Stamping die with drawing rib and forming technology of stamping die

A technology for stamping dies and drawbeads, which is applied in the field of stamping dies with drawbeads and its forming process, can solve the problems that fixed drawbeads cannot be adjusted, increase the cost of mold manufacturing, and reduce the service life of molds. The phenomenon of arc and rebound is obvious, the effect of prolonging the service life and improving the molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

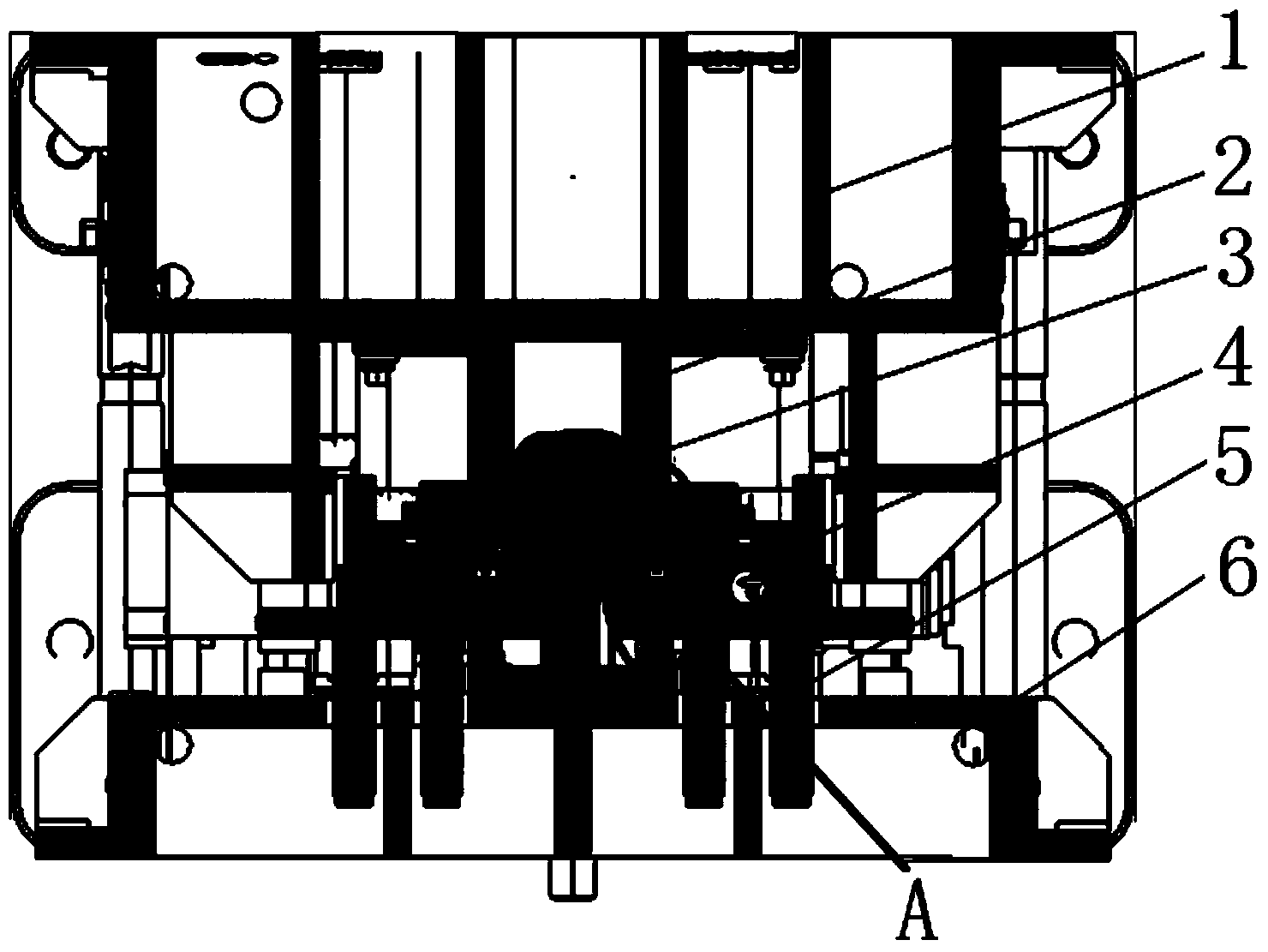

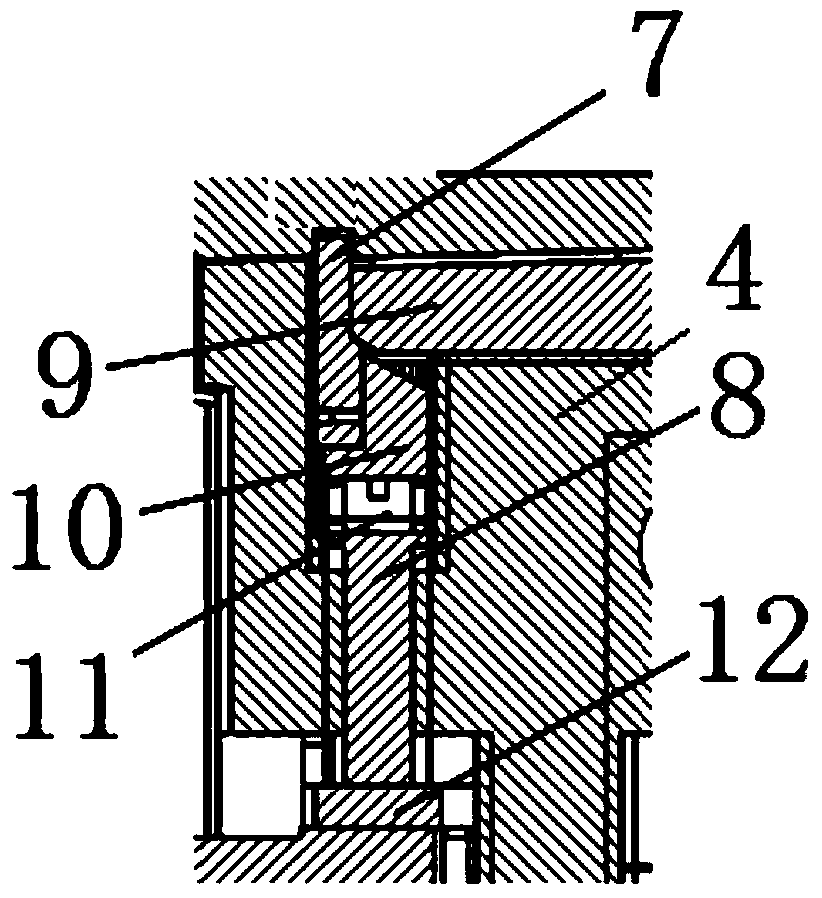

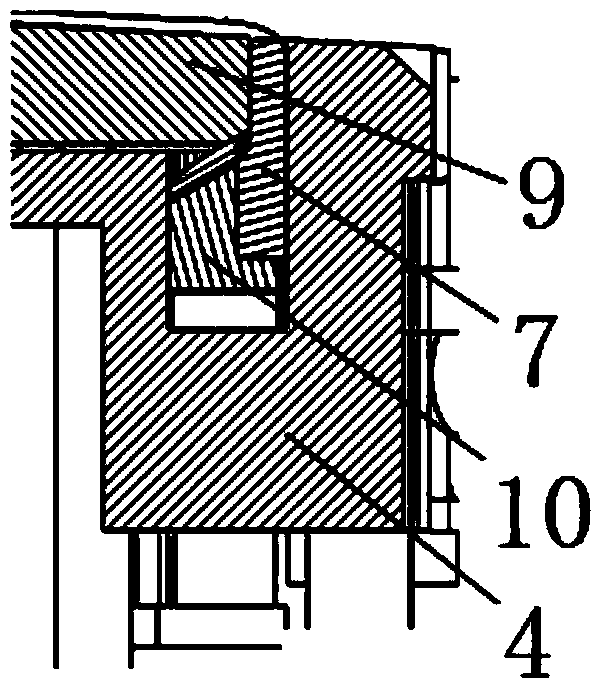

[0032] Such as Figure 1 to Figure 4 As shown, the stamping die with a drawbead includes an upper mold base 1, a lower mold base 6, a blank holder 4, a die 2, a punch 3, an air ejector pin 5 and a drawbead, wherein the die 2 It is fixedly arranged under the upper mold base 1, and the punch 3 is fixedly installed above the lower mold base 6 corresponding to the die 2. The lower end of the air ejector rod 5 is fixed on the lower mold base and is located under the blank holder 4, providing functions for the blank holder 4. Force, the blank holder is set outside the punch, and the upper surface of the blank holder corresponds to the edge of the die.

[0033] Wherein, the drawbead is a movable drawbead 7, and the movable drawbead 7 is slidably arranged in the chute in the blank holder 4, and the ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com