Remote-control cleaning machine

A cleaning machine and cleaning gun technology, which is applied in the field of cleaning machines, can solve the problems of increasing the cost and complexity of the manufacturing process, damaging the water pump and motor, endangering the safety of the operator, etc., achieving the effects of simple structure, prolonging the service life, and preventing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following descriptions are only preferred embodiments of the present invention, and do not limit the protection scope of the present invention. The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

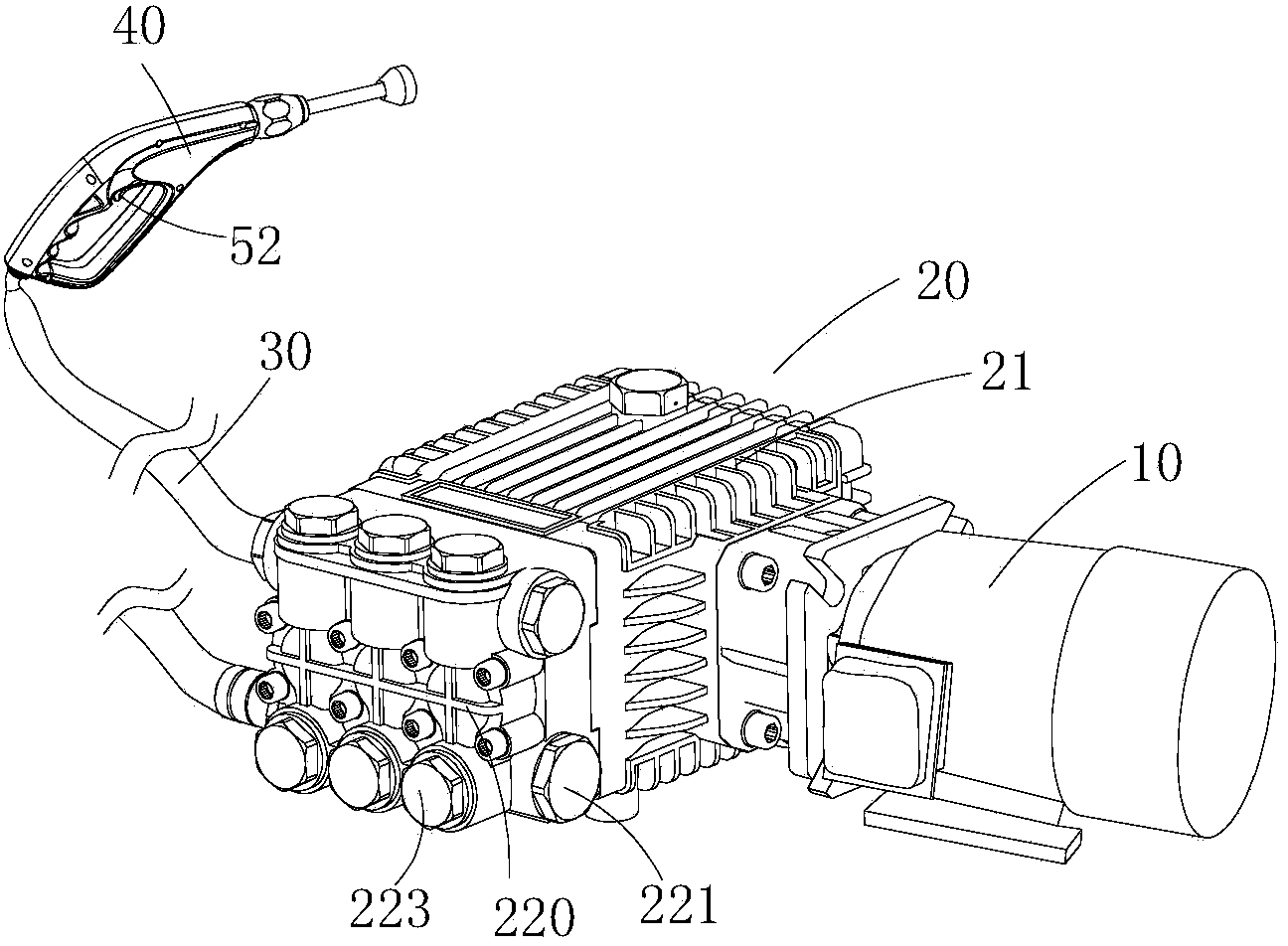

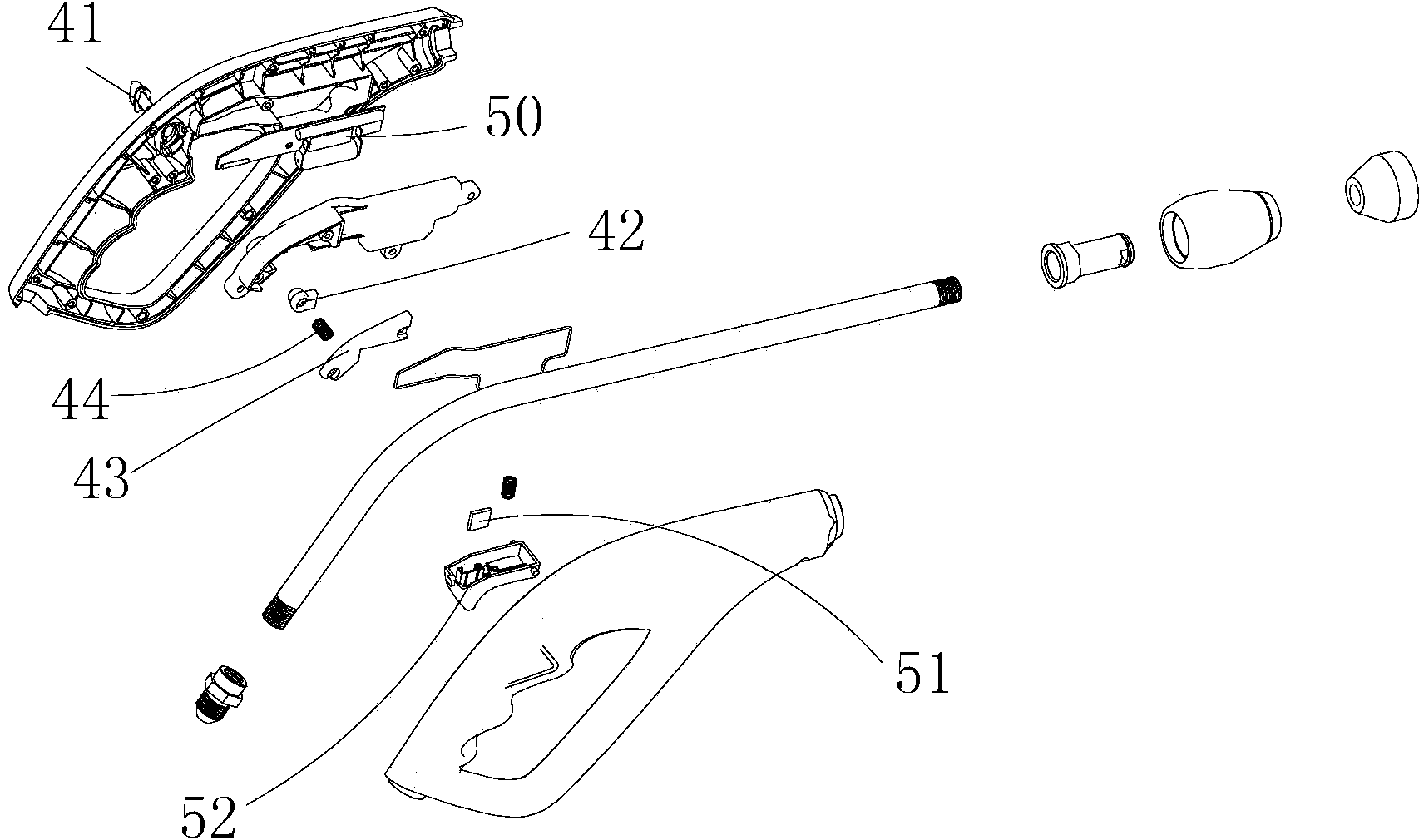

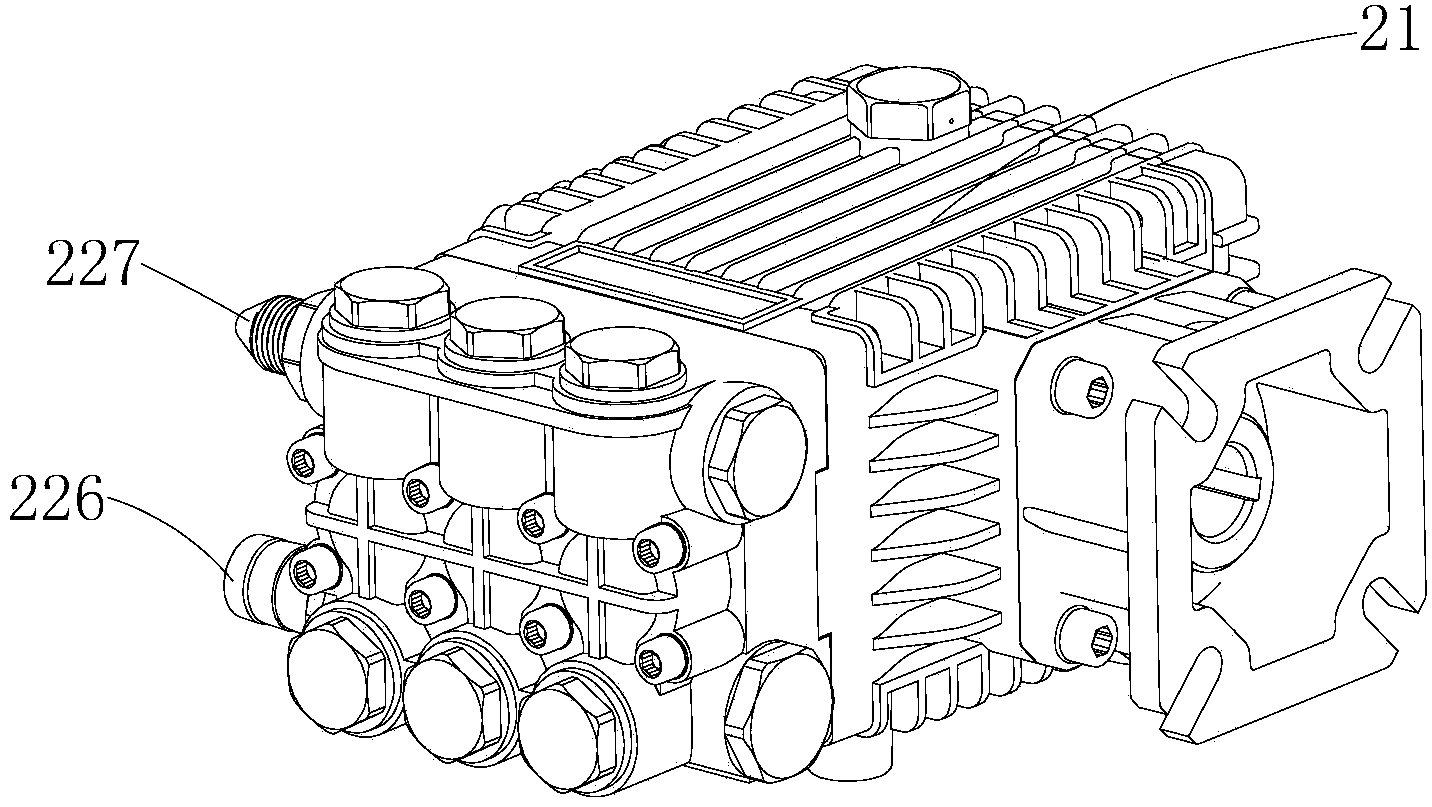

[0016] Examples, see Figure 1 to Figure 3 Shown: a remote cleaning machine, including a motor 10, a cleaning pump 20, a connecting water pipe 30, a frame and a cleaning gun 40, and the motor 10 and the cleaning pump 20 are fixed on the frame. The cleaning pump 20 includes a pump casing 21, a pump head 22 and a crankshaft connecting rod driving device arranged in the pump casing 21; the pump head 22 includes a cylinder body 220, a plug 221, a water sealing cap 223 and a water inlet and outlet valve; The water inlet and outlet valve 224 is arranged inside the cylinder body 220, and the plug 221 and the water sealing cap 223 cooperate with the drain port 225 on the cylinder body 220 respectively; The water ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com