Method for manufacturing waiting compartment of rail train group with length exceeding station

A technology for rail trains and carriages, which is applied in the direction of railway car body, railway car body parts, transportation and packaging, etc., and can solve problems such as hindering passengers from getting on and off, blocking small doors, and not designing passenger trains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] 34. Rail trains are composed of subway trains:

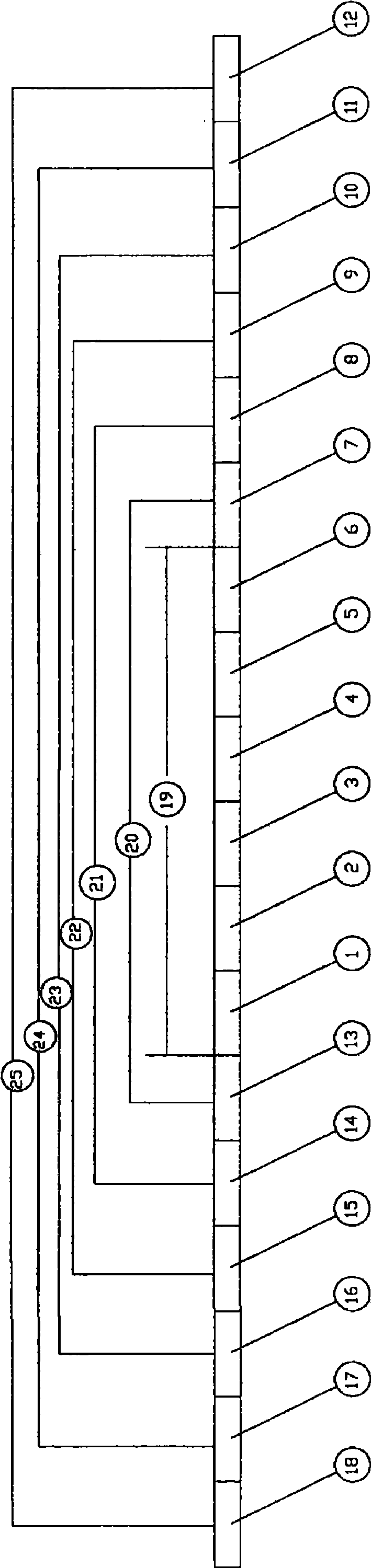

[0058] Such as Picture 1-1 , such as a total of 26 stations on the line: 1.2.3.4.5.6.7.8.9.10.11.12.13.14.15.16.17.18.19.20.21.23.24.25.26 stations, the bus interval distribution structure; 6 intervals: 2--8 White: -9---11 blue; -12-14 blue; -15---17 green; -18-20 yellow; -21-23 orange; 24---26 red, abbreviated as 8 white —3 Blue—3 Green—3 Green—3 Yellow—3 Orange—24—26 Red;

