Upper die structure

The technology of a balance block and a body is applied in the field of the upper mold provided with the balance block, which can solve the problems of reducing the upper mold and suppressing deformation, uneven pressure distribution, and large area of the upper mold, and achieves pressure balance, good sharing effect and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This preferred embodiment provides an upper mold structure, including an upper mold body and a plurality of balance weights. A plurality of balance weights are respectively arranged at the edge of the bottom surface of the upper mold body, and are arranged symmetrically with respect to the center of gravity of the upper mold body.

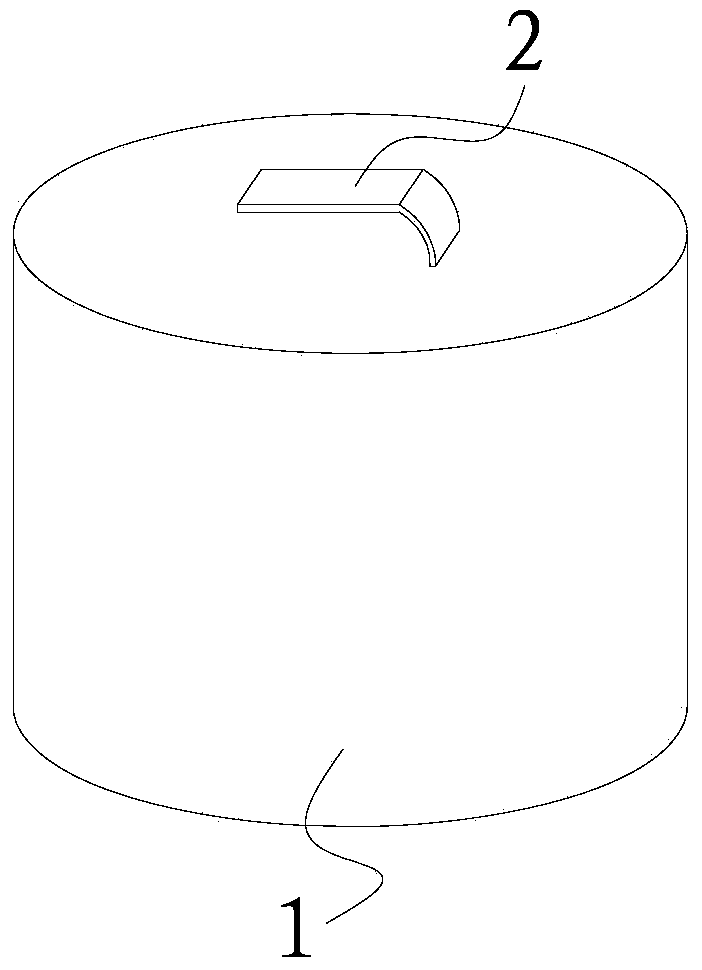

[0024] Such as figure 1 As shown, the balance weight 1 is a columnar body with a connecting portion 2 arranged on the top end. The balance weight 1 is movably connected with the upper mold body through the connecting part 2 .

[0025] During use, select the balance block 1 whose height is the same as the thickness of the workpiece to share part of the pressure on the upper die body and avoid deformation of the workpiece.

[0026] When processing a series of workpieces, the thickness of the workpieces may be different, and the required height of the balance weight 1 is also different. The balance weight 1 is movably connected with the uppe...

Embodiment 2

[0028] This preferred embodiment provides an upper mold structure, which is basically the same as the first preferred embodiment. A plurality of balance weights are arranged at the edge of the bottom surface of the upper mold body of the upper mold structure.

