Siphon acceleration jet type siphon closestool

A spray-type and siphon technology, which is applied to flushing equipment with water tanks, flushing toilets, water supply devices, etc., can solve the problems that siphon pipes cannot quickly form siphons, waste of water resources, and poor flushing performance on the inner wall of toilets and urinals, etc. , to achieve good sewage discharge effect, save water, and ensure the effect of flushing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

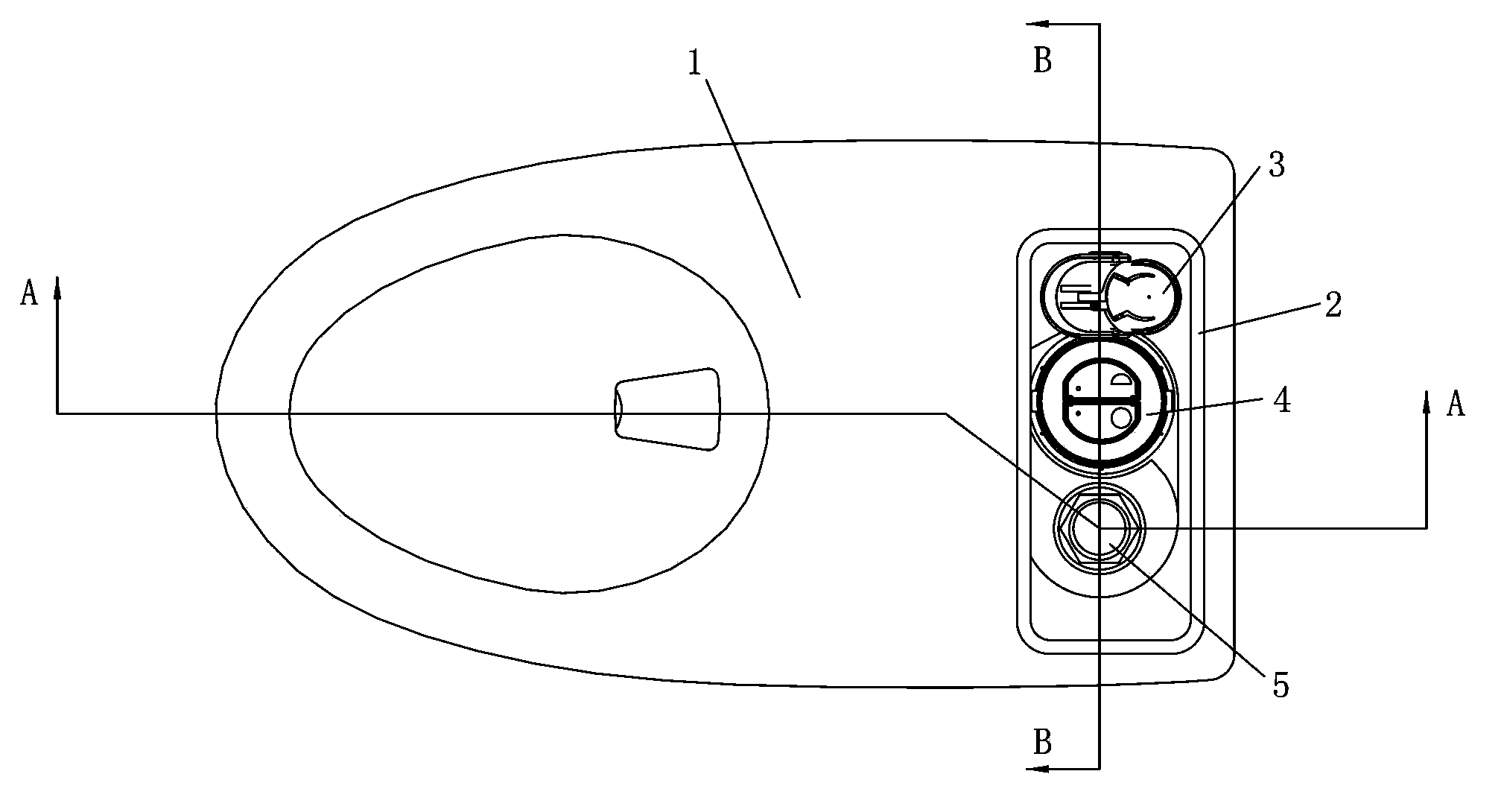

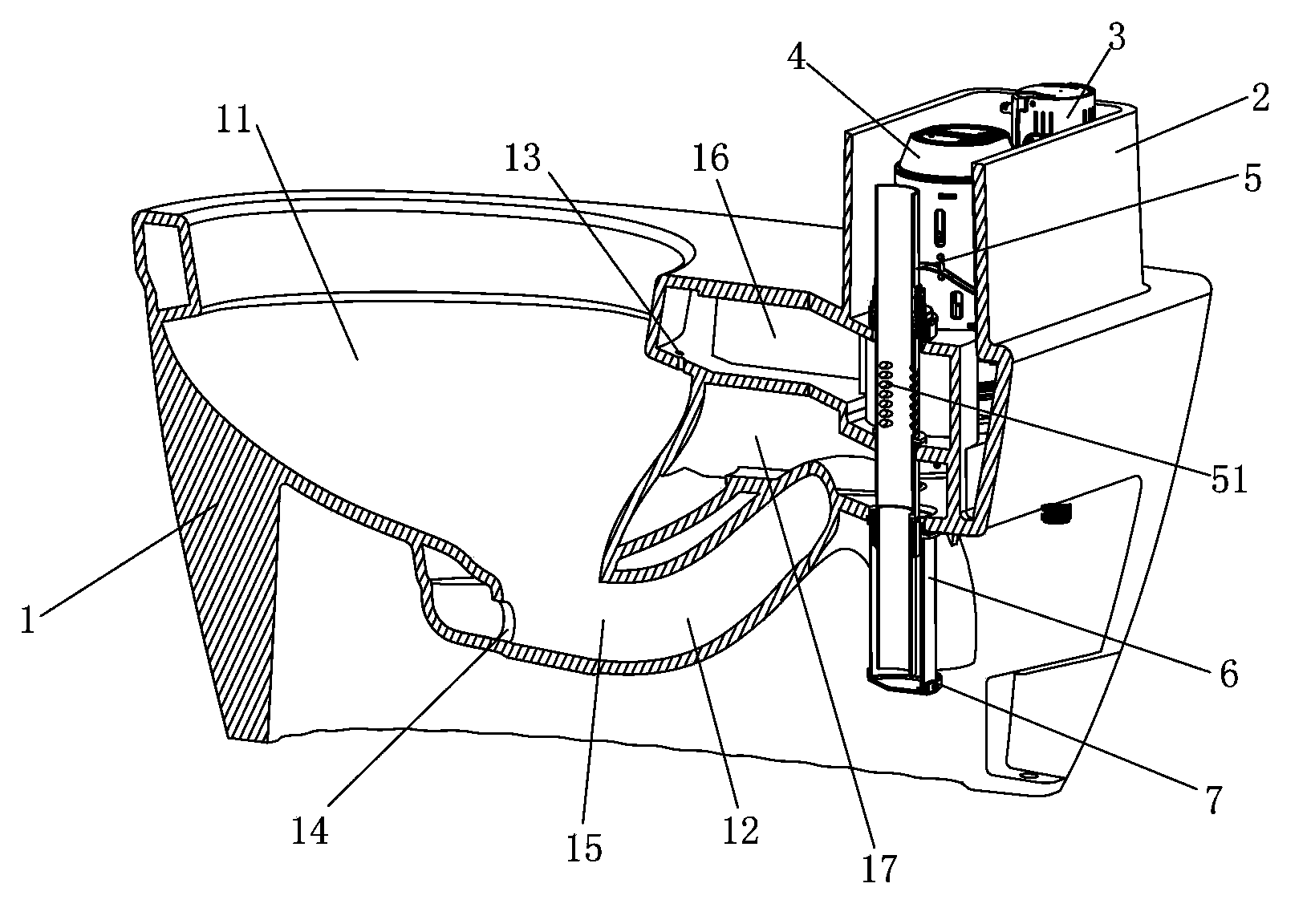

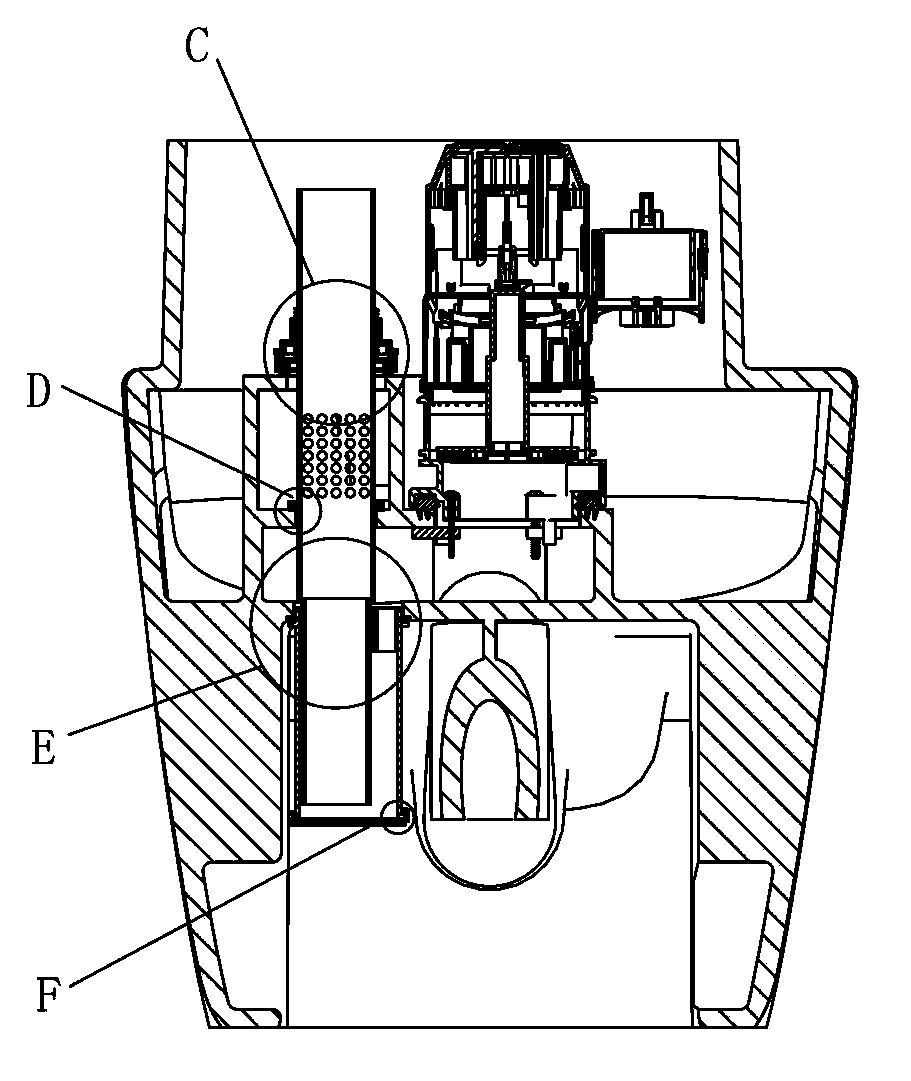

[0030] See Figure 1-Figure 7 As shown, a siphon-accelerated jet siphon toilet of the present invention includes a toilet body 1 and a first water tank 2, the first water tank 2 is integrally formed with the toilet body 1, and the first water tank 2 is equipped with a water inlet valve 3, a second A drain valve 4 and an overflow pipe 5, the water inlet valve 3 is connected to the water supply system, the top of the overflow pipe 5 is open, and is located in the first water tank, and is higher than the working water level of the first water tank 2; the toilet body 1 is provided with a urinal 