Fusion sealing equipment using laser

A technology of sealing equipment and lasers, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of lengthening paths, reducing production efficiency, and prolonging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

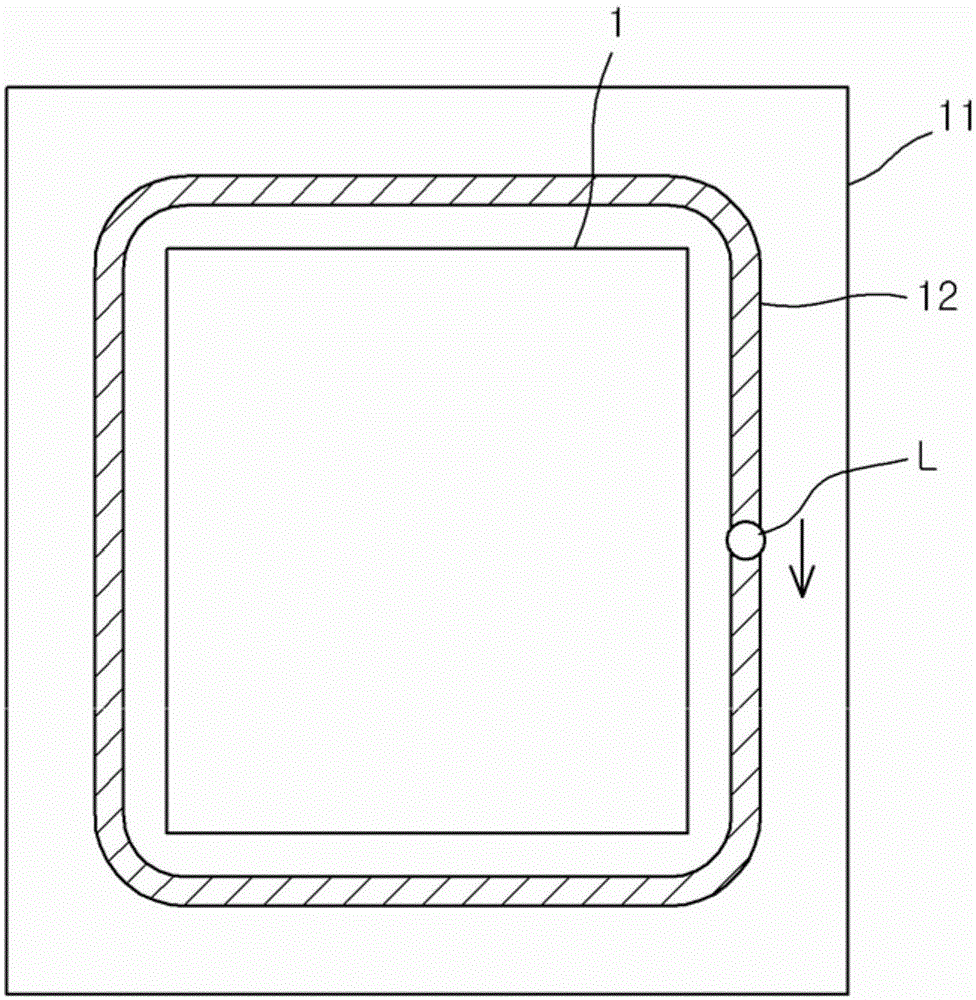

[0019] Hereinafter, an exemplary embodiment of a fusion sealing apparatus using a laser according to the present invention will be described in detail with reference to the accompanying drawings.

