FDM (fused deposition modeling) technology-based 3D (three-dimensional) printer

A 3D printer and technical technology, applied in the field of FDM technology 3D printers, can solve the problems of restricting consumers' use of the market and scale, high purchase and maintenance costs, and uncompact structure, etc., to achieve convenient manual adjustment, compact structure, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

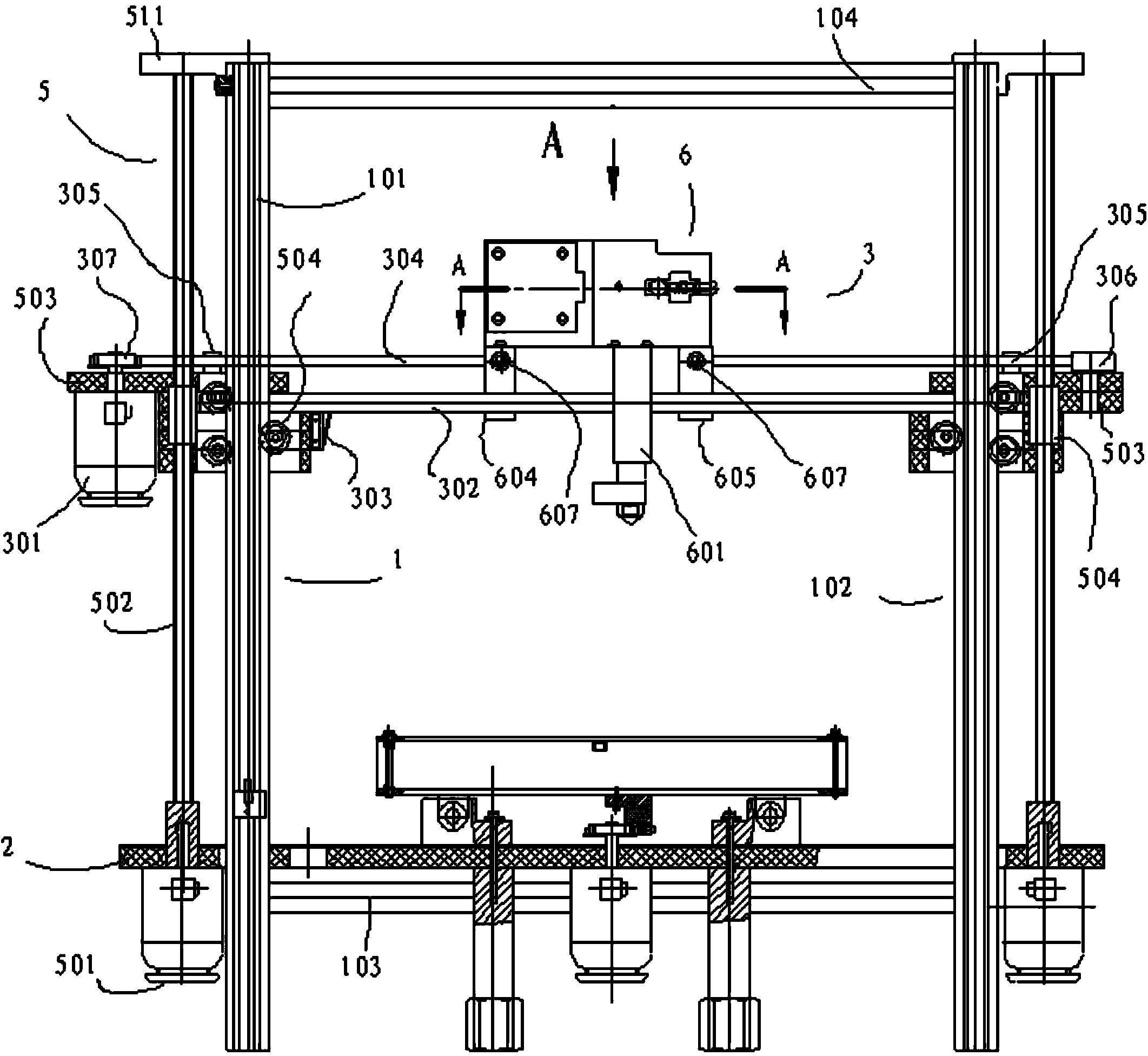

