A high-efficiency energy-saving oxygen blowing device for mining furnace

A high-efficiency energy-saving technology for furnaces, applied in furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of not enhancing the durability of oxygen blowing tubes, not being able to fully use up oxygen blowing tubes, and high production costs for oxygen enrichment alone , to achieve the effects of slow exhaustion, reduced energy consumption, and fast heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A high-efficiency energy-saving oxygen blowing device for mining and metallurgy furnaces, including an oxygen blowing pipe body 1, the oxygen blowing pipe body 1 is a hollow pipe body formed by pressing a metal material, the hollow pipe body has a thick-walled small hole, and the diameter of the inner hole is 16mm. The wall thickness is 11mm.

[0018] The metal material used in the oxygen lance body 1 has the following chemical composition by mass percentage: 0.12% carbon, 0.27% silicon, 7% manganese, 0.01% phosphorus, 0.01% sulfur, 7.0% chromium, 0.02% molybdenum, and the balance For Fe.

Embodiment 2

[0020] A high-efficiency energy-saving oxygen blowing device for mining and metallurgy furnaces, comprising an oxygen blowing pipe body 1, the oxygen blowing pipe body 1 is a hollow pipe body formed by pressing a metal material, and the hollow pipe body has a wall and other holes, and the diameter of the inner hole is 7mm. The wall thickness is 7mm.

[0021] The metal material used in the oxygen lance body 1 has the following chemical composition by mass percentage: 0.15% carbon, 0.28% silicon, 9% manganese, 0.02% phosphorus, 0.02% sulfur, 8.0% chromium, 0.022% molybdenum, and the balance For Fe.

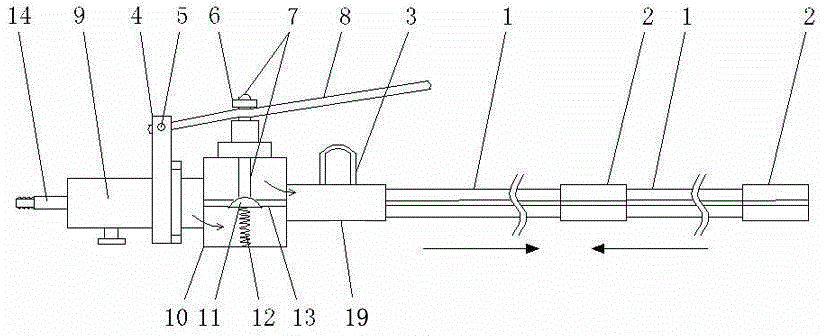

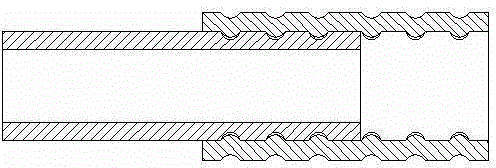

[0022] The end of the oxygen blowing pipe body 1 is provided with an oxygen blowing pipe supplementary body 2, the oxygen blowing pipe supplementary body 2 is a hollow pipe body, and the interference fit between the oxygen blowing pipe supplementary body 2 and the oxygen blowing pipe body 1, such as image 3 shown. The oxygen lance supplementary body 2 which is interference fit wi...

Embodiment 3

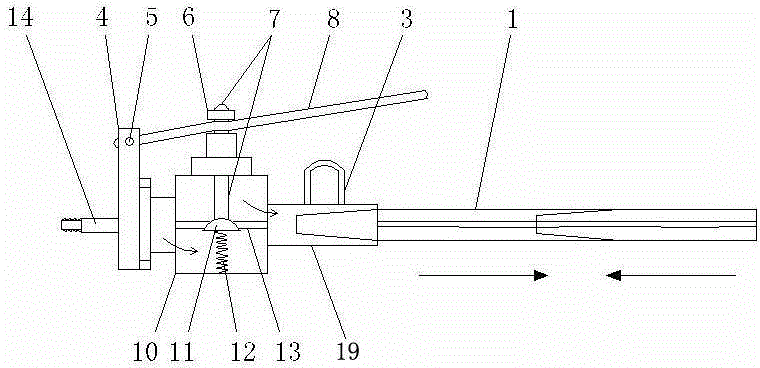

[0024] Such as figure 1 As shown, a high-efficiency energy-saving oxygen blowing device for mining and metallurgy furnaces includes an oxygen blowing pipe body 1. The oxygen blowing pipe body 1 is a hollow pipe body formed by pressing a metal material. The hollow pipe body has a thin wall and a large hole, and the diameter of the inner hole is It is 12mm and the wall thickness is 2mm.

[0025] The metal material used in the oxygen lance body 1 has the following chemical composition by mass percentage: 0.18% carbon, 0.29% silicon, 10% manganese, 0.035% phosphorus, 0.03% sulfur, 9.0% chromium, 0.025% molybdenum, and the balance For Fe.

[0026] The oxygen blowing tube body 1 is an oxygen blowing tube with a large and small head, and the two oxygen blowing tubes with small and large heads are connected in sequence from end to end and the joint adopts an interference fit.

[0027] The oxygen blowing pipe body 1 at the end is in interference fit with the oxygen lance muzzle 19 of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com