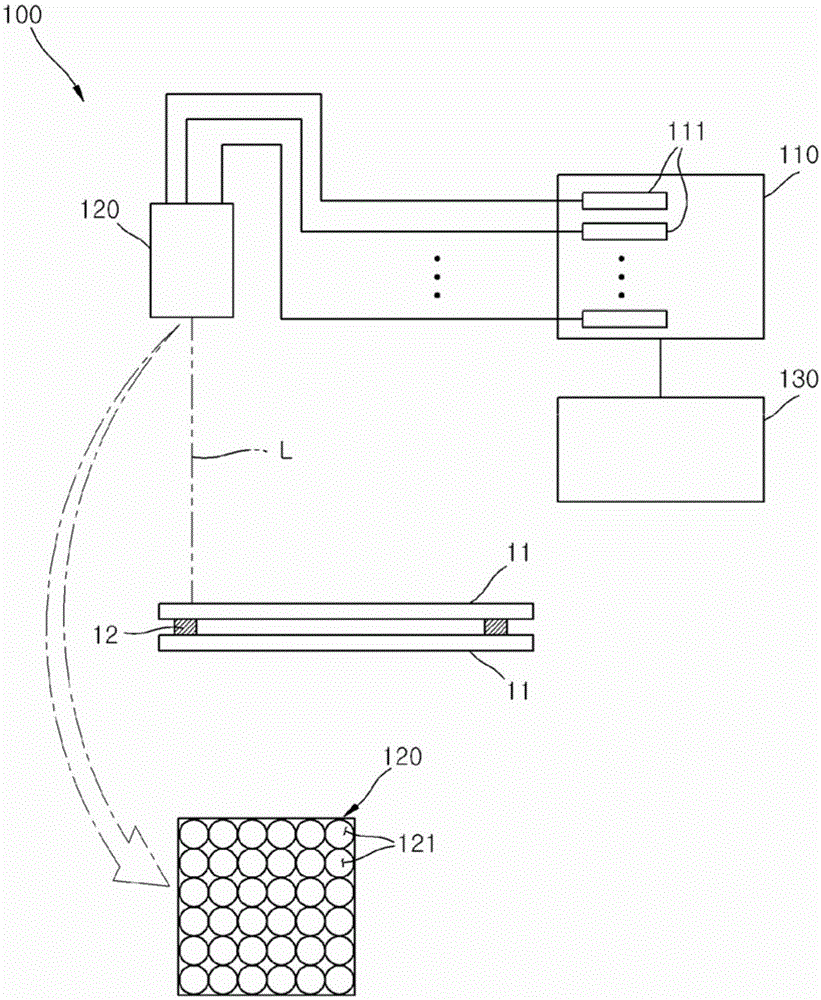

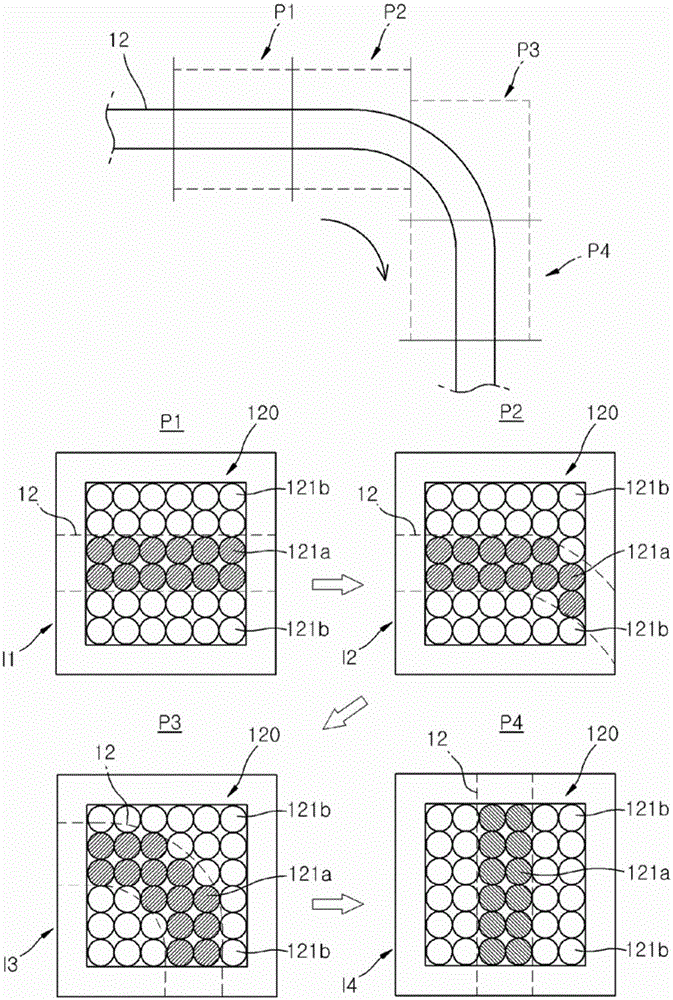

[0020] figure 2 is a diagram schematically showing a fusion sealing apparatus using a laser according to an exemplary embodiment, and image 3 is for illustration figure 2 Diagram of the fusion sealing process using a laser fusion sealing device.

[0021] refer to figure 2 and image 3 , the fusion sealing apparatus 100 using a laser according to an exemplary embodiment to emit a laser beam propagating through some optical fibers selected from a plurality of optical fibers to a frit to perform sealing with the frit. The fusion sealing apparatus 100 includes a laser output unit 110 , an optical fiber bundle unit 120 , a transport unit, and a controller 130 .

[0022] The fusion sealing apparatus 100 using a laser according to an exemplary embodiment will be described as an ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com