Bottom air bleeding type caseless ammunition

A caseless bullet and bullet tail technology, applied in the direction of warheads, ammunition, weapon accessories, etc., can solve the problems of overheating of the gun body, spontaneous combustion of bullets, etc., and achieve the effect of increasing the base of ammunition, reducing the volume and weight of the bullet, and simplifying the structure of the firearm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

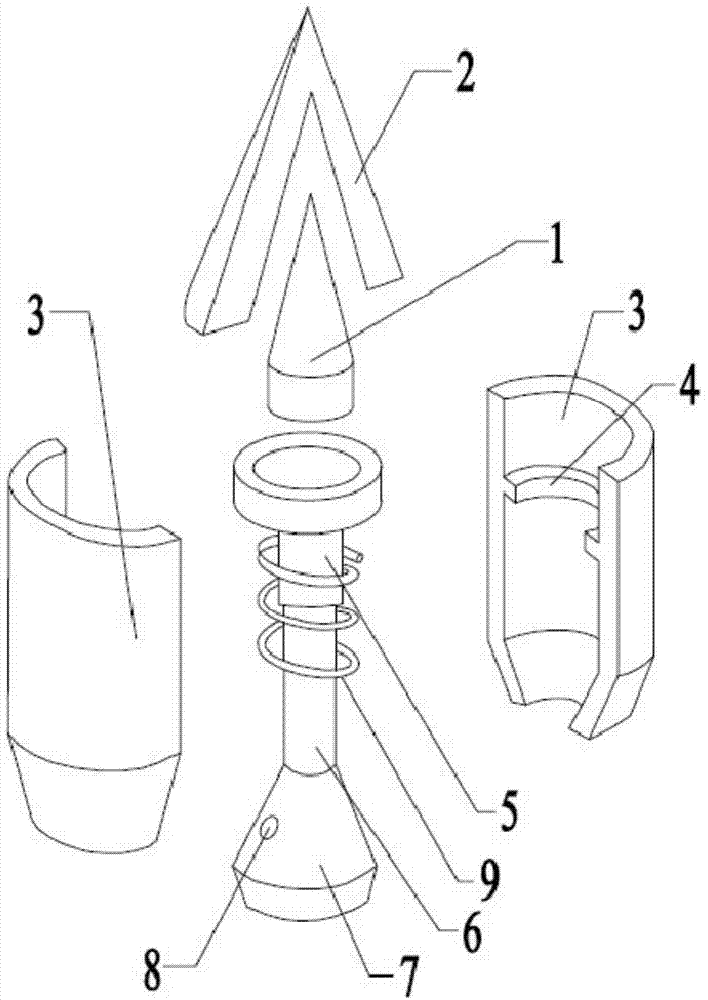

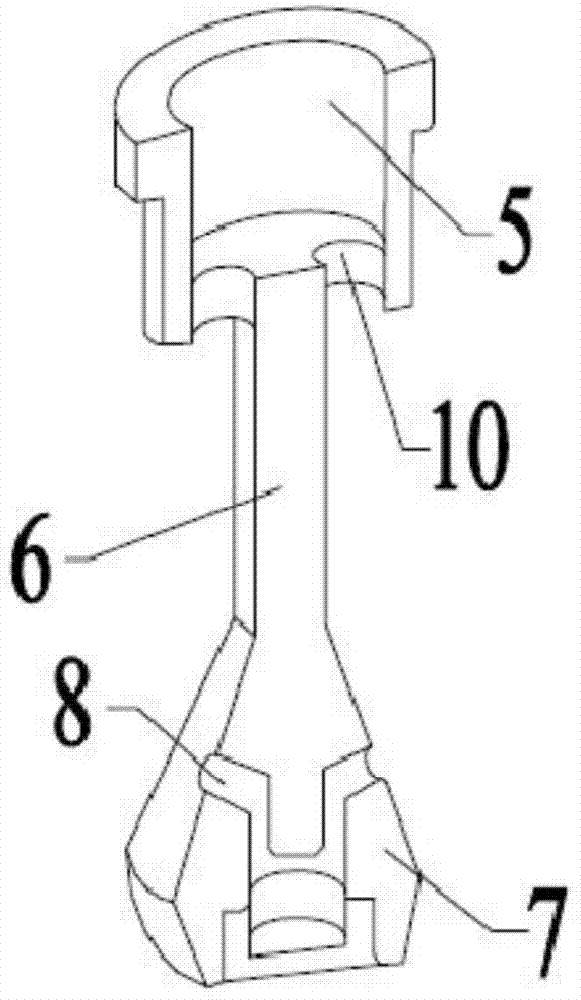

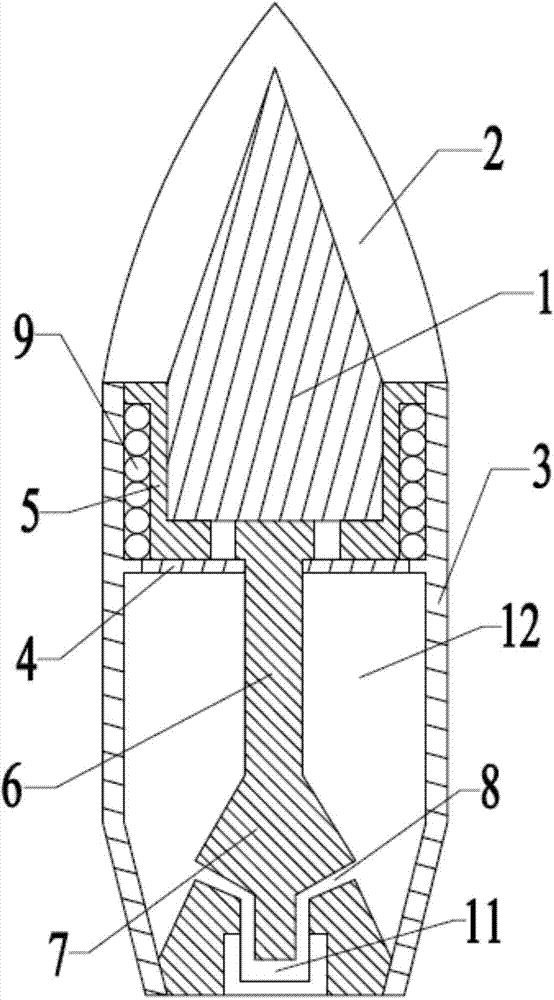

[0014] The invention provides a bottom deflated caseless bullet, such as figure 1 As shown, it includes bullet jacket 2, bullet core 1, piston cylinder 5, connecting rod 6 and bullet tail 7 arranged in sequence from top to bottom, the outside of piston cylinder 5 is sleeved with spring 9, and the outside of connecting rod 6 is provided with Cylindrical body 3 is provided with baffle plate 4 along the inner wall of body 3, the upper end of body 3 is connected with the lower end of bullet jacket 2, and one end of bullet core 1 is positioned in piston barrel 5; One end is positioned at the lower side of the upper edge of the piston barrel 5, the other end is positioned at the upper side of the baffle plate 4, the bottom of the bullet tail 7 is provided with a primer filling cavity 11, and the outside of the bullet tail 7 is provided with a fire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com