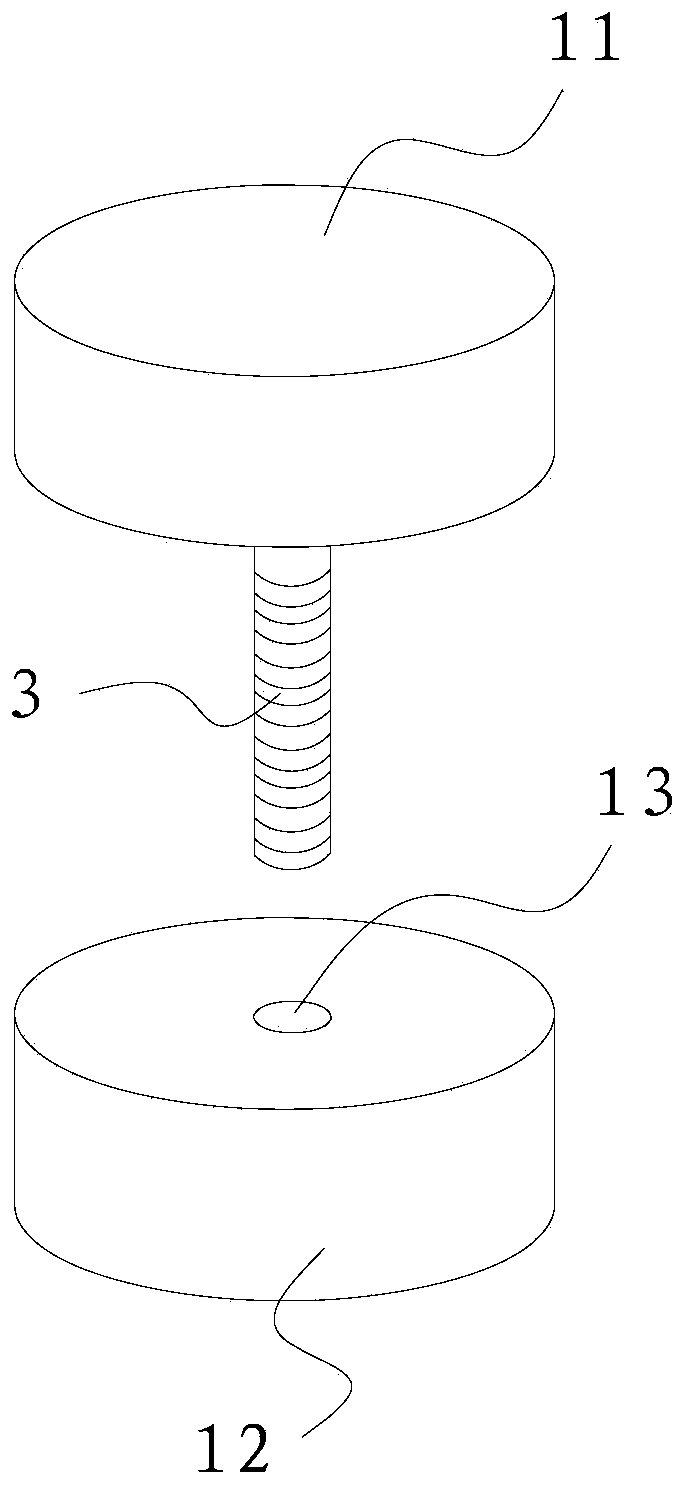

[0029] The difference is that: if figure 2 As shown, the balance block 1 includes a fixed block 11 and a movable block 12; the fixed block 11 is provided with a screw 3, and the middle part of the movable block 12 is provided with a screw hole 13; the movable block 12 can move up and down along the screw 3. A detachable pressure sensor is arranged on the bottom surface of the upper mold body.

[0030] During use, the fixed block 11 is fixed at the edge of the bottom surface of the upper mold body. Then rotate the movable block 12 to allow the movable block 12 to move up and down along the screw rod 3 until its height is adjusted to the same thickness as the workpiece.

[0031] In this preferred embodiment, the heigh...

Embodiment 3

[0033] This preferred embodiment provides an upper mold structure, which is basically the same as the first preferred embodiment. A plurality of balance weights are arranged at the edge of the bottom surface of the upper mold body of the upper mold structure.

