Bactericide for reverse osmosis membrane and method for preparing the same

A technology of reverse osmosis membrane and bactericide, which is applied in the field of bactericide for reverse osmosis membrane and its preparation, can solve the problems of increasing the cost of the agent, increasing the amount of the bactericide, and producing drug resistance of microorganisms, and improving the ability of sterilization and algae killing. , Best killing effect, excellent sterilization and algae killing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

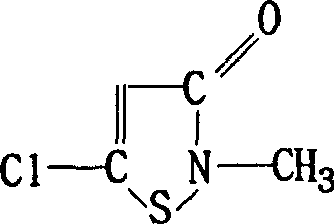

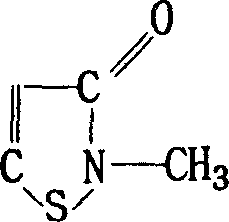

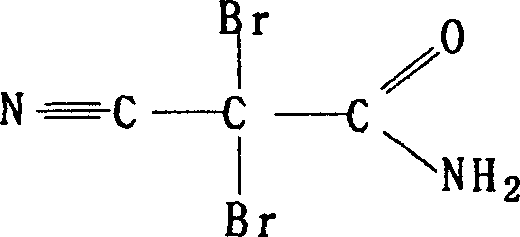

[0032] At room temperature, 200 grams of reverse osmosis product water, 100 grams of 1,3-propanediol, and 50 grams of 2,2-dibromo-3-nitrilopropionamide were added to the reactor and stirred for 20 minutes, and then 60 gram of bromonitro compound, 60 grams of isothiazolinone stock solution and stirred for 20 to 30 minutes to prepare the fungicide of the present invention.

Embodiment 2

[0034] According to the bactericide compounded in Example 1, the number of initial bacteria is 6×10 5 1 / ml of water samples were used for sterilization experiment, and the killing effect is shown in Table 1.

[0035] Fungicide / mgL -

[0036] According to the data listed in Table 1, when the bactericide dosage is 40mg / L, the bactericidal rate reaches 100%.

Embodiment 3

[0038] When the bactericide of the present invention is 2% of isothiazolinone, other conditions are constant, along with 2, the influence of bactericide on the bactericidal effect of the weight content variation of 2-dibromo-3-nitrilopropionamide is as table 2 shown

[0039] 2,2-Dibromo-3-nitrilo

Propionamide%

Bactericide Concentration for Reverse Osmosis Membrane

mg / L

Sterilization rate%

2

40

88

4

40

96

6

40

98

8

40

99

10

40

100

[0040] Note: The total number of blank heterotrophic bacteria is 5×10 5 pcs / ml

[0041] It can be seen from Table 2 that as the concentration of 2,2-dibromo-3-nitrilopropionamide increases, the bactericidal effect increases, and the optimal concentration has been reached when it is above 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com