Silver-loaded low-molecular-weight chitosan composite microsphere antibacterial agent and preparation method thereof

A low-molecular-weight, composite microsphere technology, applied in the fields of botanical equipment and methods, biocides, disinfectants, etc., can solve the problem of large particle size of microspheres, and achieve the effect of simple preparation process, high lethality, and avoidance of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

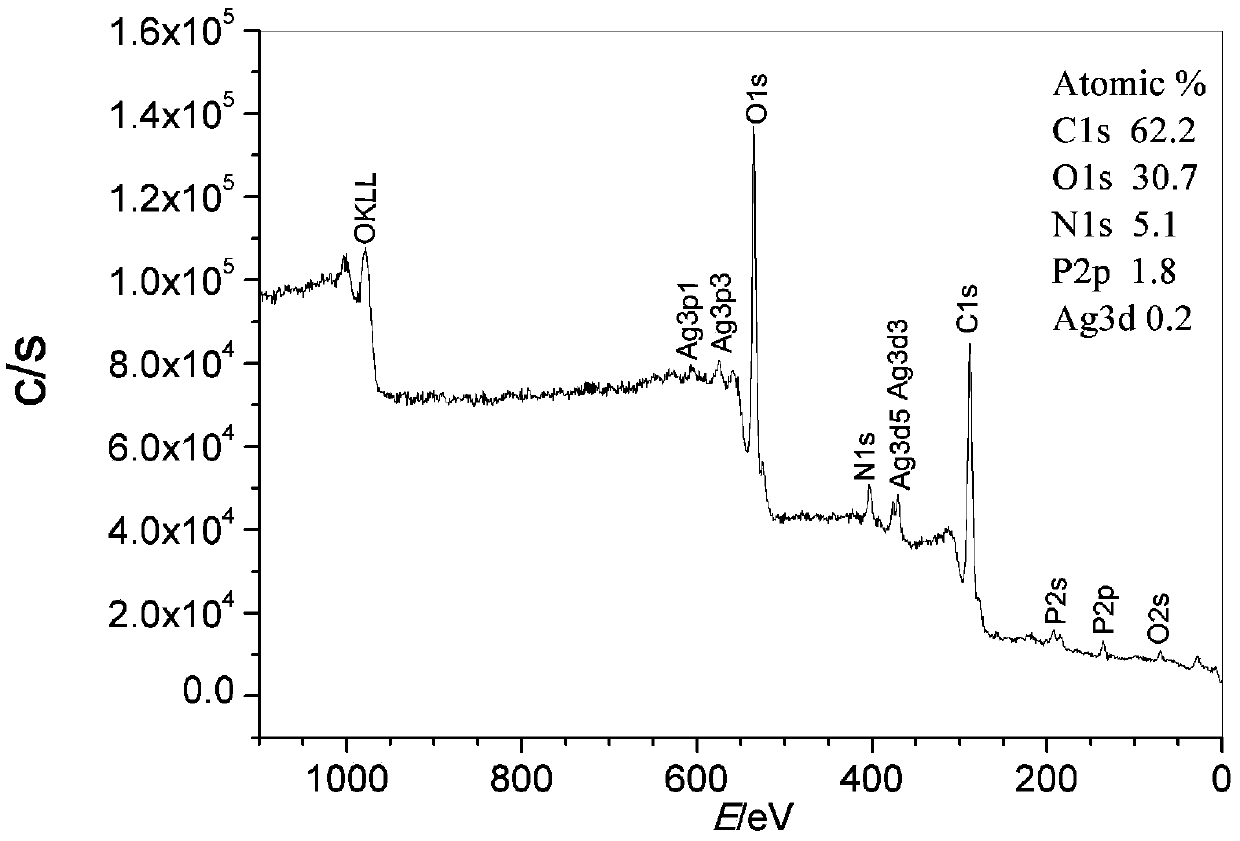

[0051] Add 2.00g of chitosan with a deacetylation degree of 90% to 50mL of 20.0g / L acetic acid aqueous solution, stir well and let it stand overnight until completely dissolved; Stir continuously for 3h to degrade chitosan. The degraded chitosan was precipitated with 30 mL of 20% NaOH aqueous solution, washed successively with 40 mL of deionized water and 20 mL of absolute ethanol, and dried at 80 °C to constant weight to obtain a viscosity-average molecular weight of 6.0×10 5 low molecular weight chitosan.

[0052] Dissolve 0.40g of low molecular weight chitosan in 20mL of 10.0g / L acetic acid aqueous solution, add dropwise 1mL of silver nitrate aqueous solution with a concentration of 0.2mol / L, stir for 30min, and then add dropwise a vanillin solution with a concentration of 50.0g / L (solvent volume ratio: V 水 :V 乙醇 =1:2) 2mL, continued to stir for 1h to obtain silver / low molecular weight chitosan composite latex.

[0053] According to sorbitan monooleate (Span-80) and alk...

Embodiment 2

[0060] Add 2.00g of chitosan with a deacetylation degree of 90% to 50mL of 20.0g / L acetic acid aqueous solution, stir well and let it stand overnight until completely dissolved; Stir continuously for 3h to degrade chitosan. The degraded chitosan was precipitated with 30 mL of 20% NaOH aqueous solution, washed successively with 40 mL of deionized water and 20 mL of absolute ethanol, and dried at 80 °C to constant weight to obtain a viscosity-average molecular weight of 4.3×10 5 low molecular weight chitosan.

[0061] Dissolve 0.40g of low molecular weight chitosan in 20mL of 10.0g / L acetic acid aqueous solution, add dropwise 1mL of silver nitrate aqueous solution with a concentration of 0.3mol / L, stir for 30min, and then add dropwise a vanillin solution with a concentration of 50.0g / L (solvent volume ratio: V 水 :V 乙醇 =1:2) 2mL, continued to stir for 1h to obtain silver / low molecular weight chitosan composite latex.

[0062] According to sorbitan monooleate (Span-80) and alk...

Embodiment 3

[0065] Add 3.00g of chitosan with a deacetylation degree of 90% to 50mL of 20.0g / L acetic acid aqueous solution, stir well and let it stand overnight until completely dissolved; Stir continuously for 3h to degrade chitosan. The degraded chitosan was precipitated with 50 mL of 20% NaOH aqueous solution, washed successively with 50 mL of deionized water and 20 mL of absolute ethanol, and dried at 80 °C to constant weight to obtain a viscosity-average molecular weight of 3.3×10 5 low molecular weight chitosan.

[0066] Dissolve 0.40g of low molecular weight chitosan in 20mL of 10.0g / L acetic acid aqueous solution; add dropwise 1mL of silver nitrate aqueous solution with a concentration of 0.3mol / L, stir for 30min, and then add dropwise a vanillin solution with a concentration of 50.0g / L (solvent volume ratio: V 水 :V 乙醇 =1:2) 3mL, continued to stir for 1h to obtain silver / low molecular weight chitosan composite latex.

[0067] According to sorbitan monooleate (Span-80) and alk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com