Clutch Controller

一种离合器控制、离合器的技术,应用在离合器、机械驱动离合器、相互啮合的离合器等方向,能够解决离合器旋转速度一致困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

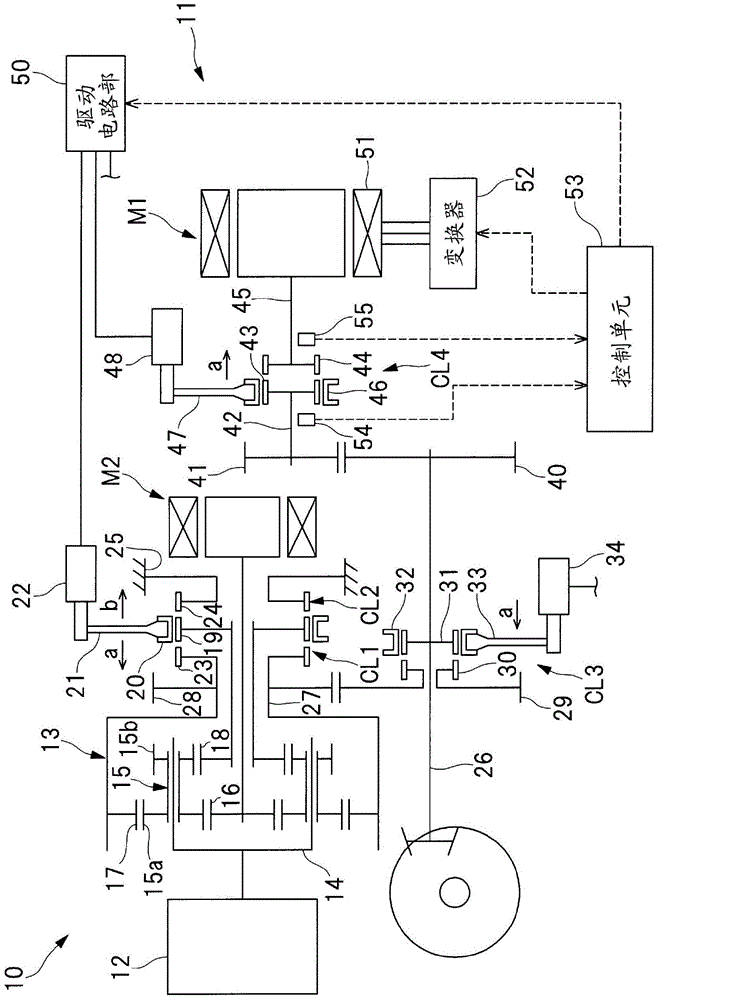

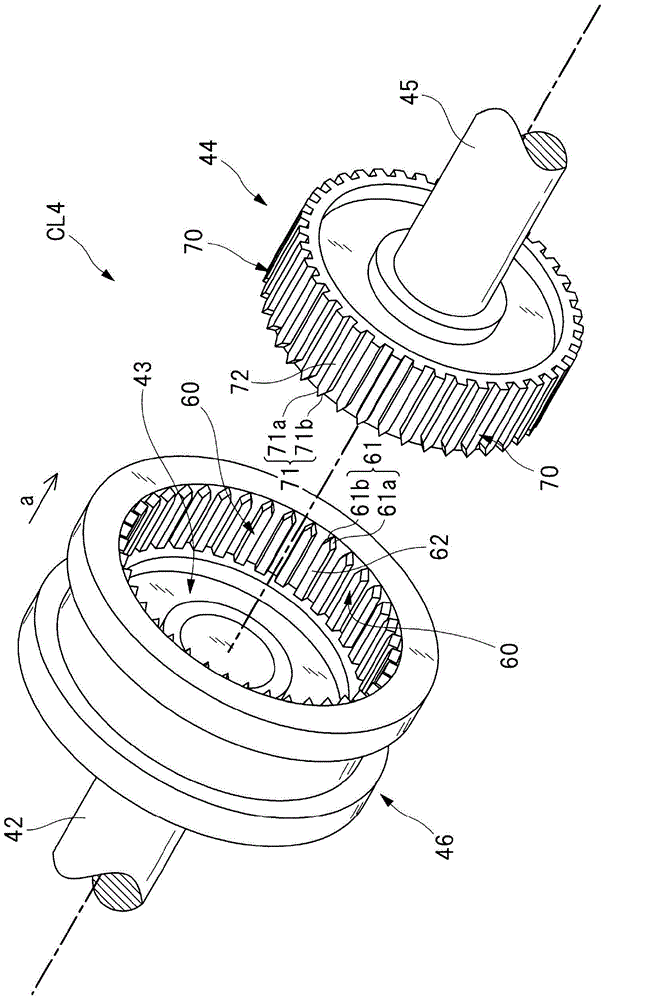

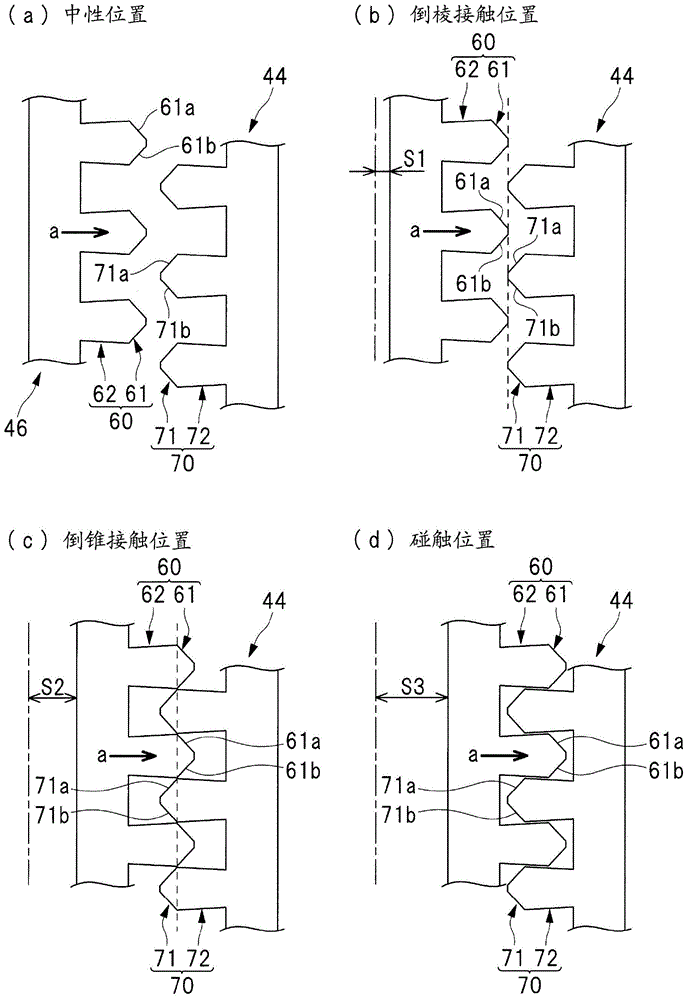

[0036] Hereinafter, embodiments of the present invention will be described in detail based on the drawings. figure 1 It is a schematic diagram showing a part of the powertrain 10 mounted on the hybrid vehicle and its control system. In this power train 10, a clutch control device 11 as an embodiment of the present invention is incorporated. Such as figure 1 As shown, in the power train 10, an engine 12, a first motor generator M1, and a second motor generator M2 are provided as power sources. In addition, in the power train 10, a clutch CL1, a clutch CL2, a clutch CL3, and a clutch CL4 are provided as meshing clutches. The clutches CL1 to CL4 are dog clutches, that is, meshing clutches that do not have a rotation synchronization mechanism such as a synchronizer ring.

[0037] Between the engine 12 and the motor generator M2, there is provided a power splitting mechanism 13 that splits the engine power to the driving wheels and the motor generator M2. The power split mechanism 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com