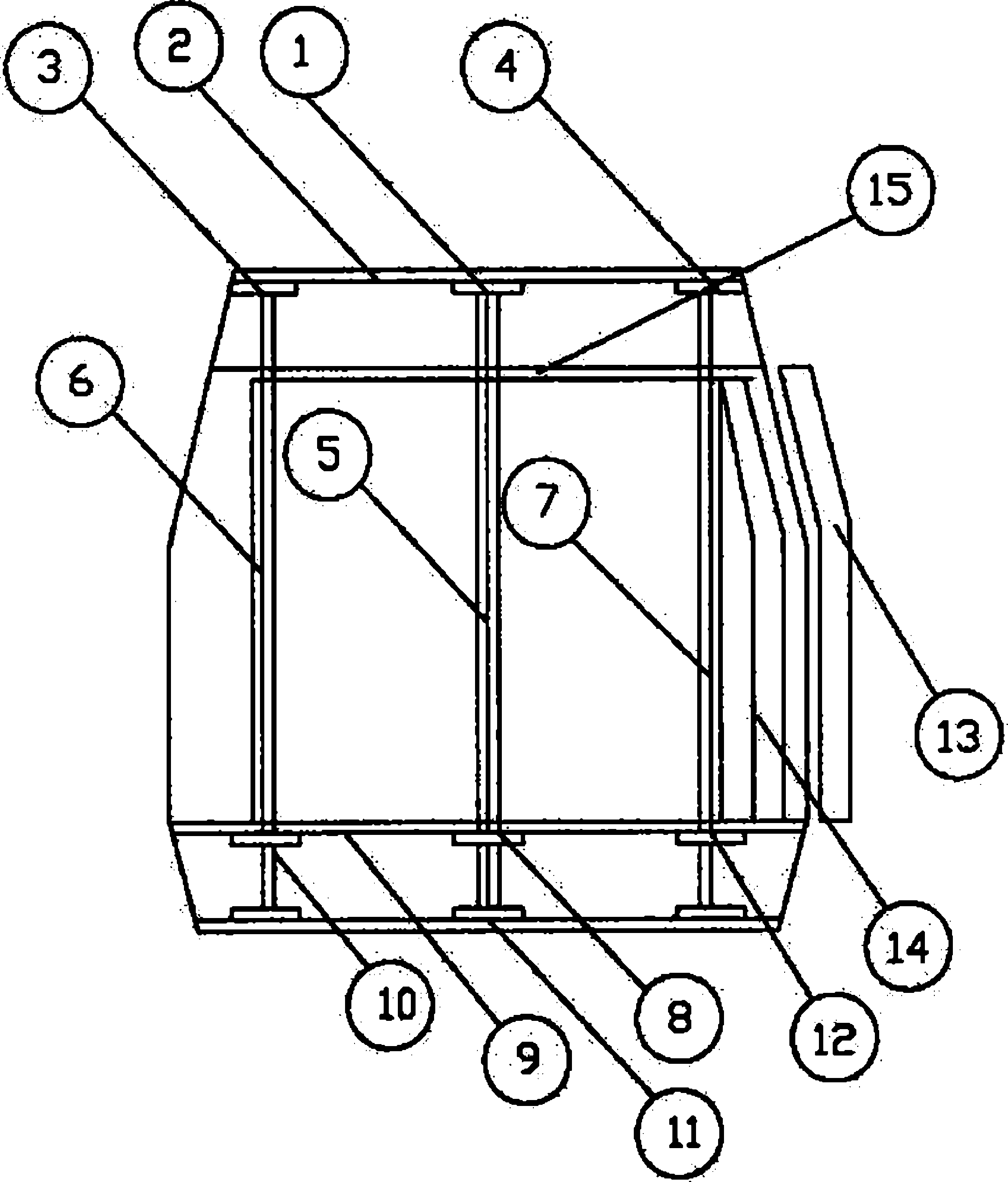

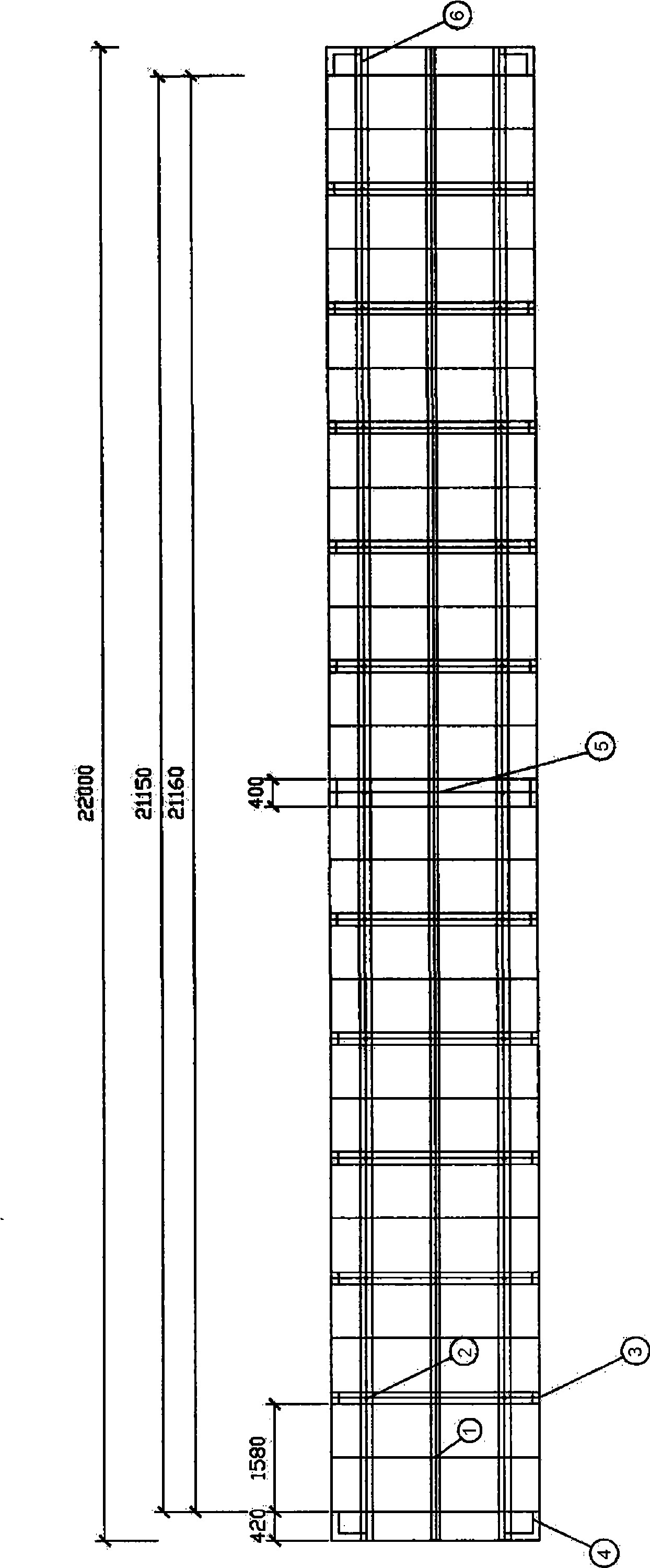

[0059] (1) Subway train marshalling process: rail trains take the subway car marshalling as a row, because the length of the rail train carriages is lengthened, it is too dark in the tunnel wall outside the two ends of the subway platform beyond the equal length of the carriages without side doors, so that passengers have trouble For a sense of security, it is necessary to add advertising light boxes on the tunnel walls on both sides of the platform. The length corresponds to the same length, which is the track length of the U-turn turnout requir...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap