Anti-loosening mechanism for quick release component

An anti-dropping and wrench technology, applied in the connection of connecting components, mechanical equipment, rods, etc., can solve the problems of quick release group failure, wrench collision, wrench loosening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

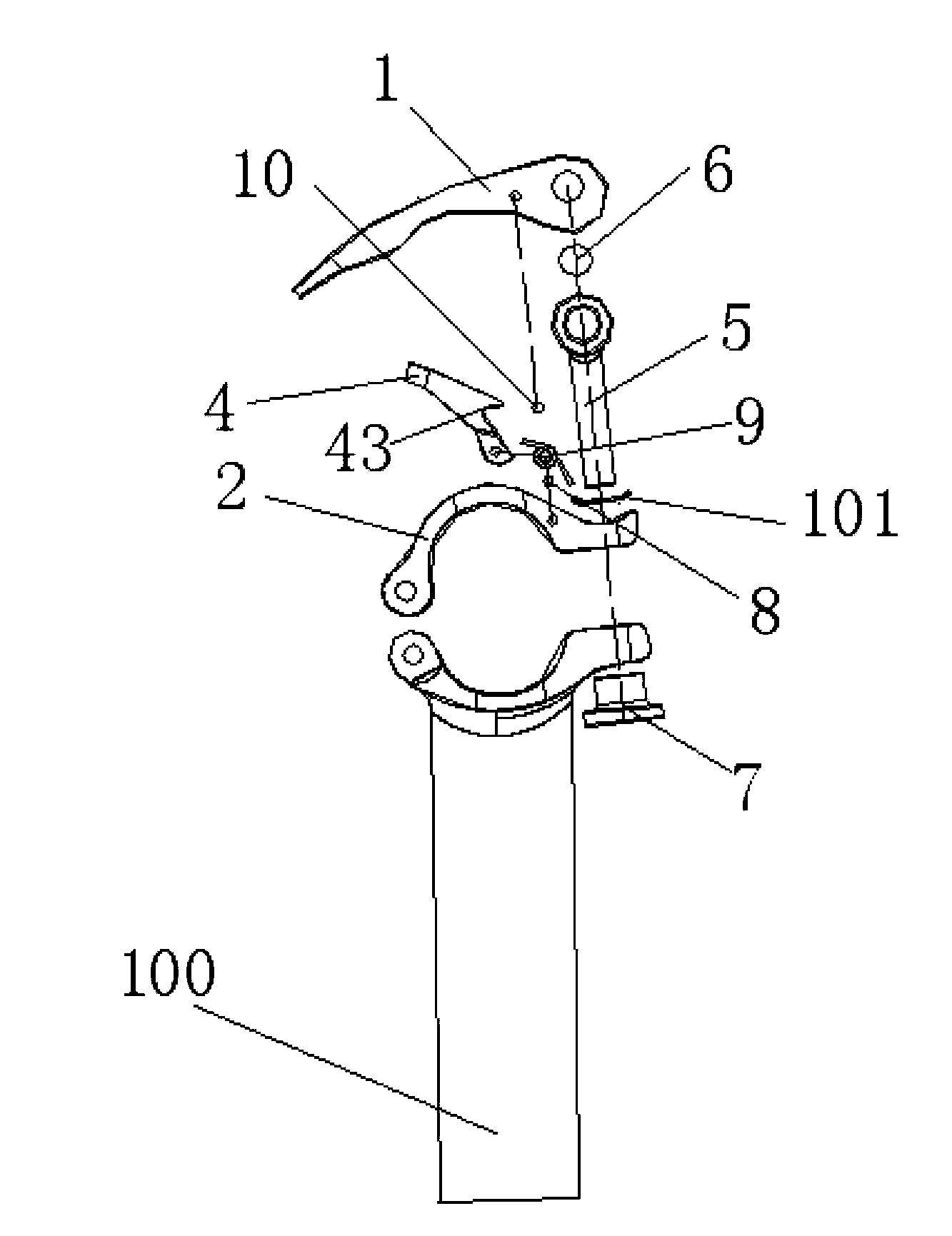

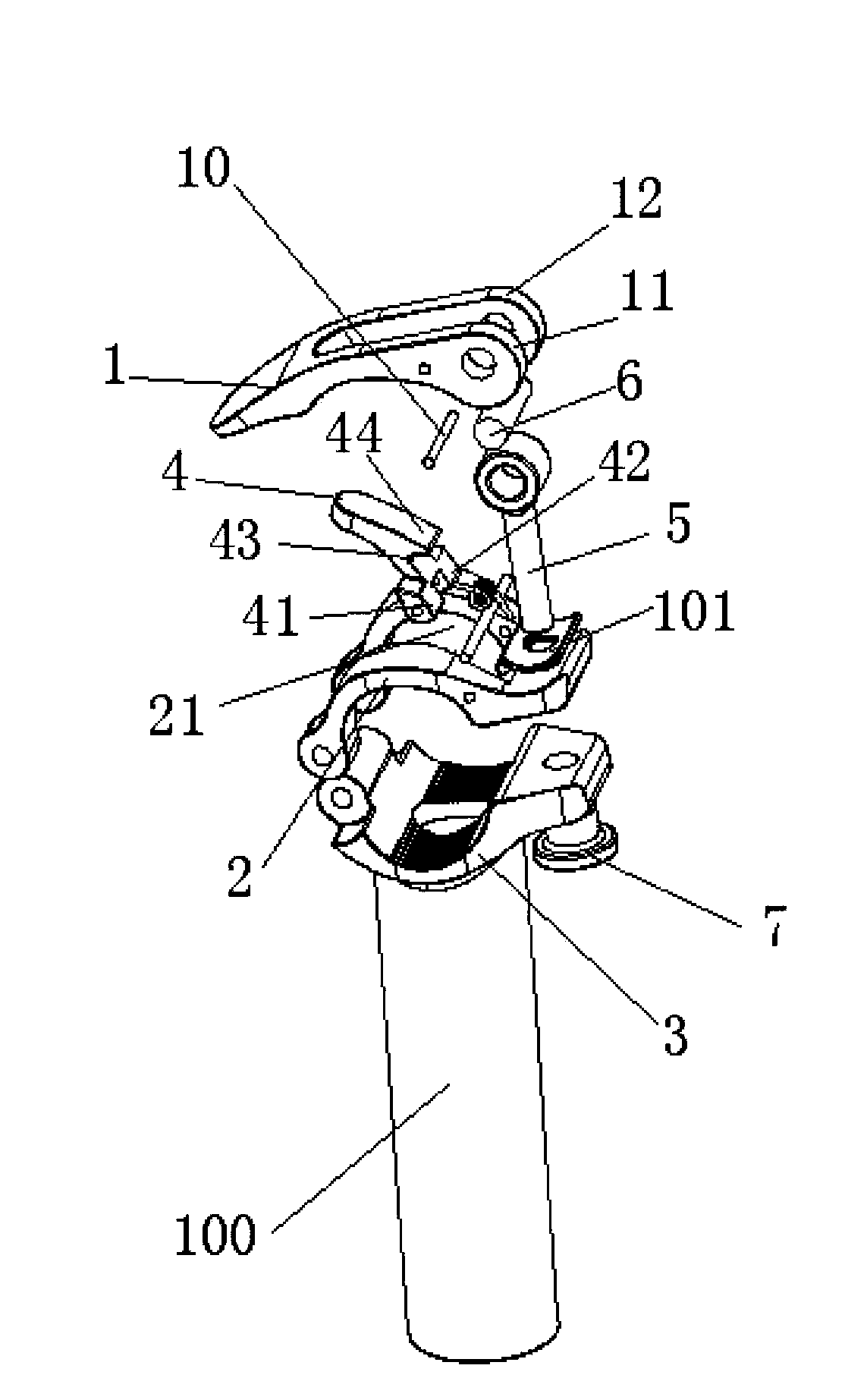

[0017] to combine figure 1 , figure 2 with image 3 , as described in detail below:

[0018] An anti-off mechanism for a quick-release group, installed between the upper wrench 1 and the upper cover 2 of the quick-release group, the quick-release group includes a lower cover 3 that is fixed to one side of the upper cover 2 and moves through the upper cover 2 After the upper cover plate 2 and the other side of the lower cover plate 3, screw a bolt 5 with a nut 7 and a rotating shaft 6 that passes through the root of the bolt 5. The ends of the wrench form a pair of supporting feet 11 with U-shaped openings. 12. The ends of the pair of supporting feet 11 and 12 are respectively sleeved on the two ends of the rotating shaft 6, and the ends of the pair of supporting feet 11 and 12 respectively have eccentric edges. Wrench 4, the anti-off wrench 4 forms a pair of anti-off supporting feet 41, 42 side by side. A clamping shaft 10 is fixed between the supporting legs 11 and 12, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com