A organic sulfur disinfection algicide and method for making same

A sulfur bactericidal algicide and organic technology, applied in the field of organic sulfur bactericidal algicide and its preparation, can solve the problems of reduced bactericidal ability, large environmental pollution, and small application range, and achieve good effect, good water solubility, and applicable wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

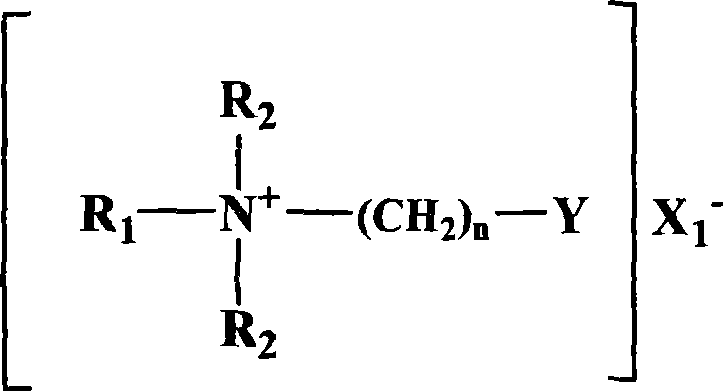

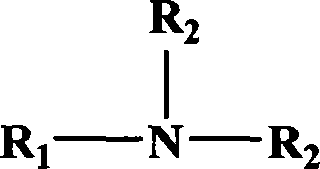

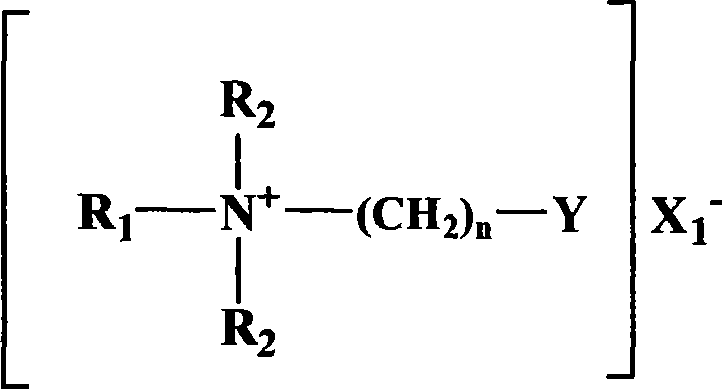

Method used

Image

Examples

Embodiment 1

[0041] In a 1000ml four-necked flask equipped with mechanical stirring, a constant pressure dropping funnel, a reflux condenser and a thermometer, add 190g (1.0mol) of dibromoethane, 5g of fatty alcohol polyoxyethylene ether and 150g of ethanol at room temperature, and start stirring 172 g (1.0 mol) of dodecyldimethyl tertiary amine was slowly added dropwise at a temperature not higher than 90° C., and after the addition was completed, the temperature was raised to reflux for reaction for 4 hours. After cooling down to below 70°C, slowly add 97g (1.0mol) aqueous solution of potassium thiocyanate dropwise, and react for 4 hours after the addition to obtain the organosulfur bactericide and algicide (OSB1) of the present invention.

Embodiment 2

[0043] In a 1000ml four-necked flask equipped with mechanical stirring, a constant pressure dropping funnel, a reflux condenser and a thermometer, add 190g (1.0mol) of dibromoethane, 5g of fatty alcohol polyoxyethylene ether and 150g of ethanol at room temperature, and start stirring , at a temperature not higher than 90°C, slowly add 228g (1.0mol) of hexadecyldimethyl tertiary amine dropwise, after the addition is completed, the temperature is raised to reflux for reaction for 4 hours. After cooling down to below 70°C, slowly add 72g (1.0mol) of potassium hydrosulfide aqueous solution dropwise, and react for 4 hours after the addition to obtain the organosulfur bactericide and algicide (OSB2) of the present invention.

Embodiment 3

[0045] In a 1000ml four-necked flask equipped with mechanical stirring, a constant pressure dropping funnel, a reflux condenser and a thermometer, add 205g (1.0mol) of dibromopropane, 8g of fatty alcohol polyoxyethylene ether and 180g of isopropanol at room temperature, and open the Stir, and slowly add 172 g (1.0 mol) of dodecyldimethyl tertiary amine dropwise at a temperature not higher than 90°C. After the addition is completed, the temperature is raised to reflux for 4 hours. After cooling down to below 70°C, slowly add 97g (1.0mol) aqueous solution of potassium thiocyanate dropwise, and react for 4 hours after the addition to obtain the organosulfur bactericide and algicide (OSB3) of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com