11 and a siphon pipe 12, a plurality of flushing holes 13 are distributed around the top of the urinal of the toilet body 1, and the bottom of the urinal of the toilet body 1 is provided with a jet port 14, and the jet port 14 is aligned with the inlet 15 of the siphon pipe 12 , the other end of the siphon pipe 12 is a sewage outlet (not shown in the figure), which is used to connect to the...

Embodiment 2

[0037] See Figure 8 , Figure 9 As shown, a siphon-accelerated jet siphon toilet of the present invention differs from Embodiment 1 in that its flushing water delivery pipeline is supplied with water by a second water tank (not shown in the figure), and a second water tank is equipped with a As for the second drain valve, the inlet of the flushing water delivery pipeline communicates with the drain port of the second drain valve. Here, the first drain valve 4 and the second drain valve can be connected by a linkage mechanism to realize linkage control of the first drain valve 4 and the second drain valve. In this way, when the first drain valve 4 connected to the spray water delivery pipeline 17 is opened, the second drain valve can be opened at the same time or not at the same time, so that the flushing water delivery pipeline enters water to flush the urinal inner wall of the toilet body 1 .

[0038] After adopting the structure shown in the second embodiment, as in the f...

Embodiment 3

[0041] See Figure 10 , Figure 11 As shown, a siphon-accelerated jet siphon toilet of the present invention differs from the first embodiment above in that the communication pipe 8 is a pipeline that is independently arranged and integrated with the toilet body, and the top of the communication pipe 8 opening, and is also located in the first water tank 2, and its top opening is higher than the water level of the first water tank 2 (the water in the first water tank can overflow through the top opening of the communication pipe 8), and the bottom end of the communication pipe 8 is upward Bending, the bottom is bent into a U shape, thereby forming a water seal structure, the top of the upward bending part of the connecting pipe 8 has a port 82, the connecting pipe 8 communicates with the jet water delivery pipeline 17 through the port 82; The side wall of the middle section of the pipe 8 is provided with a water outlet hole 81 (the water outlet hole 81 is located on the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com