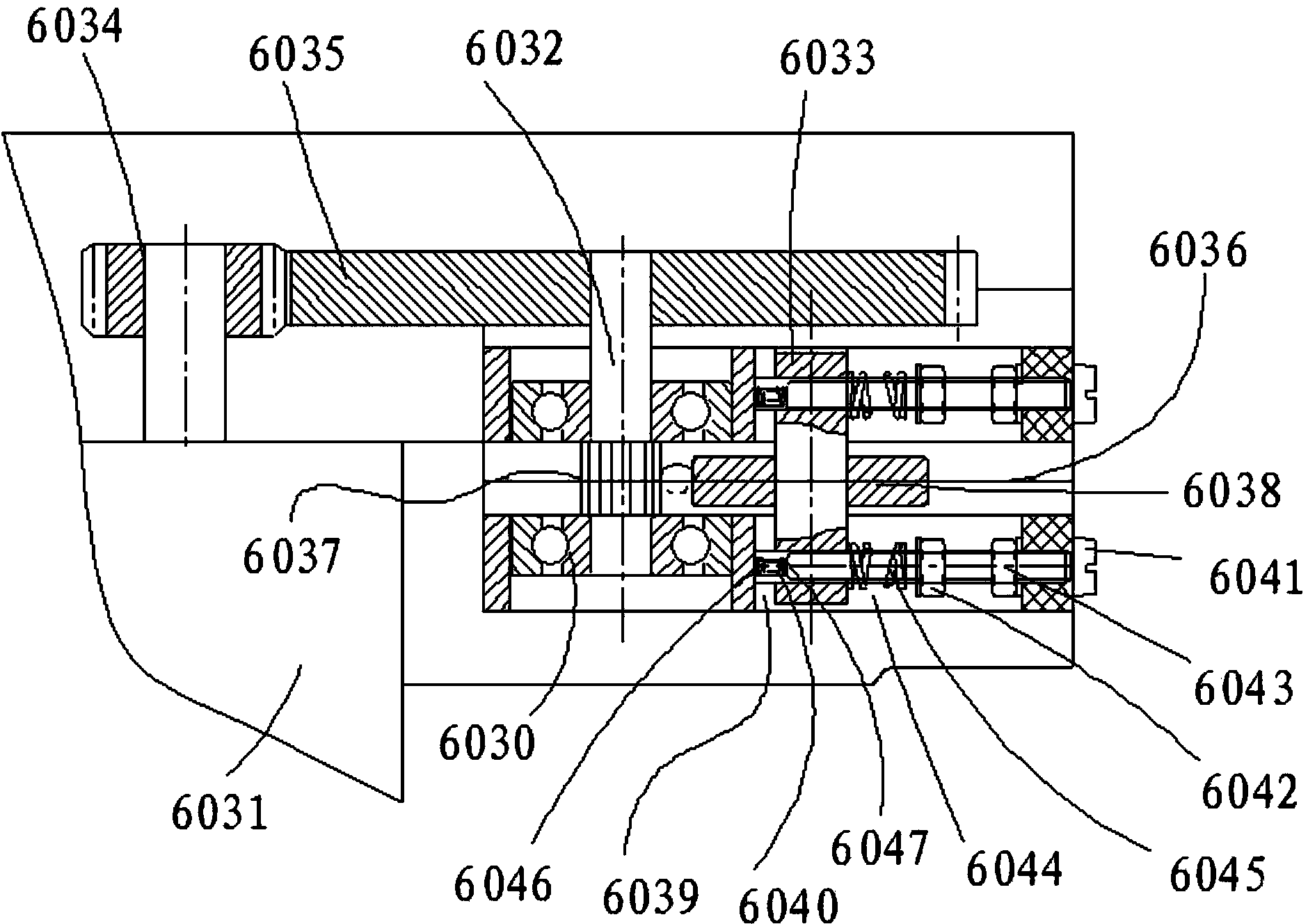

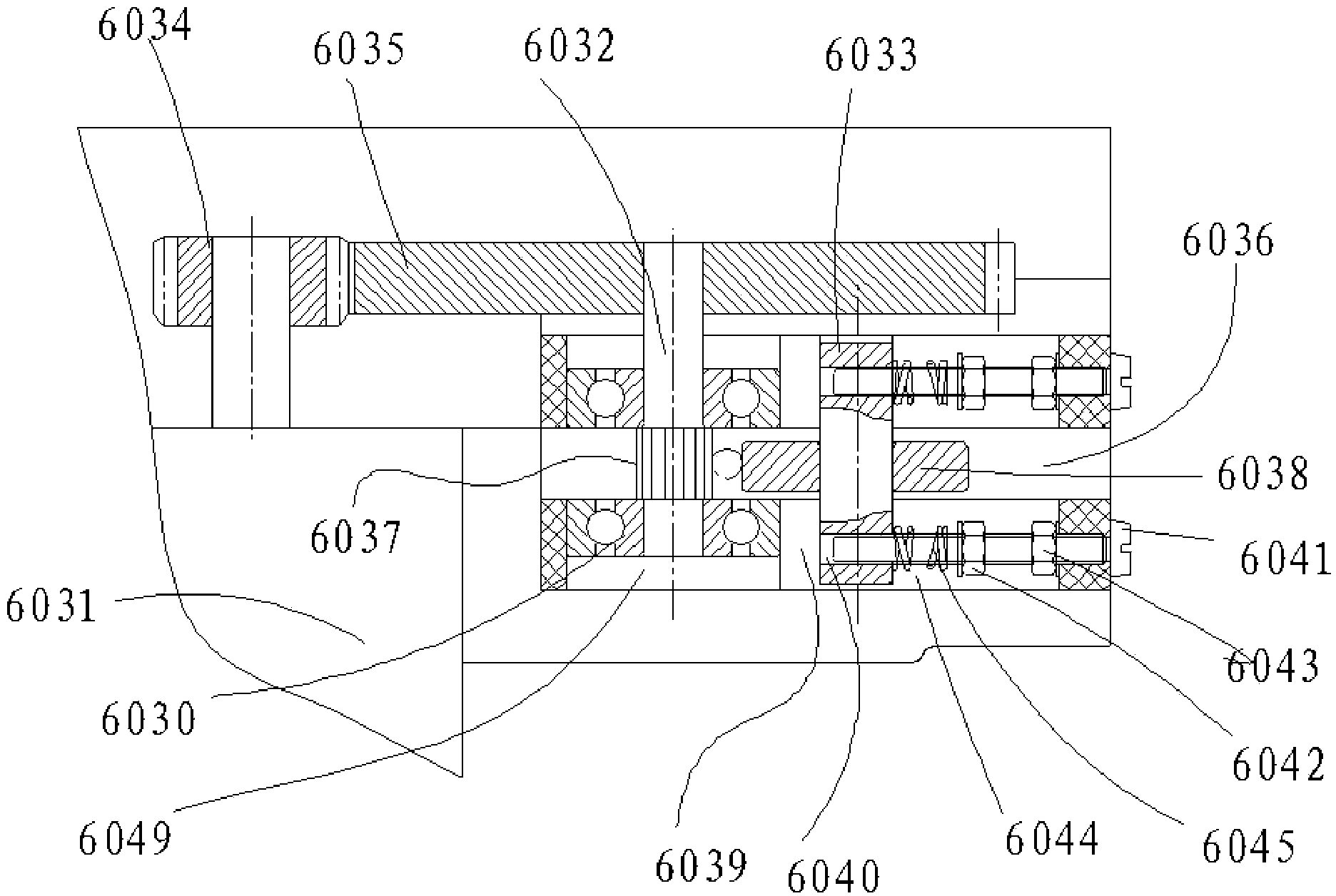

[0024] Such as Figure 1 to Figure 3 As shown, a FDM technology 3D printer includes a frame 1, a base 2, an X-axis moving system 3, a Y-axis moving system, a Z-axis moving system 5, and a printing device 6. The frame 1 includes left and right sides. Column 101, right column 102 and lower connecting plate 103, described lower connecting plate 103 is connected with left column 101, right column 102, base 2 is connected with lower connecting plate 103, described printing device 6 is connected with X-axis moving system 3, The X-axis moving system 3 is connected with the Z-axis moving system 5. The left column 101 and the right column 102 are provided with column guide rails, and the Z-axis moving system 5 is connected with the column guide rails. , the left lead screw and the right lead sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com