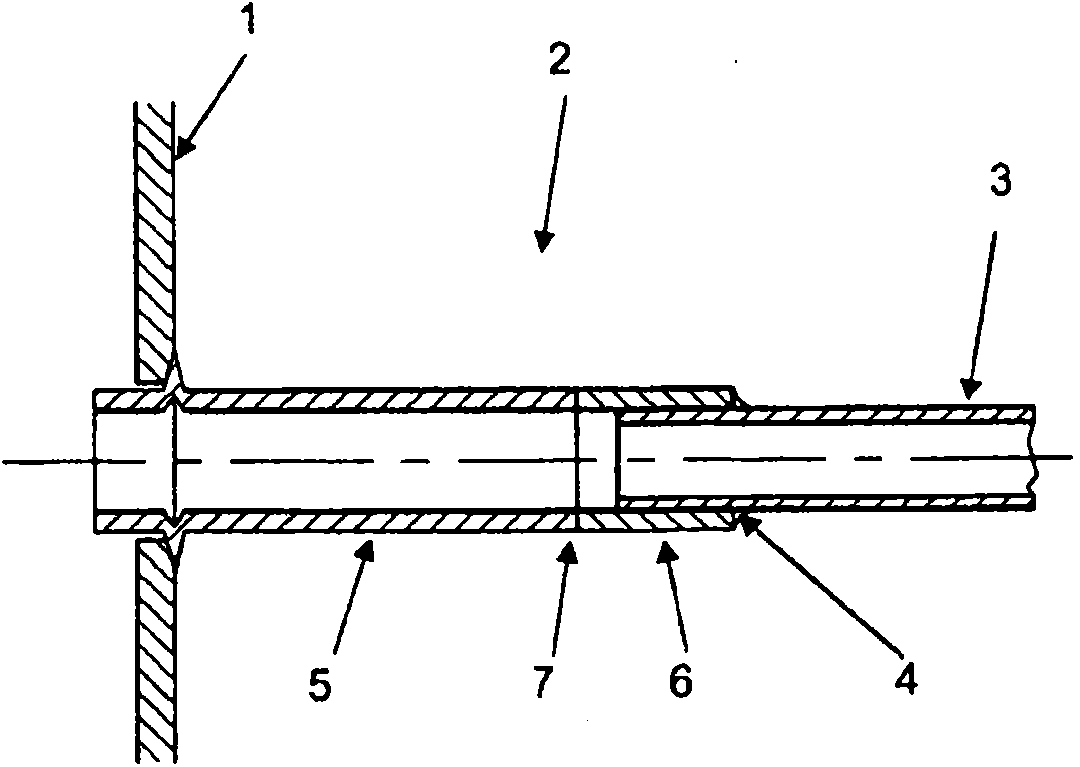

[0026] The preferred embodiment proposed by the present invention sees in detail figure 2 , wherein the joint 2 is composed of two tubular parts 5 and 6, the first part 5 of the connecting pipe 2 is made of one material, and the second part 6 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com