Multi-machine two-stage compression cryogenic unit

A two-stage compression and compressor technology, applied to compressors, irreversible cycle compressors, refrigerators, etc., can solve the problems of short compressor life and high maintenance rate, save groundwater, improve operating conditions, and reduce water consumption cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

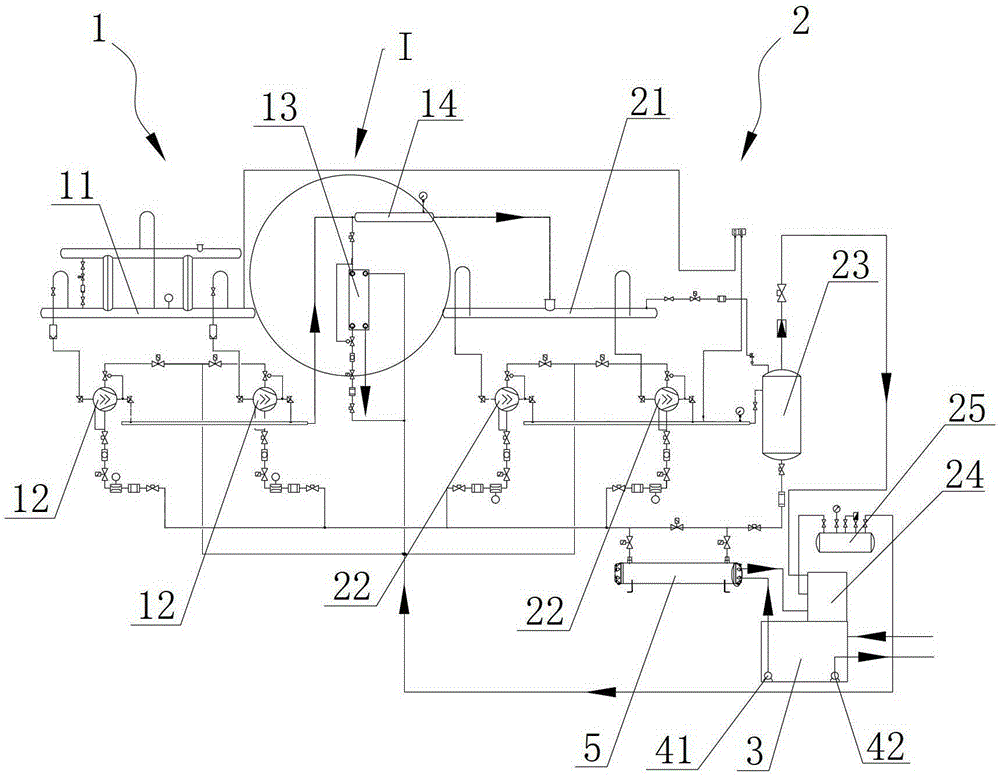

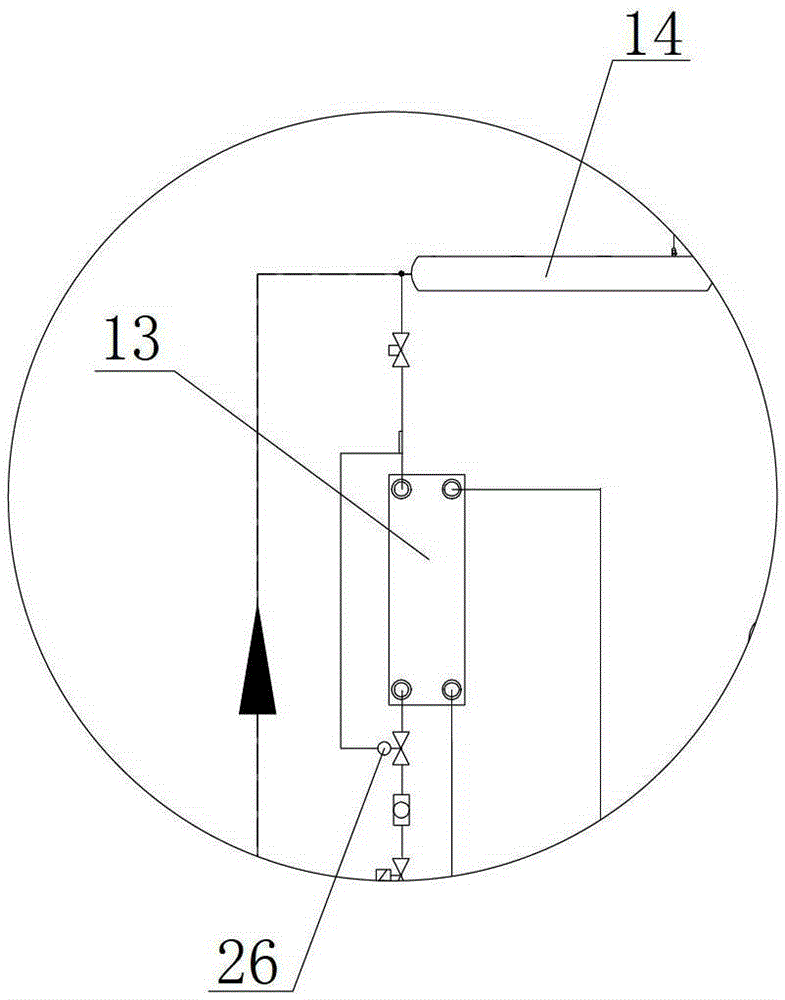

[0024] Such as figure 1 and figure 2 Commonly shown, it is an embodiment of the multi-machine two-stage compression cryogenic unit of the present invention. The two-stage referred to here includes a one-stage low-pressure compression device 1 and a two-stage high-pressure compression device 2, that is, the compression process is carried out in two stages . Its basic principle and advantages are: the temperature of the refrigerant discharged from the first-stage low-pressure compression is reduced to the saturation temperature under the pressure after being cooled by the mixing barrel, and then enters the second-stage compressor of the second-stage high-pressure compression part, thereby reducing the temperature of the second-stage compressor. The suction temperature of the compressor in the high-pressure compression part greatly improves the operating conditions of the second-stage compressor, avoiding various problems that are easy to occur in the single-stage refrigeration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com