A Dynamic Calibration Device for Pressure Measuring Sensor in Gun Bore

A measurement sensor and dynamic calibration technology, which is applied in the direction of measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of reduced pressure measurement accuracy and poor calibration accuracy in the gun bore, and achieve improved impact pressure, high work efficiency, and meet the requirements of increased pressure. The effect of pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

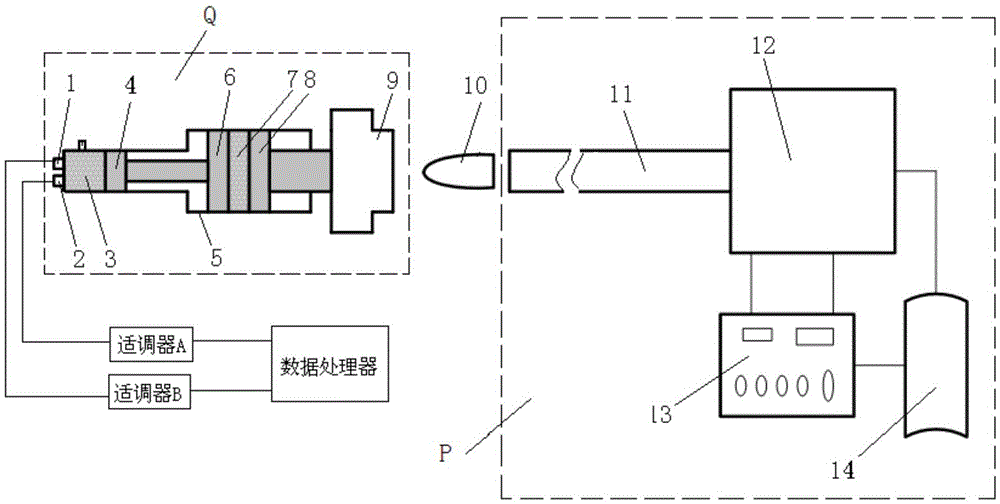

[0013] Referring to the accompanying drawings, it has an air cannon (P) and a percussion supercharger (Q) opposite to the air cannon. A standard pressure sensor (1) and a calibrated pressure supercharger are installed on the percussion supercharger. For the sensor (2), the signal output ends of the standard pressure sensor and the calibrated pressure sensor are respectively connected to a data processor through an adapter A and an adapter B. The air cannon is a mature technology, and generally includes a gun barrel (11), a high-pressure chamber (12), a pressure console (13) and an air source (14). When firing, put the projectile (10) into the gun barrel, then set the speed of the projectile through the pressure console, and control the air pressure in the high-pressure chamber according to the setting, so that it will generate instantaneous high pressure, thereby pushing the projectile to the set The motion speed of the shot.

[0014] Referring to the drawings again, the impa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com