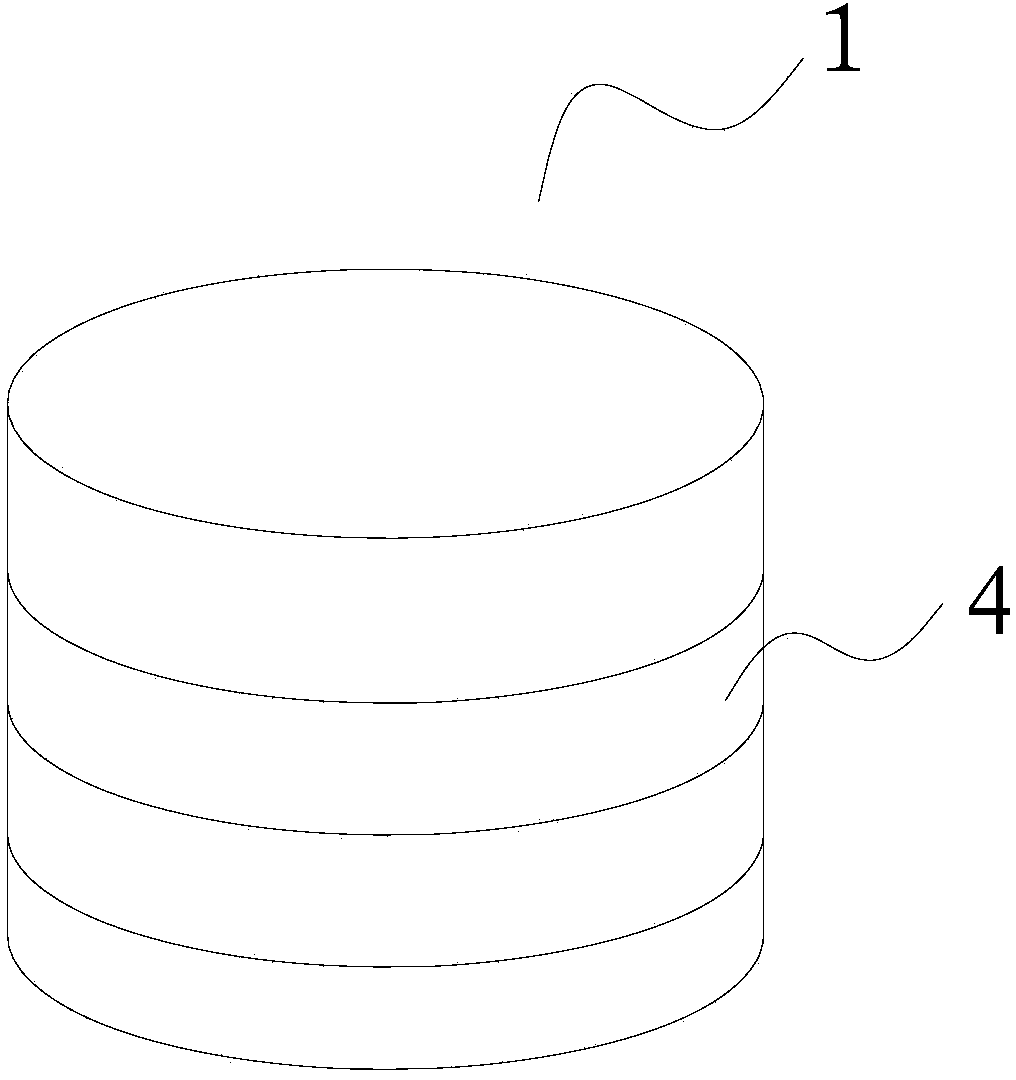

[0034] The difference is that: if image 3 As shown, the balance weight 1 is composed of at least one balance base block 4; the balance base block 4 is made of magnetic material, and at least two balance base blocks 4 can attract each other.

[0035] The thickness of the balance base block 4 is relatively thin, and a plurality of balance base blocks 4 can be sucked together to form a balance block 1 .

[0036] In this preferred embodiment, the height of the balance block 1 is adjusted by increasing or decreasing the number of balance base blocks 4, so that the height of the balance block 1 is the same as the thickness of the workpiece, and bears part of the pressure of the upper mold body to ensure a better processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com